Touch Controller Kit

Scope

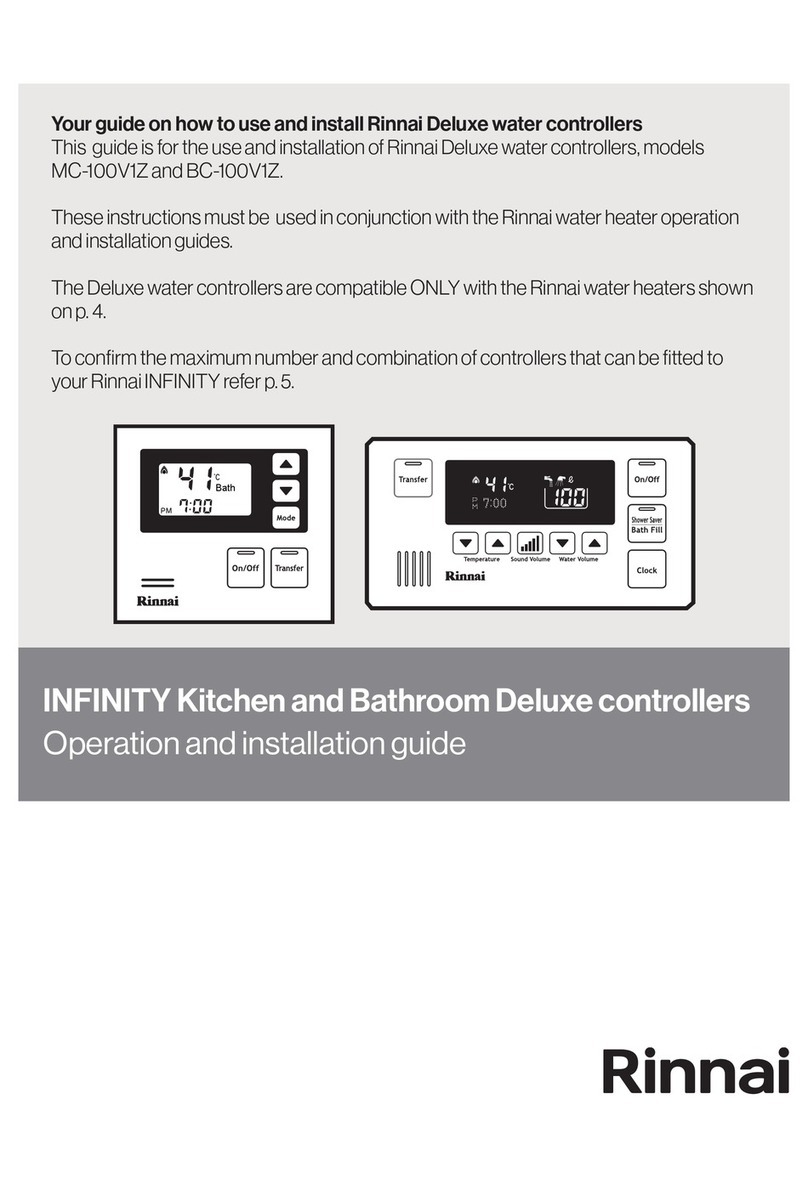

Please read these instructions carefully before installing this

product. This manual covers the installation of the wall mounted

Touch Controller for the following applications:

•Gas Ducted Heating

•Gas Ducted Heating & Refrigerated Cooling (Dual Comfort)

•Evaporative Cooling

•Zoning, including ZonePlus

For the installation of Heating and Cooling products please refer to

the equipment Installer Manuals.

This manual is based on Australian Standards - for all other

applications, please refer to relevant local codes and regulations.

Any deviations from these instructions may, at the discretion of the

company, void the warranty. As a result, the customer and/or

installer may be charged a fee for non-product warranty related

call outs. Also, note that failure to comply with these instructions

may preclude the company from being able to service the product.

Terminology:

Shall: Indicates a mandatory requirement of this manual.

Should: Indicates a recommended requirement of this manual.

Disclaimer

IMPORTANT NOTICE: This document is a guide only. Laws, regulations and industry standards can

vary between States and Territories. Accordingly, this guide must be read in conjunction with, and

subject to, all laws, regulations and industry standards applicable in the State or Territory in which the

products are installed. You must ensure that the installation of the products will comply with

those laws, regulations and standards, and that the products recommended to customers are

fit for the purpose for which they are intended.

