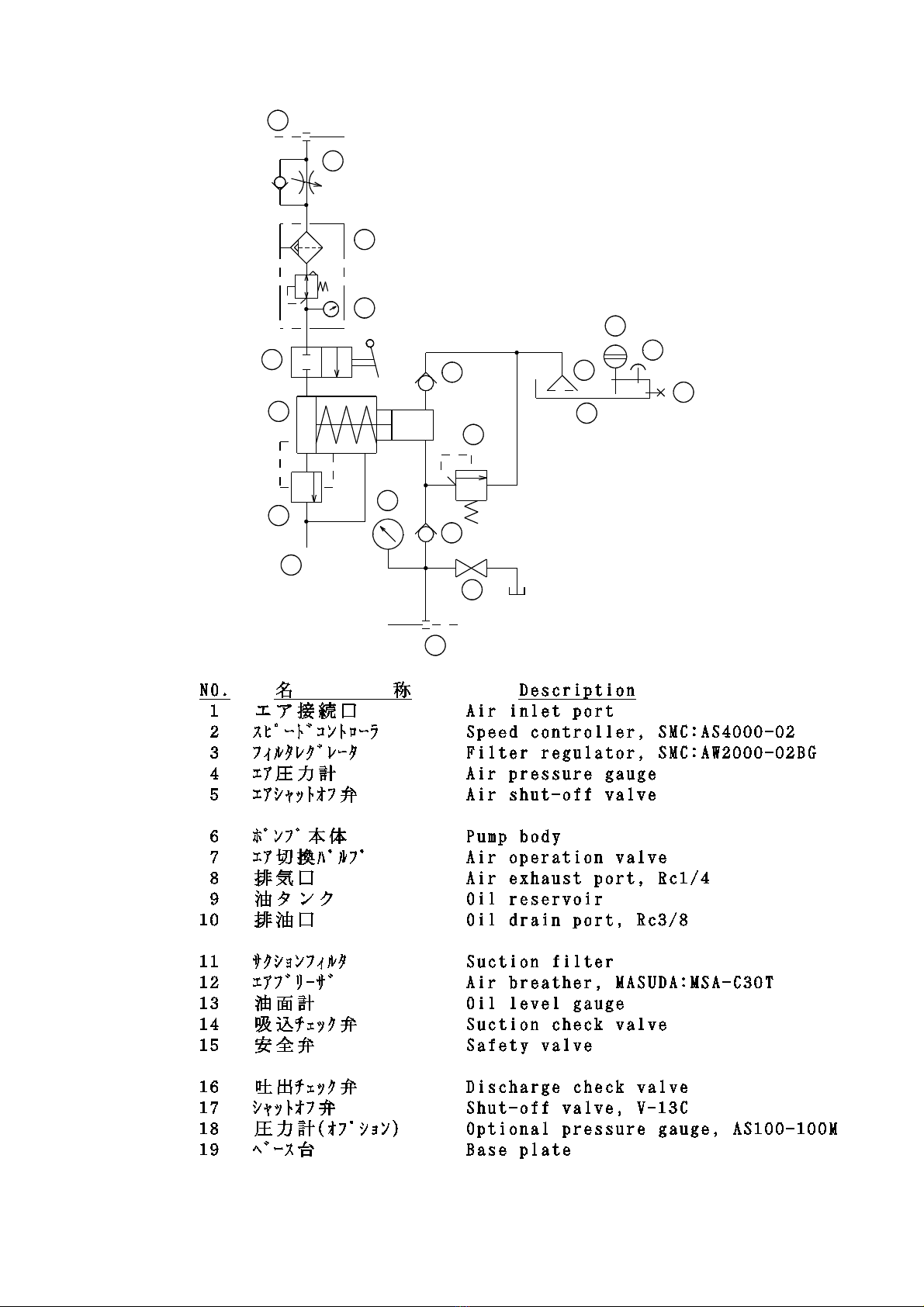

!"#$%&'( ")*++,)* -',-*

A gauge to measure a oil pressure (Optional).

!$( %,#",# "%)#

A port from which 70MPa oil is displaced. Port size is Rc3/8(PT3/8).

.'+* "('#*

A base plate to stable and fix the pump body.

