Reference Manual V1.00 SoftwareVersions3.xx

Page2 003R-677-210

5.6. ZERO Key................................................................................................................ 22

5.7. TARE Key................................................................................................................ 22

5.8. GROSS/NETKey..................................................................................................... 23

5.9. PRINTKey............................................................................................................... 23

5.10. FUNCTIONKey....................................................................................................... 23

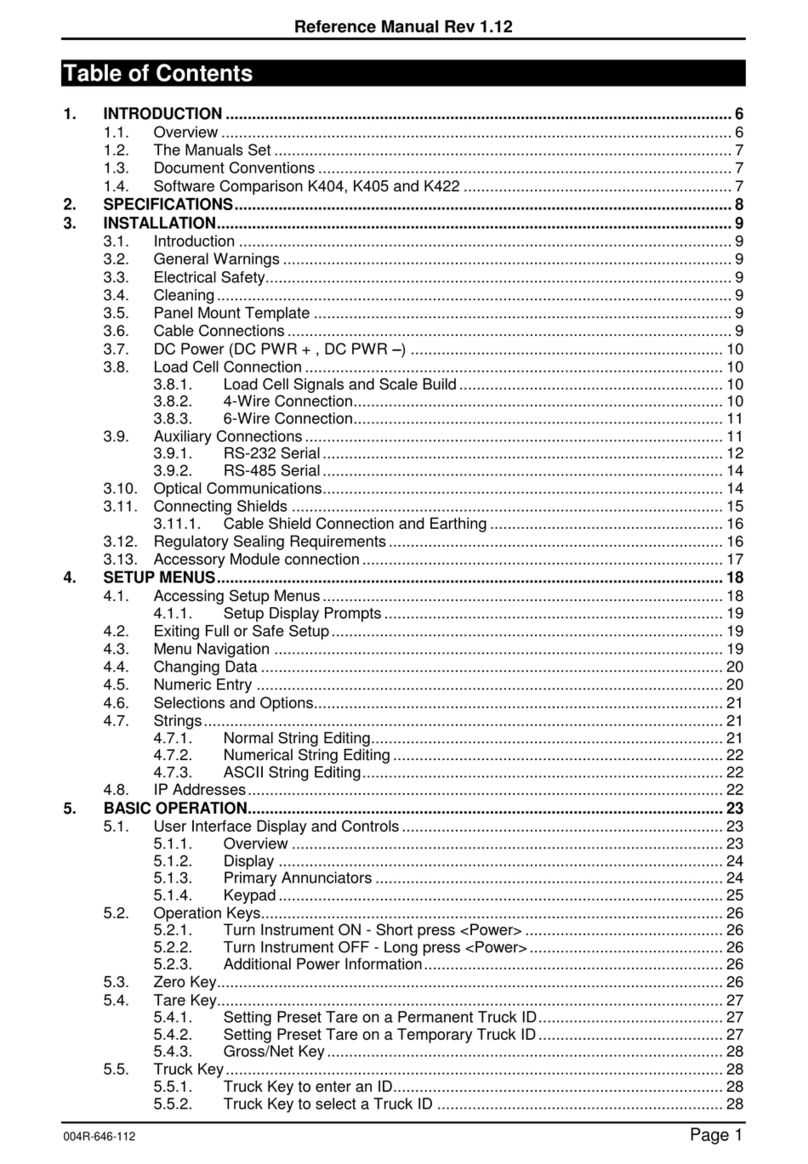

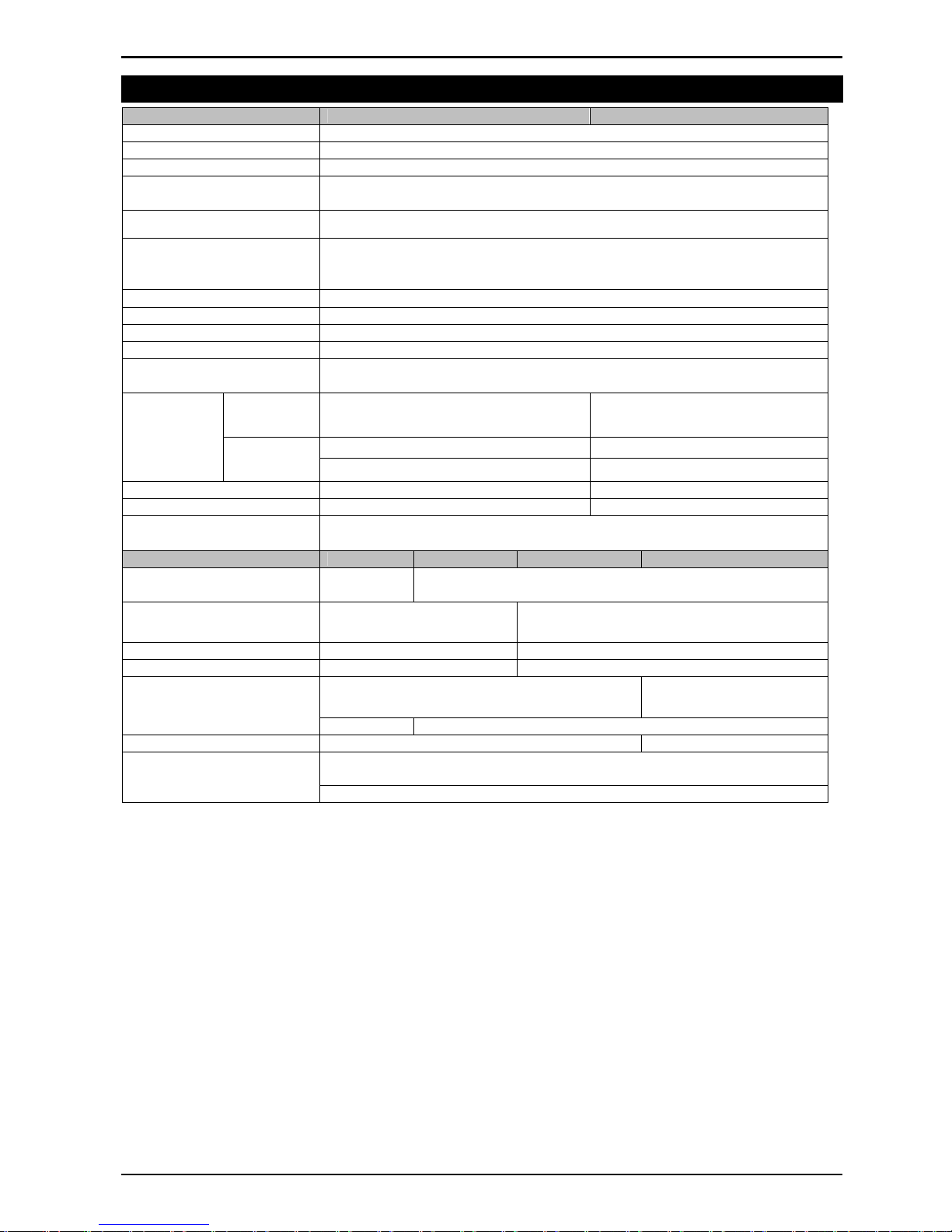

6. CONFIGURATION.............................................................................................................. 24

6.1. GeneralSetup Information....................................................................................... 24

6.2. BasicWeighingTerminology.................................................................................... 24

6.3. FilteringTechniques................................................................................................. 25

6.4. IndustrialvsOIMLand NTEP Modes ...................................................................... 25

6.5. Calibration Counter.................................................................................................. 25

6.6. Passcodes ............................................................................................................... 26

6.6.1. Full Setup Passcode ................................................................................ 26

6.6.2. SafeSetup Passcode............................................................................... 26

6.6.3. Setup Lock-Out........................................................................................ 26

7. CALIBRATION.................................................................................................................... 28

7.1. PerformingaDigitalCalibration withTest Weights................................................... 28

7.1.1. ZERO (ZeroCalibration Routine)............................................................. 29

7.1.2. SPAN (Span Calibration Routine)............................................................. 29

