RMS caddy User manual

Thompson House

Unit 10 Styles Close, Sittingbourne, Kent, ME10 3BF

Tel: 01795 477280 Fax: 01795 229692

E-mail address: sales@rms-kent.co.uk

www.ineedawheelchair.co.uk

The

Manufactured

by

Seating System

The

Seating System

Installation and User Manual

EDITION 3 May. 2017

INTRODUCTION

RMS Ltd would like to take this opportunity of thanking you for choosing a

caddy Seating System. We are confident that it will meet with the necessary

seating requirements of the user for which it was prescribed.

From the time of its initial conception, the caddy Seating System has undergone

rigorous strength testing and quality inspections, including successful “Crash

Testing” to ISO 16840-4 standard using a 50Kg ATD.

In view of the wide range of wheelchairs into which the caddy Seating System

can be interfaced, the pictures in this manual may not depict identically the

components supplied, or the location positions of installation for your specific

application. They are intended however, for general guidance purposes only and

to assist a suitably qualified person to install and adjust a complete caddy

Seating System.

RMS Ltd reserves the right to change, without notice, the design, methods of

manufacture, or any materials used in the construction of the caddy Seating

System, where it considers such changes will serve to improve the product

quality, or become necessary to meet any changes in device legislation.

Should the reader have any concerns regarding the installation, set-up,

adjustment, or use of the caddy Seating System, please contact the RMS Ltd.

Technical Help-Line on 01795-477280.

CONTENTS Page

Introduction 2

Safety Guidelines 3

Component Identification 4

Initial Installation:- 5

Seat and Backrest Identification (Positive Locking style) 6

Seat and Backrest Identification (Standard style) 7

Seat Base Installation (Using lock & Latch interfacing) 8

Installing Lock & Latch 8/9

Seat Base Installation (Fixed/Bolt-on Interface) 10/11

Backrest Installation (Positive Locking style) 12/13

Backrest Installation (Standard style) 13

Backrest Remove/Refitting and Angle Adjustment 14

Backrest Height Adjustment 15

Pelvic Supports 15 and 19

Lateral Thoracic Supports 16

Accessory Tricep Pads and Shoulder Pads 17

Accessory Headrest and Mounting 18

Alternative Pelvic Supports and Accessory Knee Adductors 19

Accessory Leg Abductor (Pommel) 20

Upholstery Care and Maintenance 21

Transportation 22-24

Warranty Statement 25

General Information, Product Maintenance and

Inspection Record 26

2

27

USER / CARER NOTES

26

GENERAL INFORMATION

Your caddy Seat Base serial Number is: …………………….........…

Your caddy Backrest serial number is: ……...…………..........……

Date of Supply: ………………..........………

Supplied to: …………………………………………………….....….…….

…………………………………………………….....………….

.………………………………………………………......………

PRODUCT MAINTENANCE

For safety reasons, the manufacturer recommends that components such as

the Seat Base Brackets, Lock and Latch Interface Brackets, Backrest

Mounting Brackets, Headrest Mountings, Pelvic Support Mountings, Thoracic

Support Mountings, Abductor and Adductor Mountings are checked for security at

annual intervals. Inspection frequency should be increased accordingly for heavy

users.

Any defects should be reported to the appropriate authority, with any repairs

being carried out using genuine original equipment replacement parts, available

direct from RMS Ltd.

(Also refer to Upholstery Maintenance section on pages 21).

INSPECTION RECORD

DATE INSPECTED

BY

COMMENTS SIGNED

3

SAFETY GUIDELINES

Due to the various activities that a wheelchair user has to perform, RMS

recommends that, prior to issuing the caddy Seating System and the

wheelchair into which it is to be interfaced, this manual, together with any

wheelchair manufacturer’ User Guide, should be studied by all relevant

persons to ensure that all instructions, procedures and warnings are

carefully observed and understood.

Prior to commencing the installation of a caddy Seating System, the

surrogate wheelbase should be placed on a level non-slip surface with the

parking brakes applied.

For correct support and user comfort, it is strongly recommended that the

initial installation and adjustments are carried out by a suitably qualified

person.

The maximum occupant capacity of a complete caddy Seating System for

transportation purposes, when interfaced into a suitably tested wheelchair

with a seat width up to 17", is 50Kg.

As the installation of a caddy Seating System may raise or position the user

further forward in their wheelchair, an appropriate stability test should be

carried out prior to final commissioning.