/0 1"*2$3$2'#$%&+

!"#$%& '()*+),-

./$001/$ /23456& ./472/8 0326$ 9:4/; ) <=** 3" <=> !.2?*=@ 3" >=, A6BCD7 E

F

G$D"5#2/8 0326$ 9'4%; ) >< !.2?>,H A6BCD7 E

F

'4% "13I13C745& <=- D7 C03/"A$

J

K42= "B I403"5& - 77

L$0$/M"4/ D2I2D438& ,- %3/0=

N02O%$ "4%& ,F %3/0=

P$46Q3 2II/"R=& H* A60=

P"/A456 "4%& +8#/21%4D S"/A456 "4% TG' UVJF 9G+'P: G+WXX YWXXNG ZJF[ !'\TX KYW

'TX XTV+Y[ WGG' N(T.'PWL JF[ "/ $]14M2%$53;

40 5',#$%&+

678 .*3%)* '""(9$&- ")*++,)*: #';* %,# #<* =($&> "(,- %3 #<* %$( %,#",# "%)#:

#<*& ?%,&# ' <%+* %) ' 2%,"(*)0

6@8 A<* ?'B$?,? %"*)'#$&- ")*++,)* %3 #<$+ ",?" $+ CDEF'GC7H;-3I2? J0

@

K$-< ")*++,)* +'3*#9 L'(L*: M<$2< M%);+ '+ ' +'3*#9 >*L$2*: $+

3'2#%)9!+*# '# CDEF'GC7H;-3I2? J0 .* +,)* &%# #% '>N,+# #<$+ L'(L* '# *B2**>$&- #<$+

@

")*++,)*0

6O8 P3 #<$+ ",?" $+ ,+*> #% %"*)'#* #<* "*)$"<*)'(+: M<%+* %"*)'#$&-

")*++,)* $+ (*++ #<'& CDEF': +*#K$-< ")*++,)* +'3*#9 L'(L* '# #<*

"*)$"<*)'(+Q %"*)'#$%& ")*++,)*0 P3 &%#: #<* "*)$"<*)'(6+8 ?$-<# =* >'?'-*>0 1** "'-* 7D

K%M #% R>N,+# K$-< F)*++,)* 1'3*#9 S'(L*0

6H8 A';$&- '22$>*&#+ $&#% 2%&+$>*)'#$%&: 2,# %33 #<* '$) +%,)2* =*3%)* #<*

?'$&#*&'&2* %3 #<$+ ",?"0

6/8 T+* P1! SUO@ <9>)',($2 M%);$&- %$( %&(90 F<%+"<'#* *+#*):

M'#*)!-(92%( '&> MI% *?*)+$%& %$( +<%,(> &%# =* ,+*>0 A<* "'2;$&- +*'(+ M$(( =*

>*#*)$%)'#*> '&> #<* *V,$"?*&# M$(( =* 2%))%>*> #% 2',+* #)%,=(*+ %3 #<$+ ",?"0 P3 9%, M%,(>

($;* #% ,+* #<*+* %$(: 2%&+,(# WPXYZ %) WPXYZQ+ ',#<%)$[*> '-*&#+0

648 \% &%# ,+* <$-< ")*++,)* +'3*#9 L'(L* '+ ' )*($*3 L'(L*0 P&+#'((

)*($*3 L'(L* '>>$#$%&'((9: +% '+ #% 2%&#)%( #<* ")*++,)* =9 )*($*L$&- %$(

2%&#$&,%,+(90

(7) The oil temperature should be 5 to 60 C.^

(8) Dusts are enemy of hydraulic system. Always keep oil clean, so as to avoid the machine trouble.

(9) Change working oil at least once a year.

C0 K%M #% P&+#'((

(1) Install this pump on a safe and flat place.

(2) Pump and cylinder(s) are connected by use of high pressure hose(s) or steel pipe(s).

R8A% 2%&&*2# =9 ,+* %3 #<* <$-< ")*++,)* <%+*+

Normally, the one end of the 70MPa high pressure hose is screwed in

the output port of the pump,

another end has a hose side coupler to connect a cylinder side coupler.

