2001475_D

i

Contents

Introducon ..................................................................................................................................................... 1

About this User Guide ................................................................................................................................................................................... 1

About Your Product ....................................................................................................................................................................................... 1

Important Informaon ..................................................................................................................................... 3

Support Informaon ...................................................................................................................................................................................... 3

Learn More Online ........................................................................................................................................................................................ 3

Technical Support .......................................................................................................................................................................................... 3

Opcal Disc Recording Soware Disclaimer .................................................................................................................................................. 4

Safety and Compliance Informaon .............................................................................................................................................................. 4

Safety Precauons ..................................................................................................................................................................................... 4

Compliance Informaon ............................................................................................................................................................................ 5

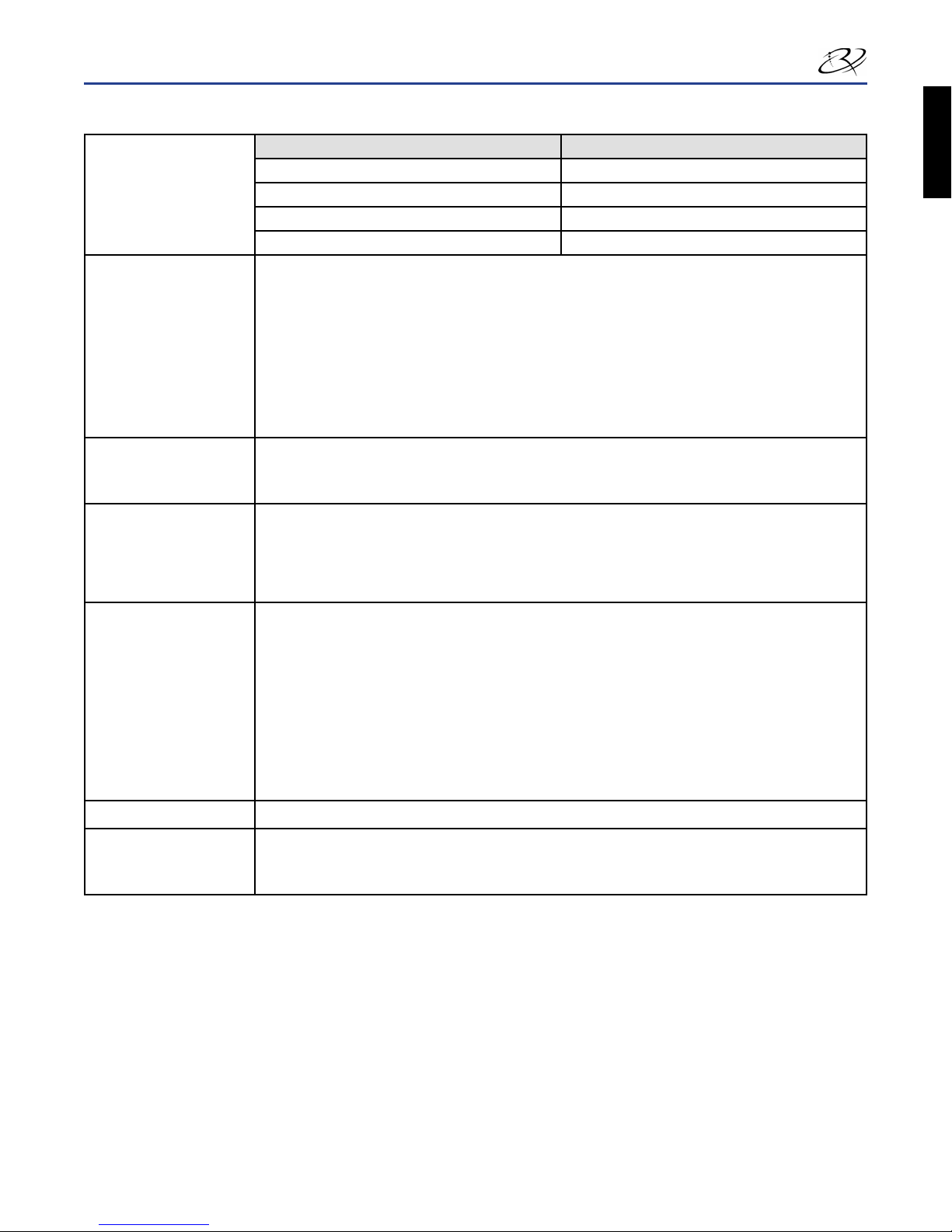

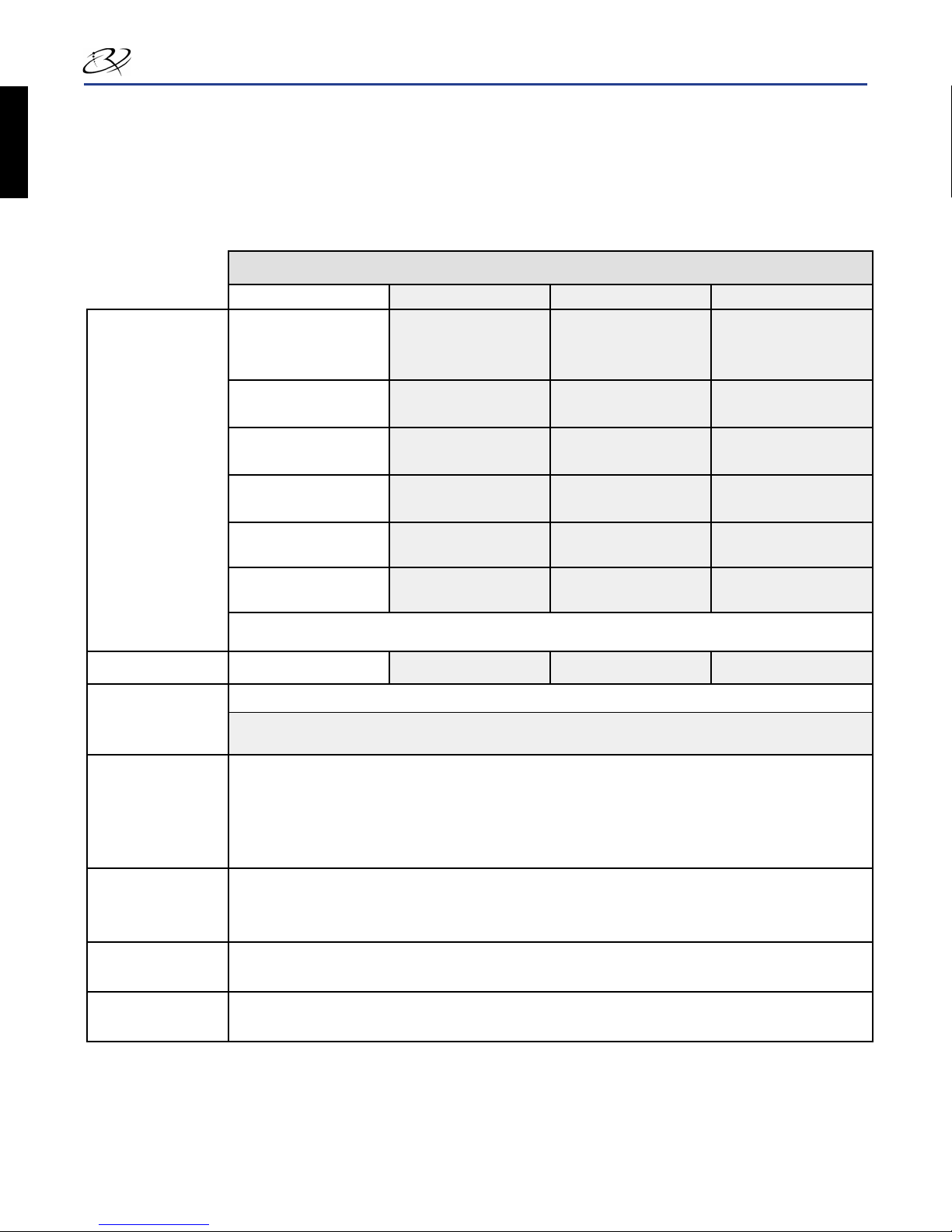

Producer III Specicaons ............................................................................................................................................................................. 6

