Reference Manual – Software 2.x

Page 4 004R-613-153

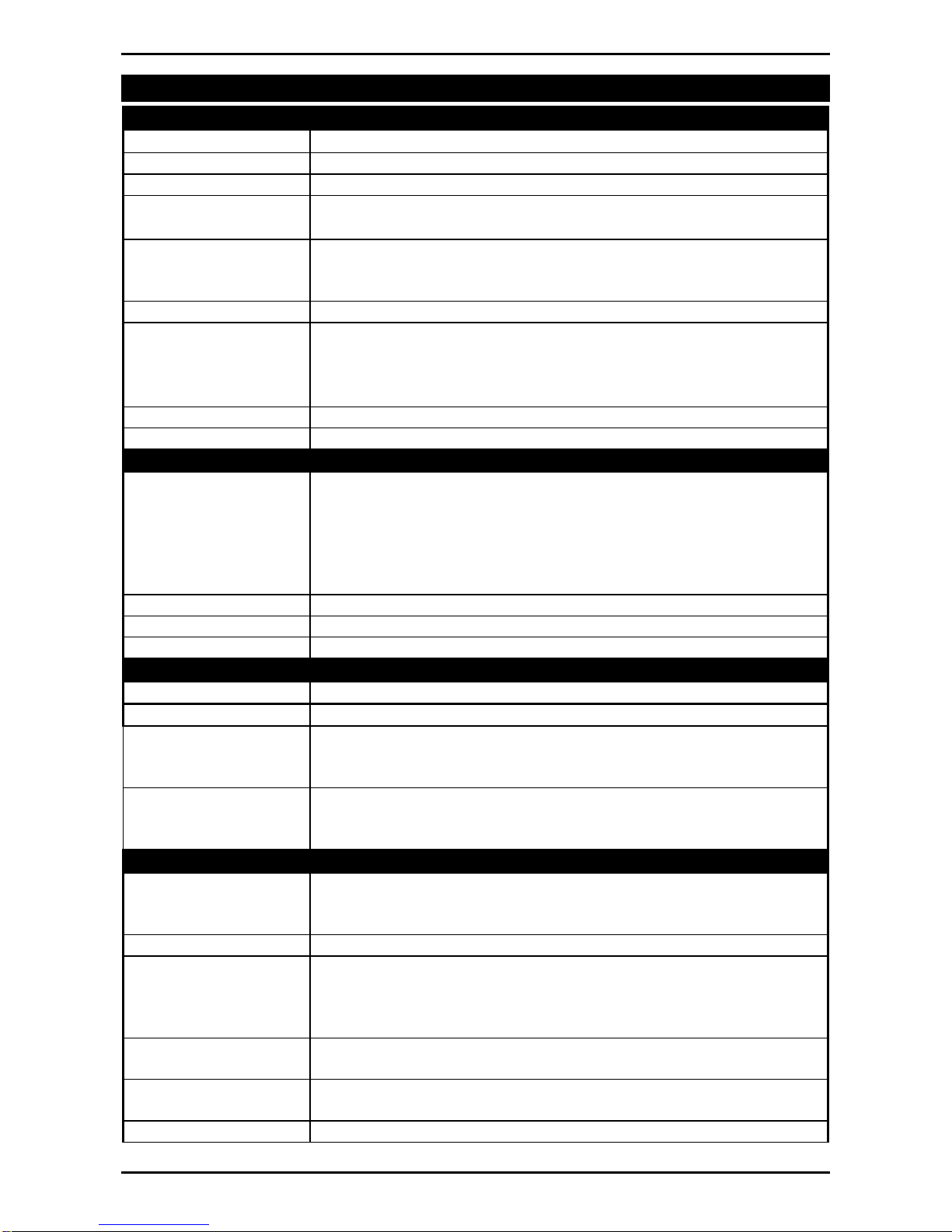

14.1.1.DATE.F (Date format) ................................................................................. 85

14.1.2.PCODE (Security passcodes) ..................................................................... 85

14.1.3.KEY.LOC (Key Function Access Control) ................................................... 86

14.1.4.DISP (Display options) ................................................................................ 87

14.1.5.ID.NAME (ID name strings) ........................................................................ 87

14.1.6.POWER (Power options) ............................................................................ 88

14.1.7.STR.EDT (String editor default mode) ........................................................ 88

14.1.8.USR.DEF (Set all non-calibration settings to defaults) ............................... 88

14.2.H.WARE (Hardware Configuration & Test) ................................................................. 88

14.2.1.LC.HW ........................................................................................................ 88

14.2.2.SER1.HW, SER2.HW ................................................................................. 89

14.2.3.IO.HW ......................................................................................................... 90

14.2.4.ANL.HW ..................................................................................................... 91

14.2.5.DSD.HW ..................................................................................................... 91

14.2.6.ETH.HW ...................................................................................................... 91

14.2.7.ETH.DEF (Set the M4221 Ethernet module to defaults) ............................. 92

14.3.SCALE (Load cell options and calibration) .................................................................. 93

14.3.1.BUILD (Scale parameters) .......................................................................... 93

14.3.2.OPTION (Scale options) ............................................................................. 94

14.3.3.CAL (Scale calibration) ............................................................................... 95

14.3.4.QA (QA alarm) ............................................................................................ 95

14.4.FUNC (Special functions) ............................................................................................ 96

14.4.1.NUM (Number of special functions) ............................................................ 96

14.4.2.SFn: TYPE (Function Types) ...................................................................... 96

14.4.3.SFn: KEY (Function Key / Remote Input) ................................................... 96

14.4.4.SFn: PRINT (Printing Functions) ................................................................ 97

14.4.5.SFn: SINGLE (Single Serial Output Functions) .......................................... 97

14.4.6.SFn: BLANK (Blanking Functions) .............................................................. 97

14.4.7.SFn: START, SFn: PAUSE, SFn:ABORT, SFn PSE.ABT, ST.PS.AB, SFn:

SUSPND (Batching Functions) ................................................................................... 98

14.4.8.SFn: THUMB (Thumbwheel Product Selection) ......................................... 99

14.4.9.SFn: REM.KEY (Remote Key Functions) ................................................... 99

14.4.10.SFn: REPORT (Report Functions) : .......................................................... 100

14.5.SER.NET (Network communications) ....................................................................... 100

14.6.SER.AUT (Automatic transmit) ................................................................................. 101

14.6.1.NUM (Number of Automatic Transmissions) ............................................ 101

14.6.2.AUTO.n (Automatic Output Configuration) ............................................... 101

14.7.PRINT (Printouts) ...................................................................................................... 102

14.7.1.NUM (Number of printouts) ....................................................................... 102

14.7.2.HEADER (Print header) ............................................................................ 102

14.7.3.FOOTER (Print footer) .............................................................................. 102

14.7.4.PAGE (Print page options) ........................................................................ 103

14.7.5.SPACE (Print blank space options) .......................................................... 103

14.7.6.PRINT.n … (Printout options) ................................................................... 104

14.8.SETP (Setpoints) ...................................................................................................... 105

14.8.1.NUM (Number of setpoints) ...................................................................... 105

14.8.2.SETP1 … SETP8 (Setpoint options) ........................................................ 105

14.9.BATCH ...................................................................................................................... 108

14.9.1.APP (Applications) (K411 and K412 only) ................................................ 108

14.9.2.GEN (General) .......................................................................................... 109