BARRIER®GLIDER Single Slide Model 7100

2PUB. NO. 7100SSG FEBRUARY 2008

PRODUCT INTRODUCTION

TABLE OF CONTENTS

INSTALLATION INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . .3

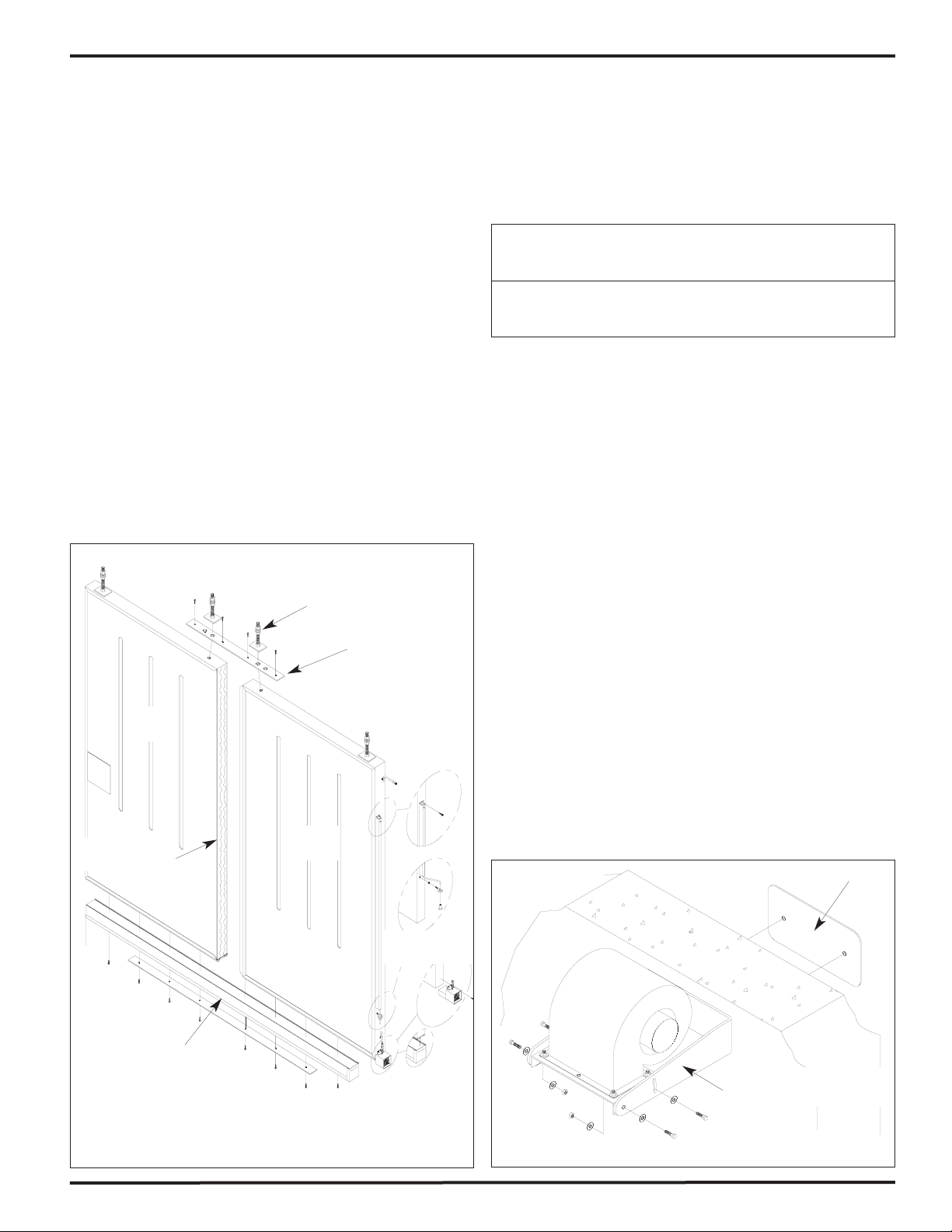

HEADER INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

PERIMETER SEAL INSTALLATION . . . . . . . . . . . . . . . . . . . .6

RETENTION SYSTEM INSTALLATION . . . . . . . . . . . . . . . . .7

PANEL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

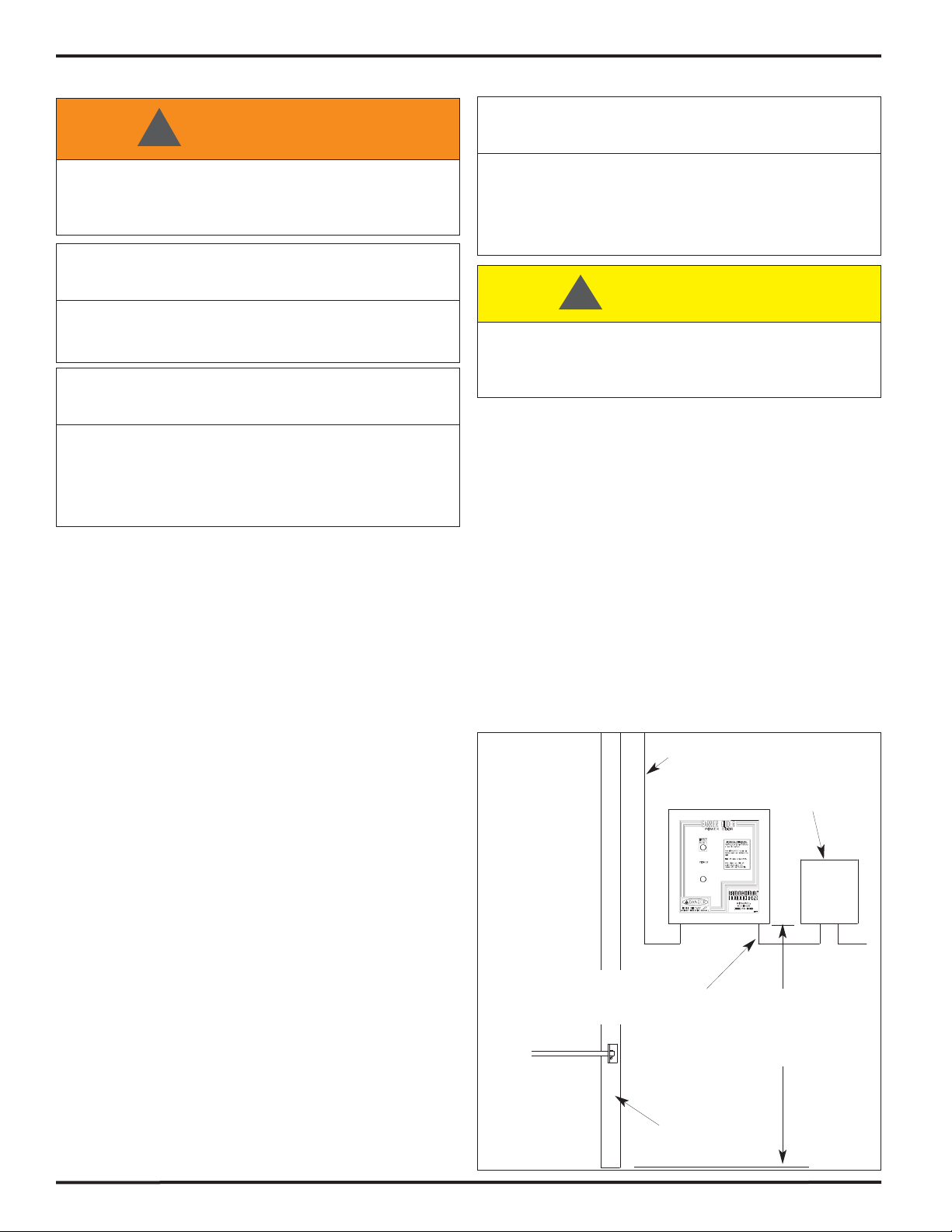

ELECTRICAL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . .10

INPUT / OUTPUT CHART . . . . . . . . . . . . . . . . . . . . . . . . . . .12

TROUBLESHOOTING / MAINTENANCE . . . . . . . . . . . . . . .13

FINAL CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

ARCHITECTURAL DRAWING . . . . . . . . . . . . . . . . . . . . . . . .19

NOTICE TO USER

Our mission is to “Improve Industrial Safety, Security and

Productivity Worldwide Through Quality and Innovation.”

Thank you for purchasing the BARRIER®GLIDER from RITE-

HITE DOORS, INC. The BARRIER GLIDER is designed to be a

fast, smooth opening, low maintenance door that provides

superior environmental separation while reducing passage time

and temperature loss.

This manual should be thoroughly read and understood before

beginning the installation, operation or servicing of this door.

Complete Final Checklist prior to leaving site.

Refer to partslist manual for exploded views and part numbers.

This owners manual MUST be stored near the door.

