2 | Page

Table of Contents

1.1 SAFETY AND WARNING INFORMATION ........................3

1.2 TOOLS REQUIRED...................................................4

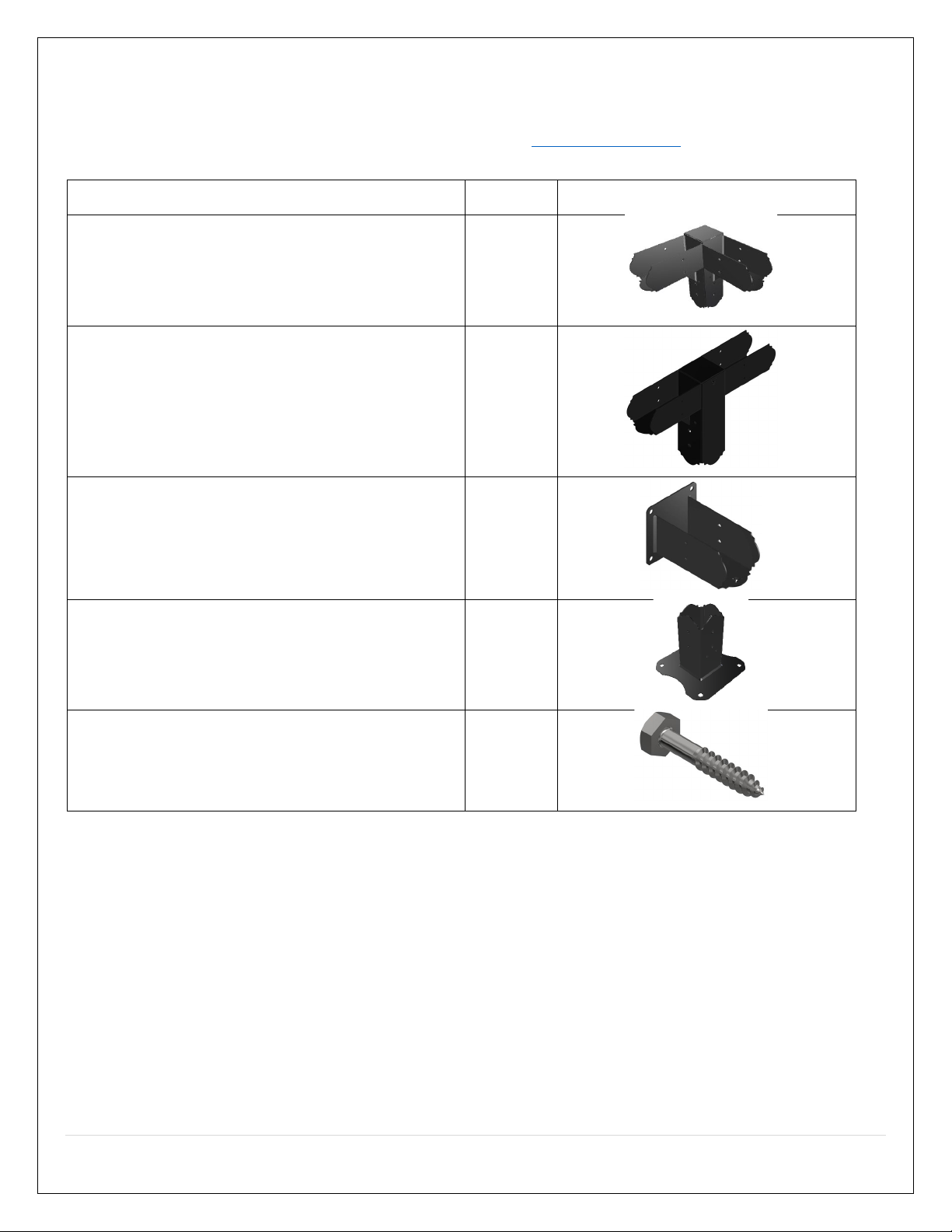

1.3 CONTENTS OF KIT #6S-WDC....................................5

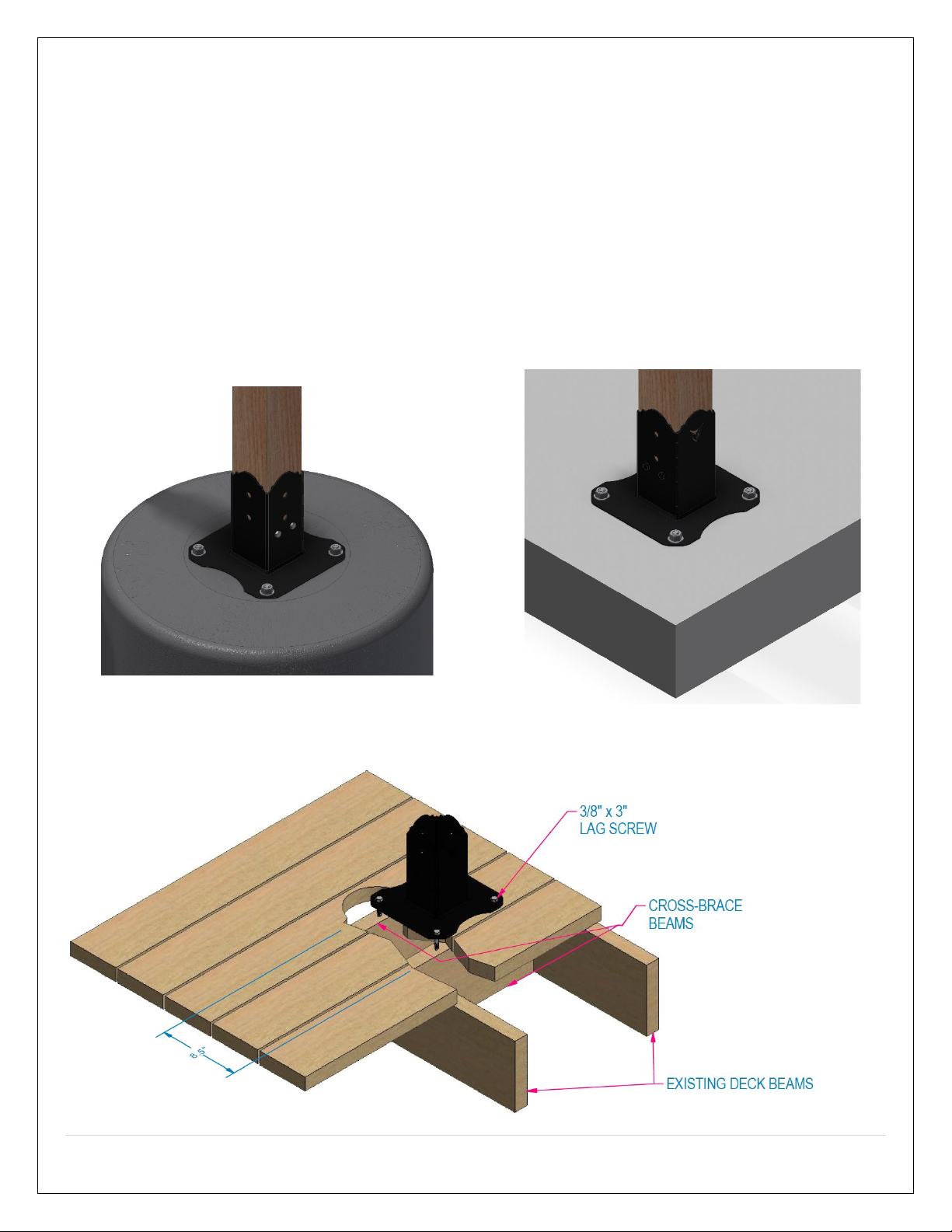

1.4 LIST OF MATERIALS THAT YOU WILL SUPPLY ..................6

1.5 SURFACE MOUNT SYSTEM........................................7

1.6 FLOOR ANCHOR BRACKETS INSTALLATION.................. 11