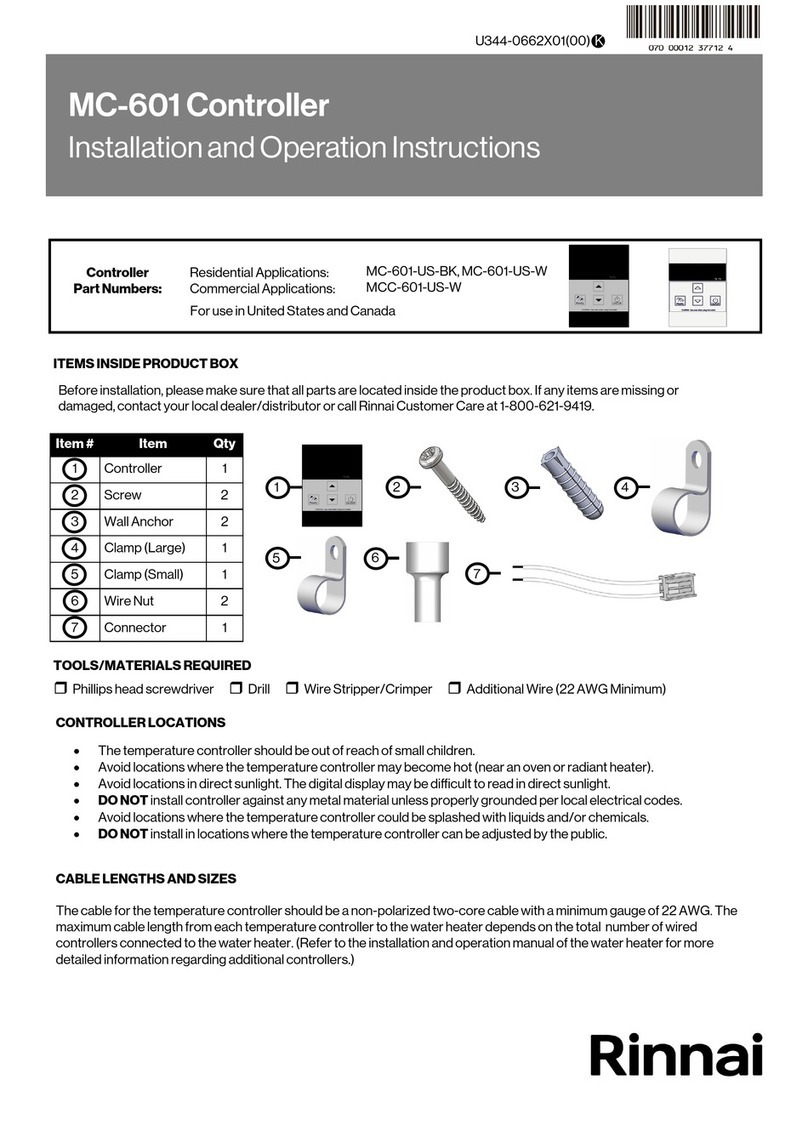

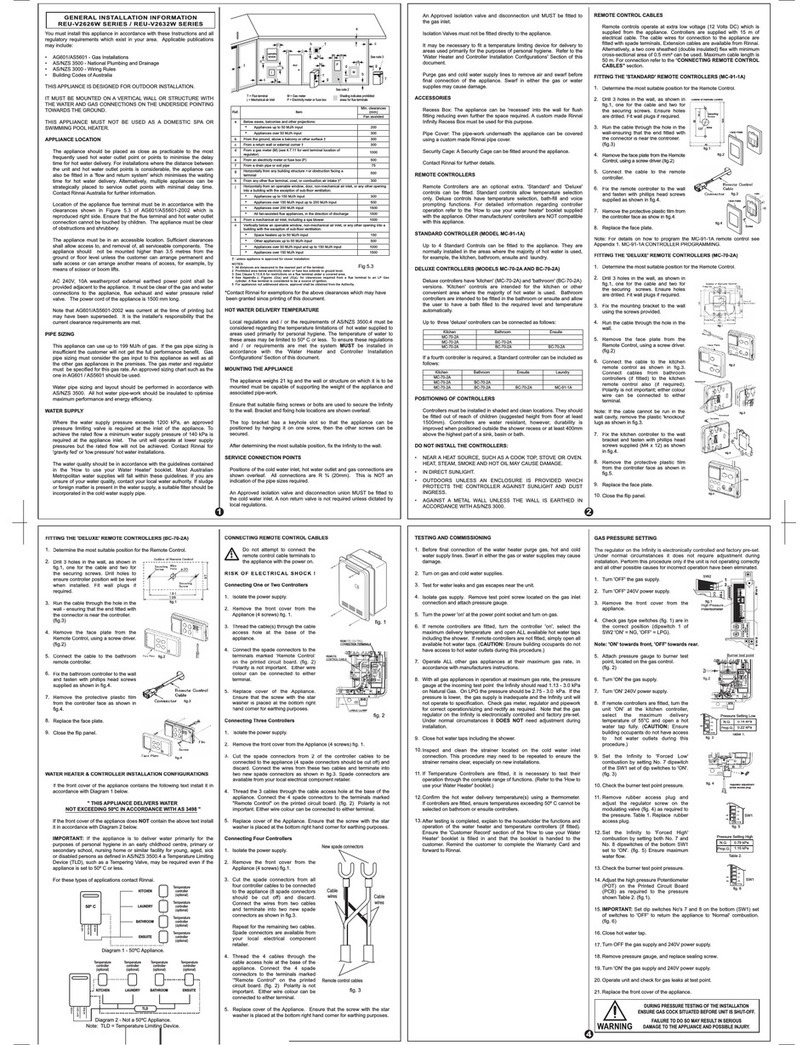

Table 1: Touch Controller Kit Part No. B063047

Touch Controller 1

Interface Module 1

Power Transformer 1

Power & Communication Loom 1

Plug & Screw Kit (for Touch) 1

Screw (for Interface Module)

Screw Driver 1

Inspect the product to ensure it matches your order. In the event of

damage or incorrect delivery, notify the supplier immediately. The

company accepts no responsibility for installation of damaged or

incorrect product.

Please read these installation instructions before undertaking the

installation process.

Specifications subject to change without notice. Pictures for illustration purposes only.

© Brivis Climate Systems Pty Ltd 2020

All rights reserved. No part of these documents may be used in any way or form without prior written

consent from Brivis Climate Systems Pty Ltd.

•The Touch Controller is compatible with selected units only.

For information on compatibility please contact your Dealer.

•Your Touch Controller is compatible with the Rinnai Touch App,

however they are independent items. An additional Wi-Fi accessory

must be installed and configured to enable Wi-Fi functionality.

•Pre-2010 compatible heaters will have limited on-board diagnostics.