RITE-HITE DOORS, INC. reserves the right to modify the

electrical and architectural drawings in this manual as well as

the actual parts used on this product are subject to

manufacturing changes and may be different than shown in this

manual. Due to unique circumstances with varying

requirements, separate prints may be included with the unit.

The information contained in this manual will allow you to

operate and maintain the door in a manner which will insure

maximum life and trouble free operation. The serial # for your

door is on a label located on the side of the control box and

support post.

Your local RITE-HITE DOORS, INC. Representative provides

the Planned Maintenance Program (P.M.P.) which can be fitted

to your specific operation. If any procedures for the installation,

operation or maintenance of the BARRIER GLIDER have been

left out of this manual or are not complete, contact RITE-HITE

DOORS, INC. Technical Support at 1-563-589-2722.

RITE-HITE DOORS, INC. are covered by one or more of the

following U.S. patents, including patents applied for, pending, or

issued: 5,025,846, 5,143,137, 5,203,175, 5,329,781, 5,353,859,

5,392,836, 5,450,890, 5,542,463, 5,579,820, 5,601,134,

5,638,883, 5,655,591, 5,730,197, 5,743,317, 5,794,678,

5,887,385, 5,915,448, 5,944,086, 5,957,187, 6,042,158,

6,089,305, 6,098,695, 6,145,571, 6,148,897, 6,192,960,

6,321,822, 6,325,195, 6,330,763, 6,352,097, 6,360,487,

6,574,832, 6,598,648, 6,612,357, 6,615,898, 6,659,158

SPECIAL FEATURES

• i-COMM™ Universal Controller

• Energy Efficient Design Featuring High R-Value Panels

• Flexible or High Security Fiberglass Panels

• Unique Thermal Air Sealing System

• Impactable Panel Retention System

• Universal Drive Side

RECOMMENDED SERVICE PARTS

Bottom Seal Panel Blower/Heater

Retention Cord Limit Switch

Fuses

INSTALLATION TOOLS REQUIRED

Fork and Scissors Lift

12’ Step Ladder

25’ Tape Measure

6’ Carpenters Level

Hydro Level

Cordless Drill

Wire Strippers

Utility Knife

Hammer

1/2” Masonry and/or Drill Bit for thru bolting

7/16”, 1/2”, 9/16” Open End and/or Socket Wrench

(2) 15/16” Open End Wrenches

11/16” x 12” Drill Bit for thru bolting

Straight Screwdriver (small 1/8” spade)

Hardware for mounting the header, support posts, retention rod,

blower and perimeter seals to wall are provided. Caulk for

perimeter seals is not provided.

WARRANTY

RITE-HITE DOORS, INC. warrants that it’s BARRIER®GLIDER

door will be free from defects in design, materials, and

workmanship for 150,000 cycles or for a period of one (1) year

from the date of shipment. The panel fabric warranty covers

material failure under normal wear conditions; it does not cover

labor or damage incurred from abuse, misuse or impact.

Warranty does not cover wear items such as seals, belts, fuses,

and bulbs. All claims for breach of this warranty must be made

within thirty (30) days after the defect is or can, with reasonable

care, be discovered. To be entitled to the benefits of this

warranty, the products must have been properly installed,

maintained, operated within their rated capacities, and not

otherwise abused. Periodic lubrication and adjustment are the

sole responsibility of the owner. This is RITE-HITE DOORS,

INC. exclusive warranty. RITE-HITE DOORS, INC. expressly

disclaims all implied warranties of merchantability and fitness.

Non-standard RITE-HITE DOORS, INC. warranties, if any, must

be specified by RITE-HITE DOORS, INC. in writing.

In the event of any defects covered by this warranty, RITE-HITE

DOORS, INC. will remedy such defects by repairing or

replacing any defective equipment or parts, bearing all of the

costs for parts, labor, and transportation. This shall be the

exclusive remedy for all claims whether based on contract

negligence or strict liability. Neither RITE-HITE DOORS, INC.,

RITE-HITE DOORS, INC. representatives or any other

manufacturer whose products are the subject of this

transaction, shall in any event be liable for any loss or use of

any equipment or incidental or consequential damages of any

kind whether for breach of warranty, negligence, or strict liability.

The application of a manufacturer's specifications to a particular

job is the responsibility of the purchaser.

RITE-HITE DOORS, INC.

8900 N. Arbon Drive

P.O. Box 245020

Milwaukee, Wisconsin 53224-9520

Sales: 414-355-2600

Toll Free: 800-456-0600

Aftermarket: 563-589-2781

Service: 563-589-2722

Service Fax: 563-589-2737

Representatives in All Major Cities

www.ritehite.com