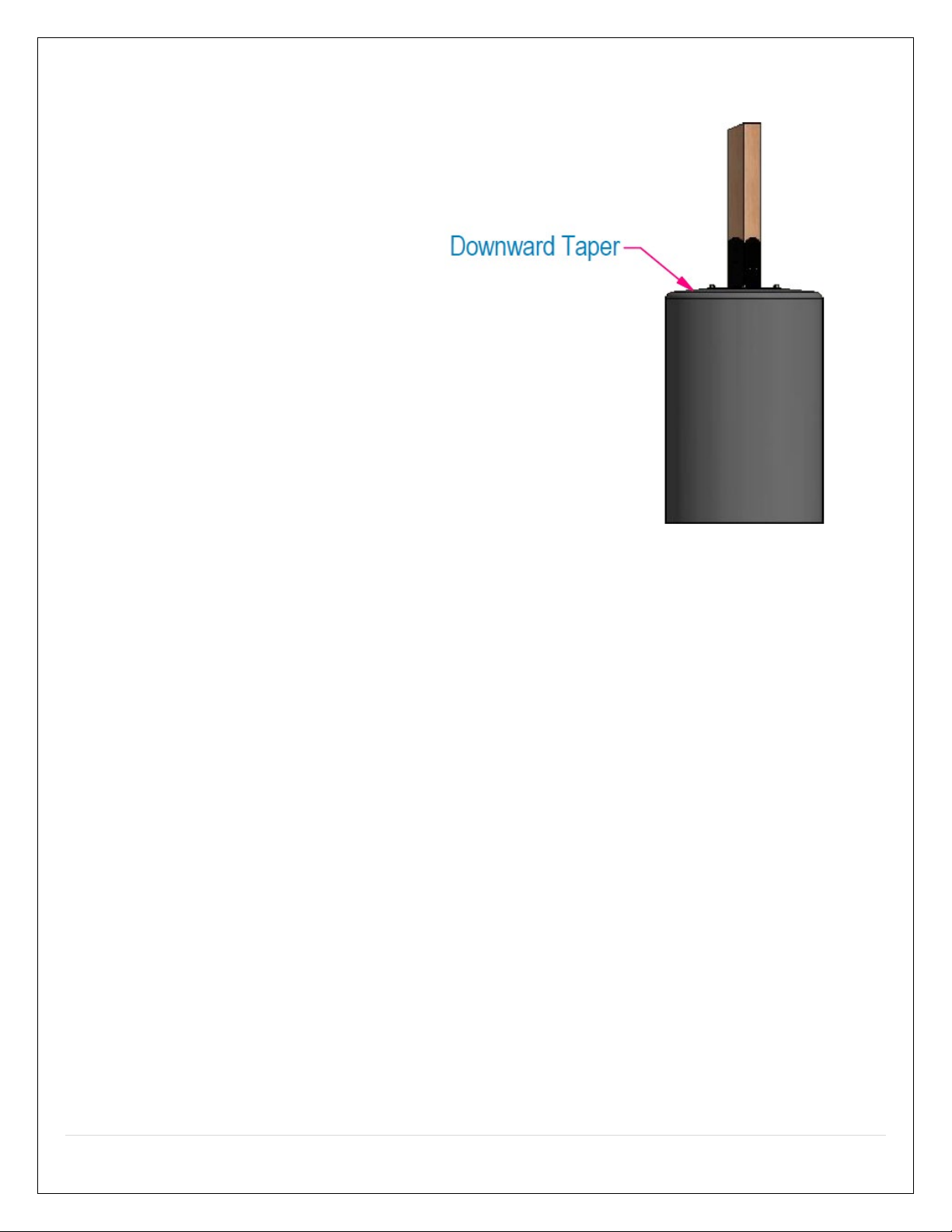

1.7 INSTALLING PERGOLA POSTS.................................. 13

1.8 POST-TOP BRACKETS INSTALLATION ........................ 15

1.9 POST TOP 2-WAY EXTENSION BRACKET INSTALLATION 18

1.10 6X6HEADERS INSTALLATION ................................. 20

1.11 WALL MOUNT BRACKET AND HEADERS INSTALLATION .. 22

2.1 CONDITIONS ...................................................... 26

2.2 EXCLUSIONS....................................................... 26