After the caddy Seating System has been initially adjusted to suit the

individual user, any settings should not be subsequently affected by the

removal and refitting of the Seat Base or Backrest to allow the wheelchair to

be folded. However, care should be taken not to impact adjustable

components whilst the Seat Base or Backrest is removed from the wheelchair

as this could affect their original pre-set position.

To accommodate any changes in user growth or postural positioning, it is

recommended that the user be checked at regular intervals by a suitably

qualified person, to ensure that adjustable components are correctly set to

suit the user’s current requirements.

Carers should ensure correct utilisation of any positioning Straps or

Harnesses, as failure to do so could result in injury to the user. It is

recommended that any postural Straps or Harnesses being used, are the first

items to be secured when the user enters the seat and the last items to be

released before exiting.

Worn or damaged upholstery can lead to hygiene contamination, cause

injury to the user and, in some cases, fail to support the user correctly.

Regular inspections of all upholstery should be made and any defects should

be reported to the relevant authority for rectification as soon as possible.

Ancillary devices, such as the Headrest, positioning Straps and Harnesses,

Knee-block or Pommel should be checked for security on a daily basis.

The wheelchair parking brakes should always be applied before attempting to

transfer the occupant, removing or refitting the caddy Seating System or

making any adjustments.

Never hang heavy objects on the caddy Seating System or any part of the

wheelchair, as this could seriously affect the overall stability.

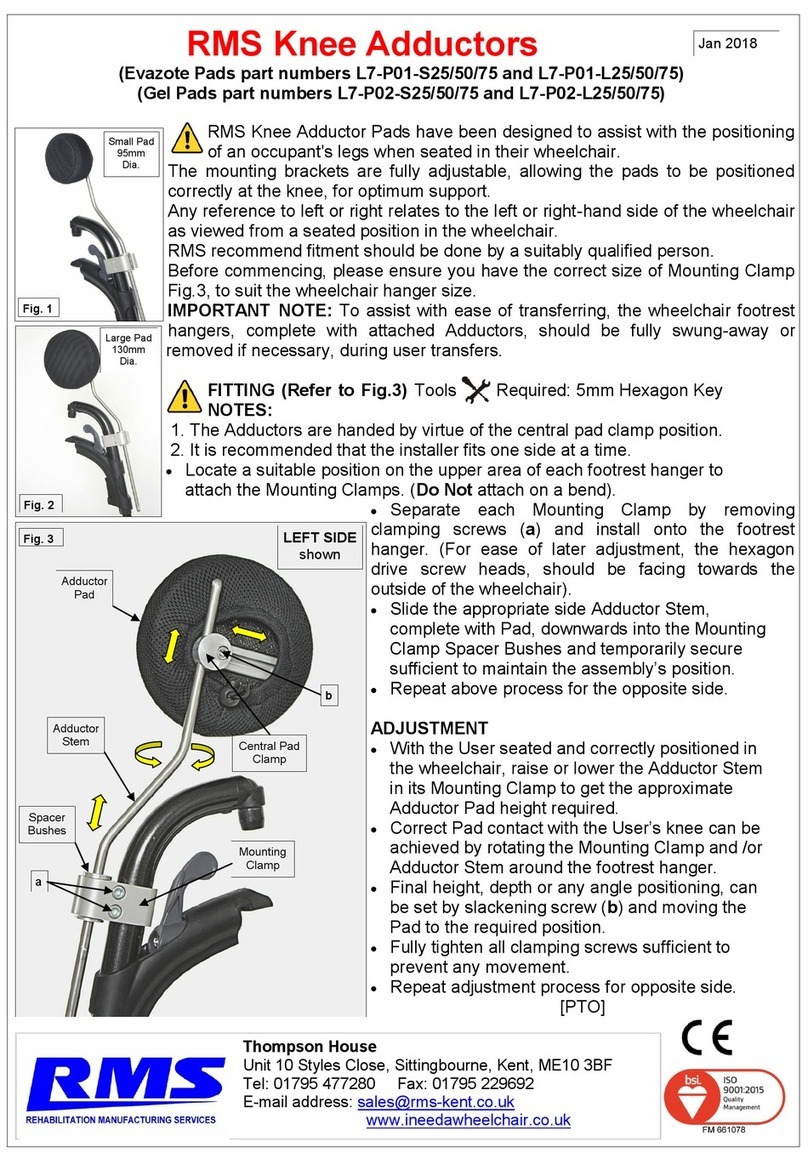

The caddy Seating System —Component Identification

4

RMS positive-locking

“Swing-Away”