7.2. PerformingaCalibration withDirect mV/VEntry...................................................... 29

7.2.1. DIR.ZER(Direct ZeroCalibration Entry)................................................... 29

7.2.2. DIR.SPN (Direct Span Calibration Entry).................................................. 29

8. SETUP ................................................................................................................................ 30

8.1. AccessingSetup ...................................................................................................... 30

8.1.1. Access usingFull Setup........................................................................... 30

8.1.2. Access usingSafeSetup ......................................................................... 30

8.1.3. Setup DisplayPrompts............................................................................. 31

8.2. ExitingFull or SafeSetup......................................................................................... 31

8.3. Groups and Items.................................................................................................... 31

8.4. Setup Menus............................................................................................................ 32

8.4.1. BUILD(ScaleBuild)................................................................................. 32

8.4.2. OPTION(ScaleOptions).......................................................................... 33

8.4.3. CAL(ScaleCalibration)............................................................................ 34

8.4.4. SPEC (SpecialSettingsMenu)................................................................. 34

8.4.5. CLOC(Clock) –K35*............................................................................... 37

8.4.6. TEST(SpecialTest Functions)................................................................. 37

8.4.7. FACTRY (FactoryAdjustment Menu)....................................................... 38

8.4.8. –End –(LeavingSetup)........................................................................... 38

9. SERIALOUTPUTS(K344, K35*)........................................................................................ 39

9.1. SerialOutput Types ................................................................................................. 39