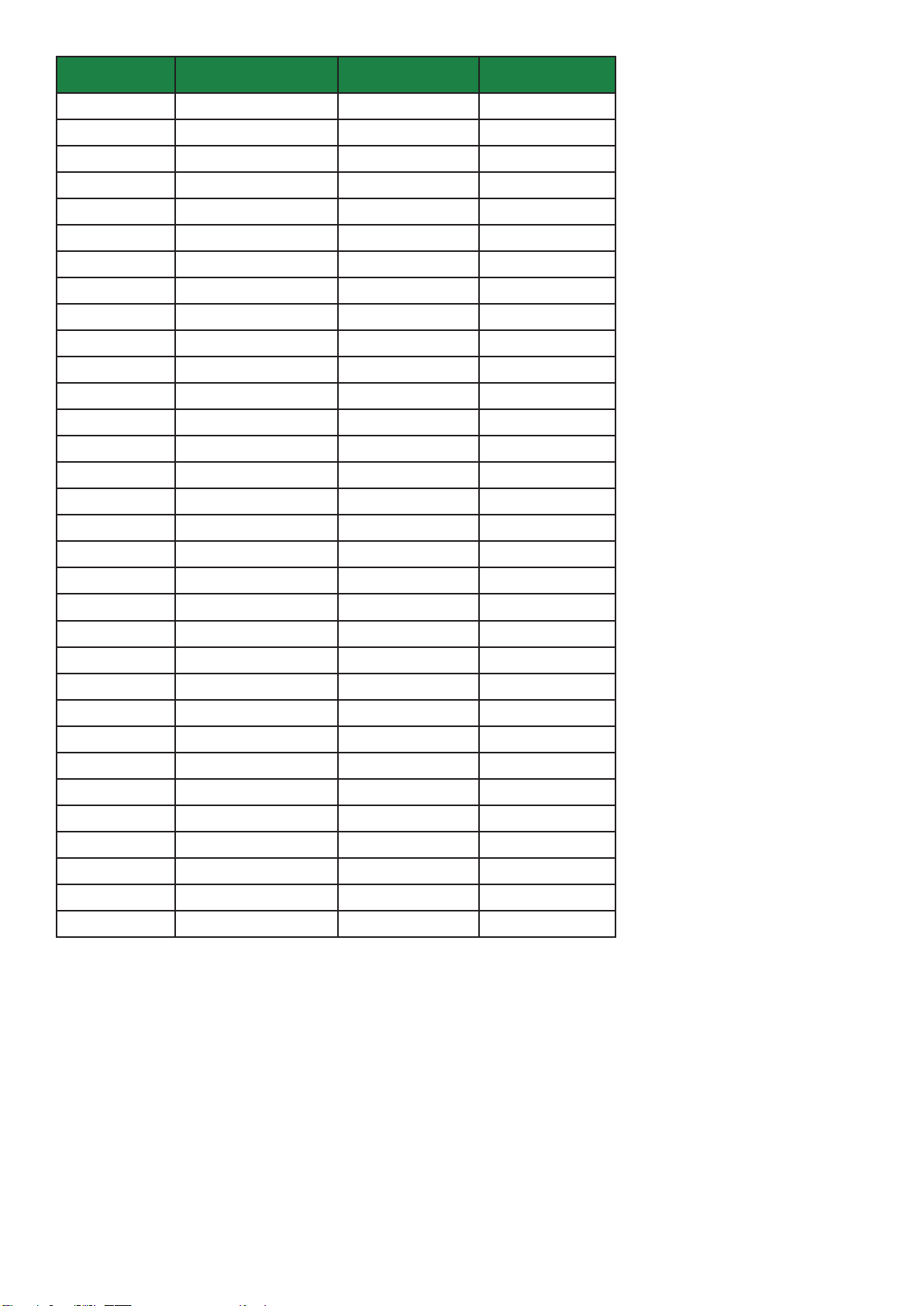

Version Product

catego-

ries

Connection

overpressu-

res [mbar]

Used gas Country of destination

A1 I2E 20 G20 DE, NL, PL, RO

I2ELL 20, 20 G20, G25 DE

I2E+ 20/25 G20/G25 BE, FR

I2H 20 G20 AT, BG, CH, CZ, DK, HR, EE, ES, FI, GB, GR, IE, IT,

LT, LV, NO, PT, RO, SE, SI, SK, TR, LU, CY, FR

I3B/P 30 G30 BG, CY, CZ, DK, GB, HR, EE, FI, FR, GR, HU, IT, LT,

LV, MT, NL, NO, RO, SE, SI, SK, TR

I3B/P 50 G30 AT, DE, CZ, CH, FR, SK

I3P 37 G31 BE, CH, CZ, ES, GB, GR, IE, RO, SI, SK, FR, NL,

PT, HR, IT, LT, PL, TR

I3+ 28-30/37 G30/G31 BE, CH, CY, CZ, EE, ES, FR, GB, GR, IE, IT, LT, PT,

SI, SK, TR

II2E3B/P 20, 50 G20, G30 DE, PL, RO

II2ELL-

3B/P

20, 20, 50 G20, G25, G30 DE

II2E+3+ 20/25, 28-

30/37

G20/G25, G30/

G31

BE, FR

II2H3B/P 20, 30 G20, G30 BG, CZ, GB, DK, HR, EE, FI, GR, IT, LT, LV, NO, RO,

SE, SI, SK, TR, CY, FR

II2H3B/P 20, 50 G20, G30 AT, CH, CZ, FR, SK

II2H3P 20, 37 G20, G31 CH, CZ, ES, GB, GR, IE, RO, SI, SK

II2H3+ 20, 28-30/37 G20, G30/G31 CH, CY, CZ, EE, ES, GB, GR, IE, IT, LT, PT, SK, SI,

TR

Table of gases for which the product is intended

6