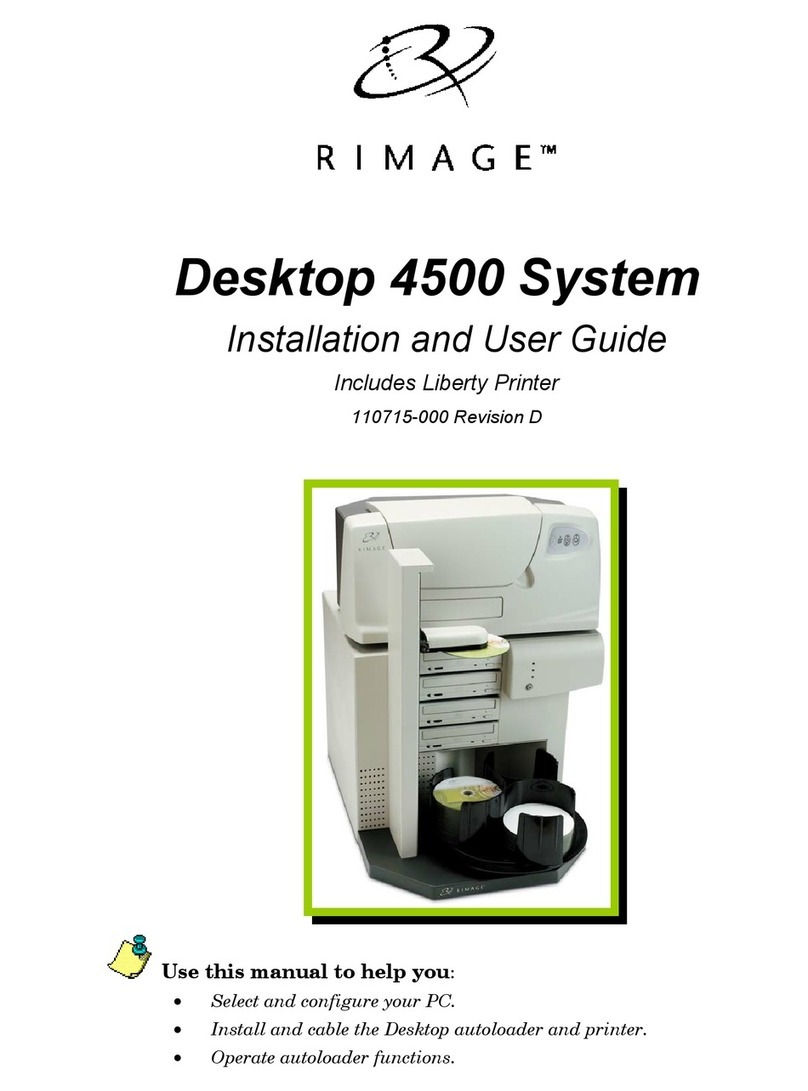

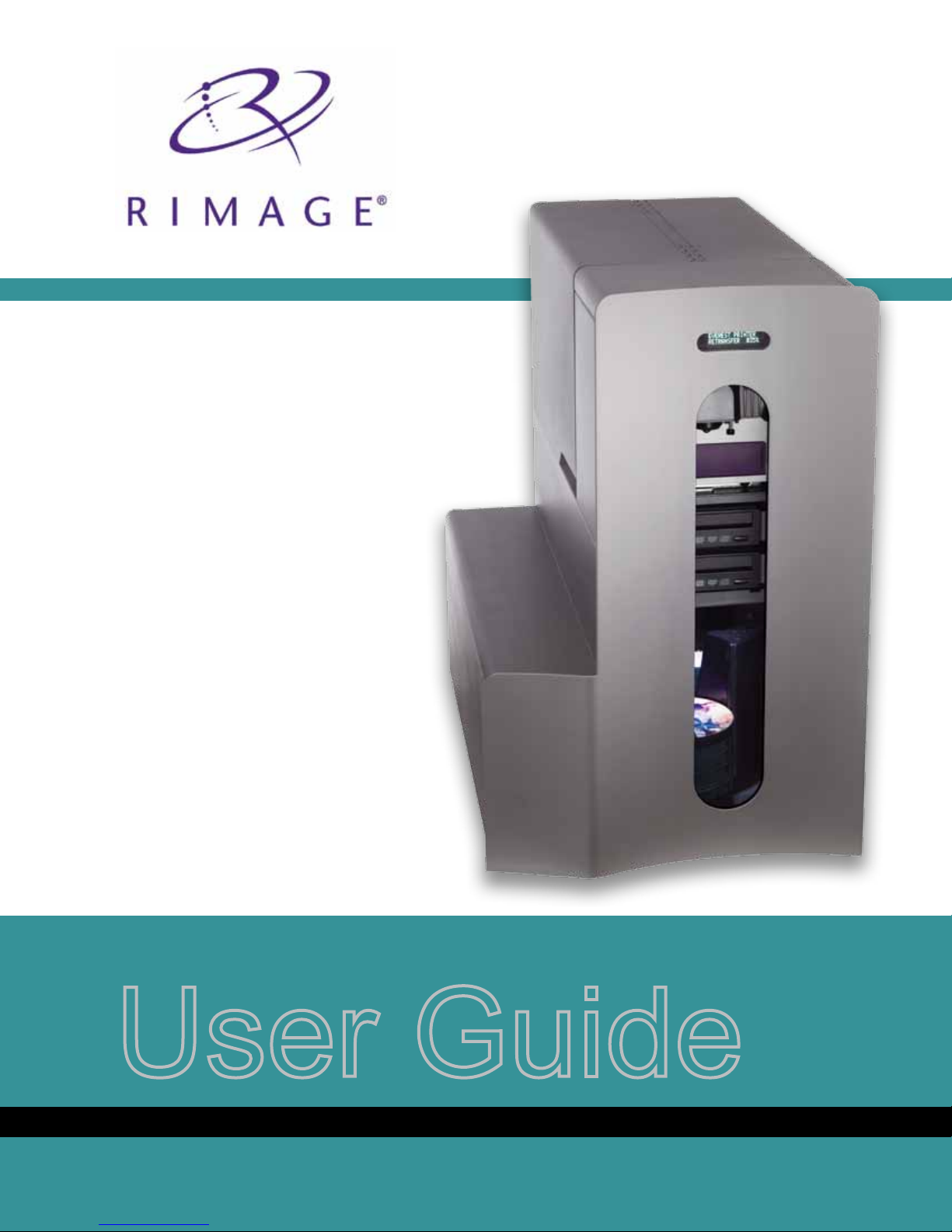

Idenfy the Parts of the Producer III................................................................................................................. 9

Front View ..................................................................................................................................................................................................... 9

Back View .................................................................................................................................................................................................... 10

Parts Informaon......................................................................................................................................................................................... 11

Status Light .............................................................................................................................................................................................. 11

Operator Panel ........................................................................................................................................................................................ 11

Operator Buon ...................................................................................................................................................................................... 11

Disc Dispenser (6100, 6100N, and 8100N Only) ...................................................................................................................................... 11

Beeper ..................................................................................................................................................................................................... 11

Operate the Producer III ................................................................................................................................. 12

Power On the Producer III ........................................................................................................................................................................... 12

Power O the Producer III ........................................................................................................................................................................... 12

Pause the Producer III ................................................................................................................................................................................. 12

Install the Carousel ...................................................................................................................................................................................... 13

Remove the Carousel .................................................................................................................................................................................. 13

Load the Discs .............................................................................................................................................................................................. 14

Unload the Discs .......................................................................................................................................................................................... 14

Set Your Prinng Preferences ...................................................................................................................................................................... 14

Maintain the Producer III................................................................................................................................ 15

