RISO Inc. Technical Services & Support

US.RISO.COM

[ 2 - 4 ]

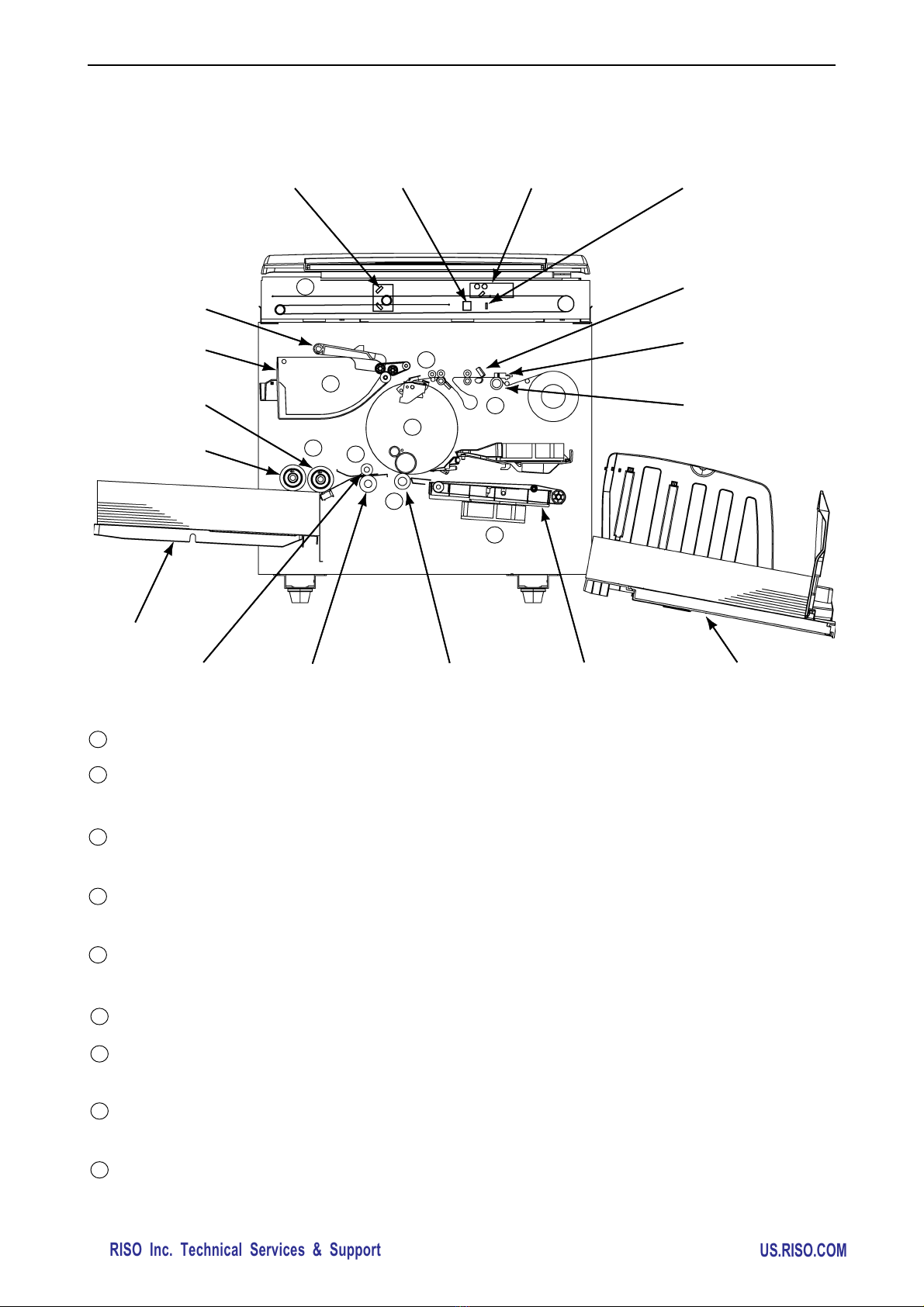

CHAPTER 2: MACHINE SUMMARY

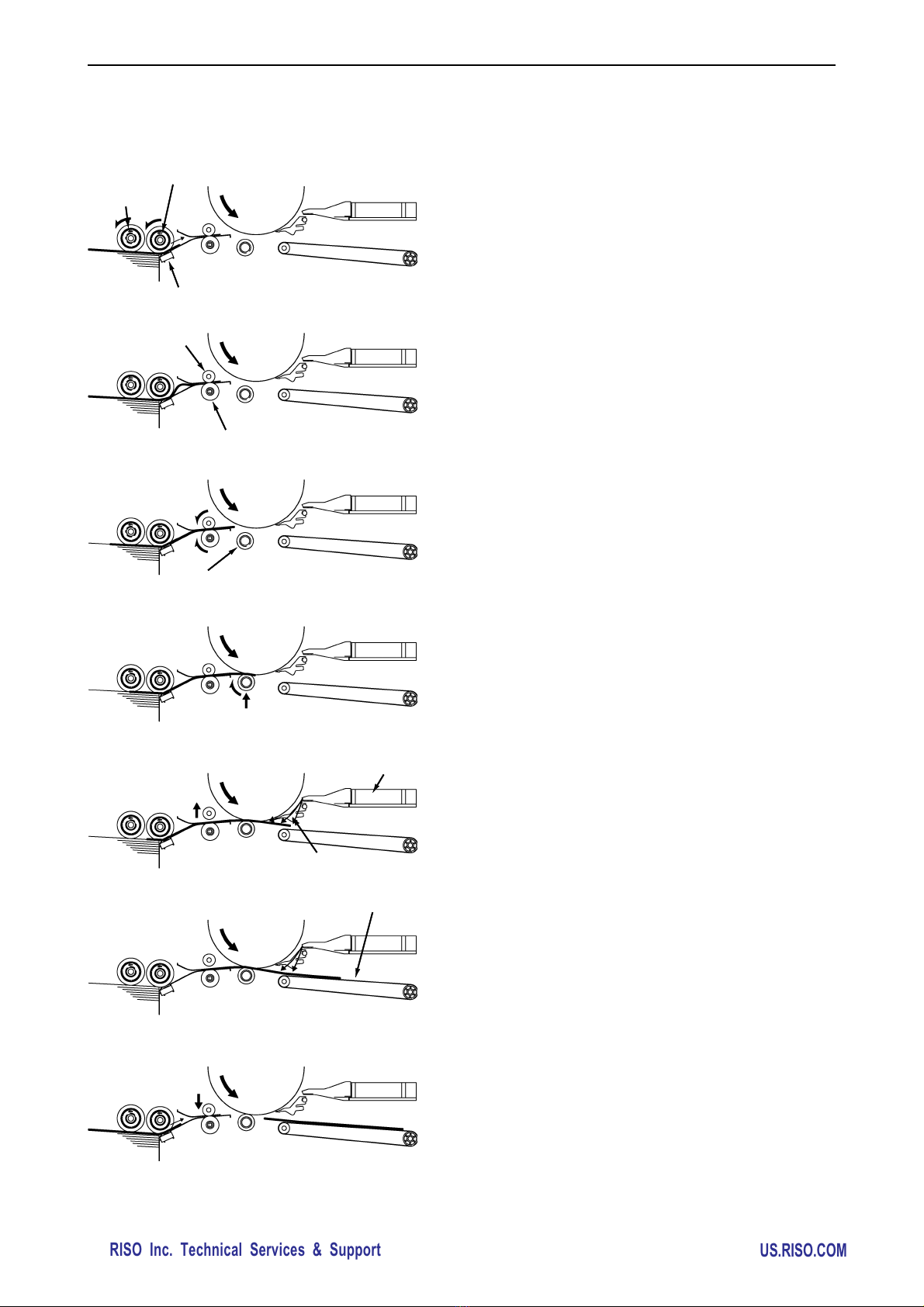

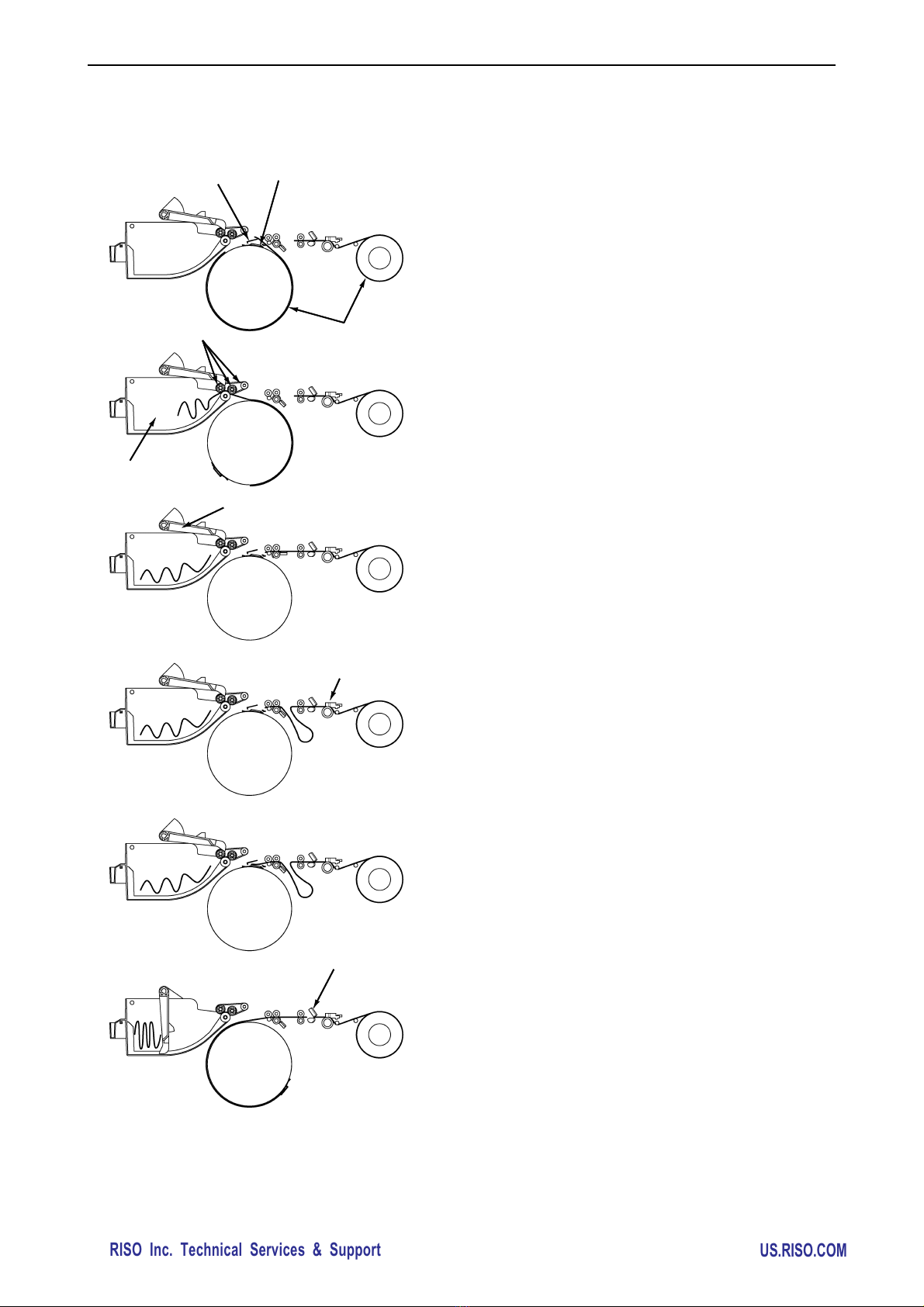

(1) When the print drum rotates, the scraper roller and

pickup roller also turn to feed paper. The stripper pad

allows only one sheet to pass through to the second

paper-feed area.

(2) The paper sent from the first paper-feed area contacts

the timing roller and guide roller, and stops temporarily.

This causes slight buckling of the paper.

(3) The timing roller and guide roller start rotating, feeding

paper to the pressure section. (This operation is referred

to as the “second paper-feed”. To prevent tension from

being placed on the end of the paper, the scraper roller

and pickup roller are free to spin.)

(4) When the paper is fed further in from the second paper-

feed area, the pressure roller rises to clamp the paper

between the drum and pressure roller to start the printing

operation.

(5) The printed paper is removed from the print drum by the

separator and separation fan. When the pressure roller

rises, the guide roller also moves up to prevent tension

from being placed on the tailing end of the paper.

(6) Then, the suction fan sucks in the air to keep the paper

firmly on the transfer belts while the paper is carried to

the paper-receiving tray.

(7) The next sheet of paper is sent to the first paper-feed

area, and the guide roller lowers.

3. Outline of Paper-feeding, Printing, and Paper-ejection Operations

Scraper roller

Pickup roller

Stripper pad

Guide roller

Timing roller

Pressure roller

Separation fan

Separator

Transfer belt

0202