Lateral Supports

with removable,

washable Covers

Lock & Latch

Interfacing

System

Width Adjustable

Pelvic Supports

with removable,

washable Covers

Multi-adjustable

Headrest

with removable,

washable Cover

Padded Backrest

Cushion

with removable,

washable Cover

Optional

Flat or Ramped

Cushion

with removable,

washable Cover

Sacral Pad

with removable,

washable Cover

Seat Depth

Adjustment

Panel

Fig. 1

WARRANTY STATEMENT

Every effort is made by RMS Ltd to ensure that your caddy Modular

Adjustable Seating System is manufactured to the highest standards and

supplied to the specifications as detailed on the prescription.

The supply of our quality products is backed by the company’s ISO 9001

–2015 Quality Management System and CE Marking declaration.

The caddy Modular Seating System is supplied with a manufacturer’s

warranty covering faulty materials or workmanship, for a period of twelve

months from the date of dispatch from our factory.

In the unlikely event of a warranty claim being necessary, the failed part

must be returned to the manufacturer, or the manufacturer’s approved

repairer, for inspection. The failed part may then be repaired or replaced at

the manufacturer’s discretion or that of their approved repairer.

In the latter case, any displaced parts must be returned to the manufacturer

for inspection.

Any part, component or accessory, repaired or replaced during the twelve

month warranty period, will continue to be covered for the balance of the

warranty period only.

As unusually high rates of wear on this device, or its ancillary parts, may be

caused by the user’s clinical condition, the manufacturer may consider this

to be beyond its control. Therefore, items such as Upholstery may only be

considered for repair or replacement under the terms of the product

warranty where a failure is clearly attributed to a manufacturing, material or

fabric defect.

With the exception of modifications and /or alterations carried out by the

manufacturer, to meet the clinical needs of the user, any attempt to change

the design or modify the construction of the caddy Modular Seating

System in any way, will invalidate the product warranty and the

manufacturer’s CE marking declaration.

For further assistance with any matters relating to the product warranty or product Technical

Information, please contact the RMS Ltd Technical Help-line on 01795-477280.

25

Occupant Restraint Considerations:

A prescription should specify the type of occupant restraint required in a vehicle,

i.e. a lap and diagonal belt or full harness. The amount of upper body control that

the user has during normal vehicle movement should be taken into account.

“Normal” movement includes, braking and cornering, which have considerable

effect on persons with limited upper trunk control.

Some wheelchair users for example, may be able to maintain an upright posture

when using the wheelchair indoors, but not whilst travelling in a motor vehicle.

Such considerations apply equally to lower limb amputees and users in

supportive seating units who may also have limited upper body control.

**********

Example pictures from the successful caddy testing to ISO 16840-4

PRE-TEST

POST TEST

24

5

INITIAL INSTALLATION

IMPORTANT NOTES:

The caddy Seating System is supplied assembled and ready to be

interfaced onto the intended surrogate wheelchair. However, the installer

should note that some adjustment of both Seat and Backrest Support

Brackets may be necessary to ensure correct interfacing.

The installer should also note that at the time of despatch from the RMS

factory, none of the Backrest or Seat Base Support Brackets have been

fully and finally tightened. This has been done to allow the installer ease

of correctly positioning the interface brackets to suit the intended

surrogate base.

It is therefore, the responsibility of the installer to ensure that all

Interface Mounting and Component Screws and Nuts are correctly

tightened, before handover to the user. (This does not apply to caddy

Seating Systems interfaced with a surrogate base at the RMS factory).

Where the caddy Seating System is supplied by RMS Ltd., together with a

surrogate wheelbase, the following installation instructions may not

apply, as the interfacing and mounting brackets will normally be pre-set at

the RMS factory prior to delivery. Adjustable components may also be pre

-set to the required specification, where the necessary information was

stated on the device prescription.

Before commencing installation, the surrogate wheelchair should be

vacated and placed on a suitable level non-slip surface, with the parking

brakes applied.

For ease of installation, both side-arms should be removed wherever

possible.

Any references to left or right, relate to positions as viewed from being

seated in the wheelchair facing forwards.

The basic weight of a “Standard Specification” caddy Seating System to

suit a 43cm (17”) seat width wheelchair is 11.5Kg (25.3lbs)

Table of contents

Other RMS Wheelchair manuals