Overview ..................................................................................................................................................................................................... 15

Cauonary Informaon ............................................................................................................................................................................... 15

Preventave Maintenance Schedule ........................................................................................................................................................... 15

Diagnosc Tests ........................................................................................................................................................................................... 16

Access and Select Diagnosc Tests .......................................................................................................................................................... 16

Access Diagnosc Mode ................................................................................................................................................................................................ 16

Select a Diagnosc Test .................................................................................................................................................................................................. 16

Exit Diagnosc Mode ............................................................................................................................................................................... 17

Diagnosc Test 1 – Carousel Diagnosc Test ........................................................................................................................................... 17

Check the Posion of the Carousel ................................................................................................................................................................................ 17

Check the Alignment of the Li Arm to the Carousel .................................................................................................................................................... 17

Diagnosc Test 3 – Calibrate Diagnosc Test ........................................................................................................................................... 18

Calibrate the Li Arm ..................................................................................................................................................................................................... 18

Calibrate the Carousel .................................................................................................................................................................................................... 19

Align the Printer .......................................................................................................................................................................................... 20

Operate Gemini Ulies ................................................................................................................................. 23

Start Gemini Ulies ................................................................................................................................................................................... 23

Change the Autoloader Display Name ........................................................................................................................................................ 23

Enable the Beeper ....................................................................................................................................................................................... 23

English