2.3 LIMITATIONS OF LIABILITY ..................................... 27

2.4 HOW TO OBTAIN WARRANTY SERVICE ..................... 27

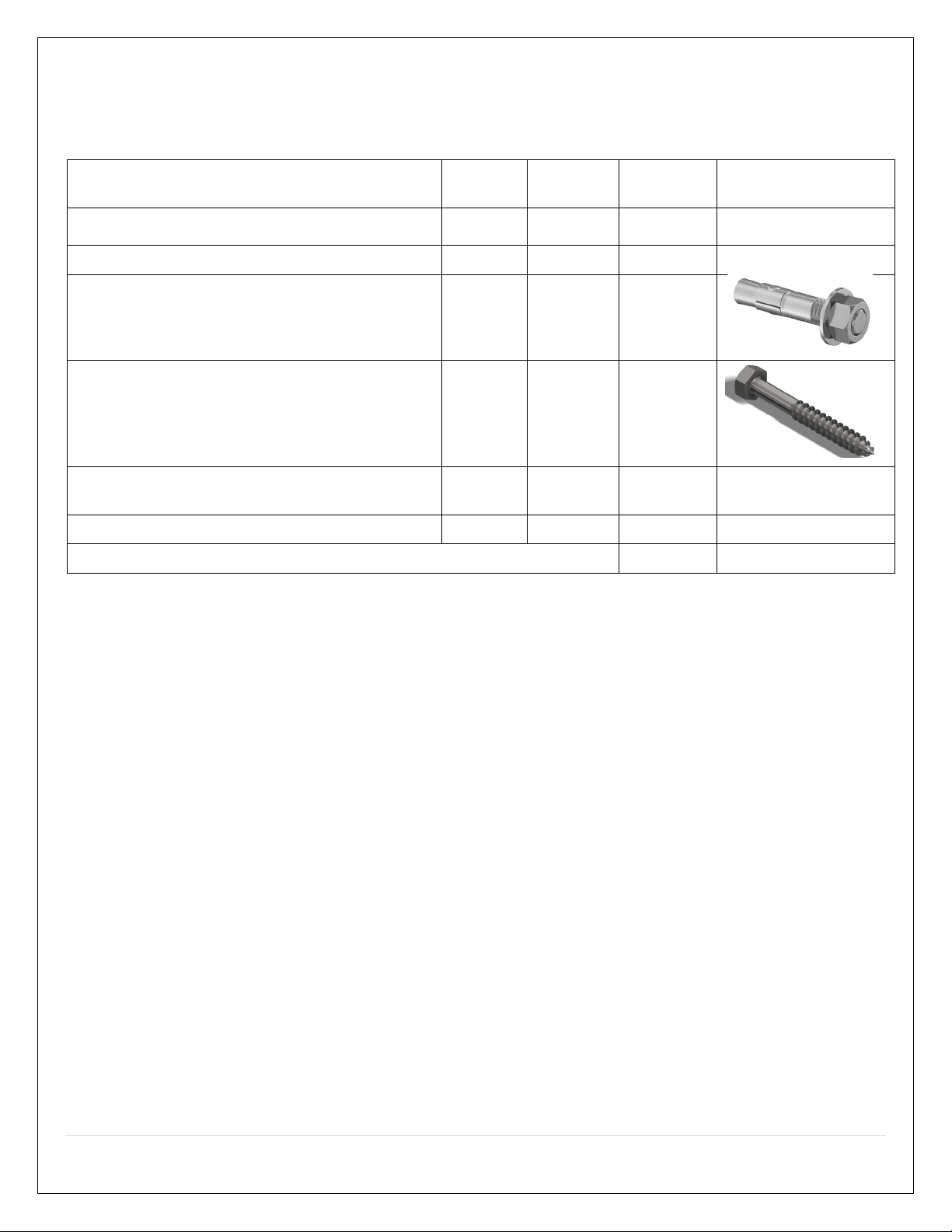

Proper pilot hole diameter and hole depth for various lag screws and wood types

Pilot hole drill diameter and hole depth

¼” X 1-1/4” Lag Screw

McMasterCarr.com SKU 92351A546

Soft Wood 3/32” drill bit diam., 1-1/4” depth

Hard Wood 3/16” drill bit diam., 1-1/4” depth

3/8” X 3” Lag Screw

McMasterCarr.com SKU 92351A636

Soft Wood 11/64” drill bit diam., 3” depth

Hard Wood ¼” drill bit diam., 3” depth

A properly sized pilot hole must be drilled before you attempt to drive lag screws into any pergola lumber member.

See Table, below. Driving lag screws into lumber, without first drilling a pilot hole, can prevent the lag screw from

driving fully into the wood or can lead to crack formation while driving the lag screw in, or later, as the wood dries

naturally. This can result in a weakened pergola structure.