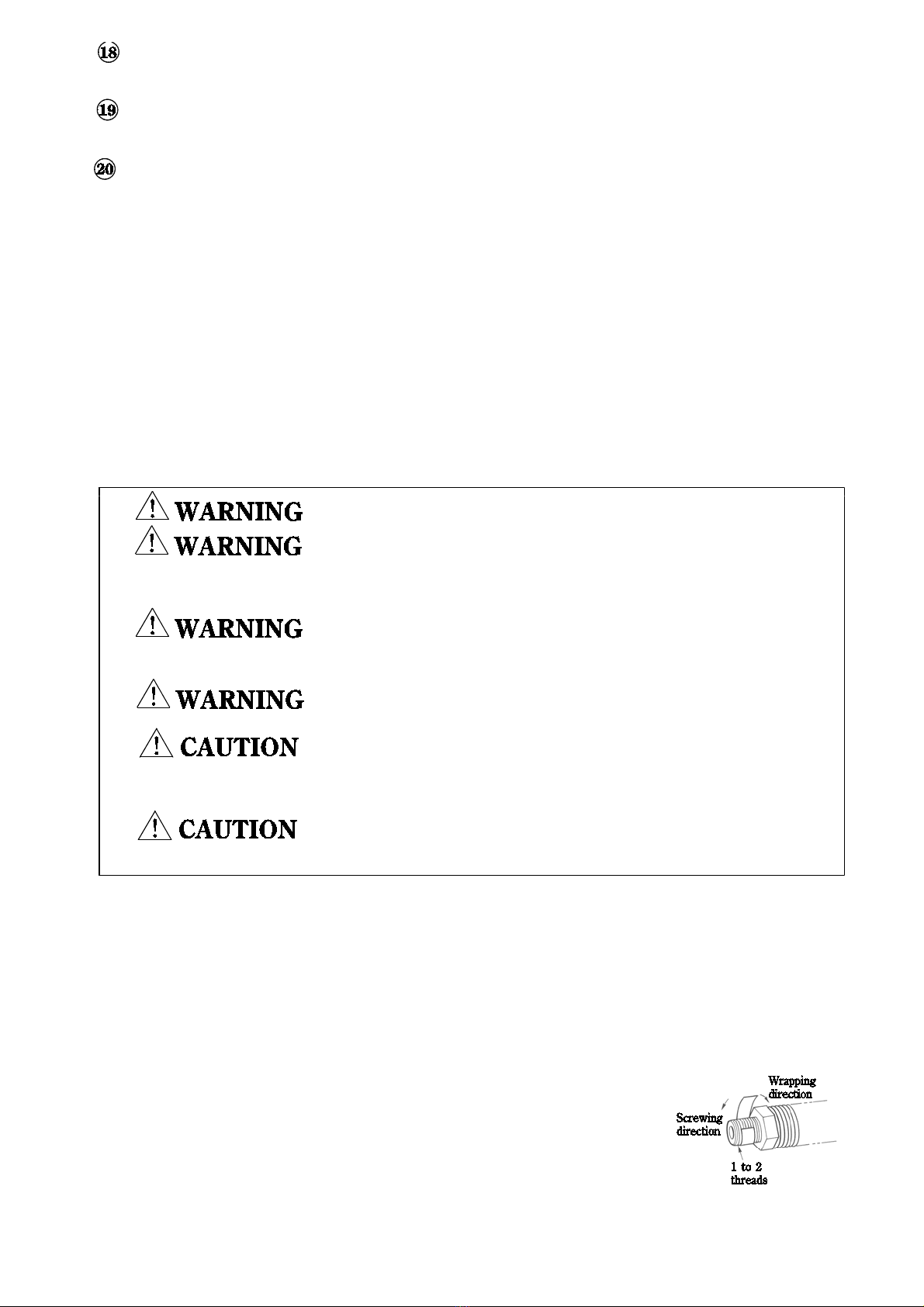

K%M #% M)'" #'"* +*'(!

Use 1 to 2 wraps of tape seal on each R3/8(PT3/8) thread counter-

clockwise by leaving 1 to 2 threads from the end of the thread. One

end of the thread is to be screwed in Rc3/8(PT3/8) output port of

the pump.

- 7 -