RMS Gill 4 Seating System EDTION TWO 2012 User manual

The

New

Seating System

The Perfect Partnership

The Perfect Partnership

The Perfect Partnership

USER

MANUAL

EDTION TWO

2012

4

Discovery Edition

INTRODUCTION

The Gill 4 Seating System is the result of experienced, thoughtful design

and rigorous testing over 16 months of field trials, in-house testing and frontal

impact testing. The Gill 4 Seating System was successfully tested to ISO 16840-

4 at the Transport Research Laboratory in March 2012.

Many adjustable features have been built into the Gill 4, enabling it to

become an extremely versatile seating system, available in three sizes.

With two backrest options available, the Gill 4 Seating System has been

designed specifically by our engineers, to meet the known wide range of

demands placed on postural positioning seat units.

The “Dynamic” Backrest option, offers the ability to absorb the type of

thrusting forces, placed on it during user extensor spasms, with a uniquely

designed absorbing system, which is variable to suit individual user

requirements.

The “Fixed” Backrest option, offers the same supportive capabilities as a normal

rigid back seat unit, but with angle adjustment available to 90, 95 and 100

degrees.

RMS Ltd reserves the right to change without notice, the design, methods

of manufacture, or raw materials used in the construction of the Gill 4 Seating

System, where it considers such changes will serve to improve the product

quality, or become necessary to meet any changes in device legislation.

Should the reader have any concerns regarding the installation, set-up,

adjustments, or use of the Gill 4 Seating System, please contact the RMS Ltd

Technical Help-line on 01634-578881.

Contents

Gill 4 Seat Plan ....................................................... 3

Safety Guidelines ....................................................4

Initial Installation ..................................................... 5

Inserting Gill 4 into Discovery wheelbase .............. 6

Adjusting the Gill 4 Seating System ...................... 7

Seat Depth and Sidearms ..................................... 7

Sacral Support Panel and Pelvic Supports ........... 8

Thoracic Supports ................................................. 9

Headrest ................................................................10

Notes regarding Backrest adjusting ..................10-11

Footrests ............................................................... 11

Anklesures installation and use .............................12

Anti-thrust Seat depth adjustment .........................13

Abductor (Pommel) Install and Adjust ..............14-15

Upholstery and Cleaning .......................................16

Transportation information ................................17-20

Technical Data ..................................................20-21

Warranty Statement .............................................. 22

General Information .............................................. 23

Product Maintenance ............................................ 23

2

Both Fixed and Dynamic Seat Units are supplied as standard, with the following

features:-

Quick-release Interface.

Depth-adjustable Anti-thrust Seat Cushion.

Width adjustable full-length fixed Pelvic Supports.

Width adjustable swing-away Thoracic Supports.

Adjustable Sacral Support.

RMS type “D” Headrest.

RMS PB003 Pelvic Belt.

Machine washable, removable Upholstery.

Optional Accessories available:

Footrest Mounting Frame c/w multi-positional Footplates, Anklesure Foot

Controls, Sidearms with height and depth adjustment, Leg Abductors, Various

Harnesses and Pelvic Belt options. Clear plastic or Ply laminate Contoured

Trays (for use with G4-05-01 Sidearm Kits)

3

Gill 4 SEAT PLAN

RMS Type “D” Headrest

with angle-adjustable stem

Removable

Footrest Support

Frame

Padded

Pelvic Supports

Positive Locking

Swing-away

Thoracic Supports

Depth-adjustable

Backrest Support

Dynamic

Thrust Absorber

Removable and

Machine washable

Upholstery

Adjustable Anti-

Thrust Cushion

Height and

Depth-adjustable

Sidearms

Adjustable

Sacral Support

Fig. 1

4

SAFETY GUIDELINES

Due to the various activities that a wheelchair user has to perform, RMS Ltd

recommends that, prior to issuing the GILL 4 Seating System and the

wheelchair into which it is to be interfaced, this manual, together with any

wheelchair manufacturer’ User Guide, should be studied by all relevant

persons, to ensure that all instructions, procedures and warnings are carefully

observed and understood.

For correct support and user comfort, it is strongly recommended that the

initial installation any adjustments and final hand-over are carried out by a

suitably qualified person.

The maximum occupant capacity of a complete GILL 4 Seating System for

transportation purposes, when interfaced into a wheelchair with a seat width

up to 17”, is 50Kg (7.8 stones).

As the installation of a GILL III System may raise or position the user further

forward in their wheelchair, an appropriate stability test should be carried out

prior to final commissioning.

After the GILL 4 Seating System has been initially adjusted to suit the

individual user, any settings should not be affected subsequently, by the

removal and refitting of the Seat Unit to allow the wheelchair to be folded.

However, care should be taken not to impact adjustable components whilst

the Seat Unit is removed from the wheelchair, as this could affect their

original pre-set position.

To accommodate any changes in user growth or postural positioning, it is

recommended that the user be checked at regular intervals by a suitably

qualified person, to ensure that adjustable components are correctly set to

suit the user’s current requirements.

Carers should ensure correct utilisation of any positioning Straps or

Harnesses, as failure to do so could result in injury to the user. It is

recommended that any Postural Straps or Harnesses being used, are the

first items to be secured when the user enters the seat and the last items to

be released before exiting.

Worn or damaged upholstery can lead to hygiene contamination, cause

injury to the user and, in some cases, fail to support the user correctly.

Regular inspections of all upholstery should be made and any defects

should be reported to the relevant authority for rectification as soon as

possible.

Ancillary devices, such as the Headrest, positioning Straps and Harnesses,

Kneeblock or Pommel should be checked for security and positioning on a

daily basis.

The wheelchair parking brakes should always be applied before attempting

to transfer the occupant, removing or refitting the GILL 4 System or making

any adjustments.

Never hang heavy objects on the GILL 4 Seating System or any part of the

wheelchair, as this could seriously affect the overall wheelchair stability.

INITIAL INSTALLATION

The information contained in this User Manual, relates to the Gill 4 Seating

System being interfaced with an appropriate sized Otto Bock Discovery

wheelbase, fitted with an M30 Parallel Adapter Frame.

IMPORTANT NOTES:

The Gill 4 Seating System and Discovery wheelbase, when supplied as

a “G4—Disco Package”, will be assembled ready to be interfaced

together. However, the installer should note that whilst the Gill 4 and

Discovery will leave RMS Ltd set to the specifications detailed on the

original assessment prescription, some minor adjustments of either the

Seat or Backrest components may be necessary to ensure the final

correct seating support is achieved.

Any reference to Left or Right in this manual, will refer to the Left or

Right side when sitting forward facing in the Seat Unit.

Gill 4—Discovery Compatibility:

Where a Gill 4 Seating System is

supplied for use with a currently owned

Discovery wheelbase, it will be

necessary to ensure that the correct

*Interface Parallel Adapter, as detailed

below, is securely installed onto the

wheelbase in the most suitable position.

Gill 4 size 1—36cm Discovery only.

Use RMS G4 size 1 interface with

*M30 Parallel Adapter HR32048200

Gill 4 size 2—40cm Discovery only.

Use RMS G4 size 2 interface with

*M30 Parallel Adapter HR32048300

Gill 4 size 3—45cm Discovery only.

Use RMS G4 size 2 interface with

*M30 Parallel Adapter HR32048400

NOTE:

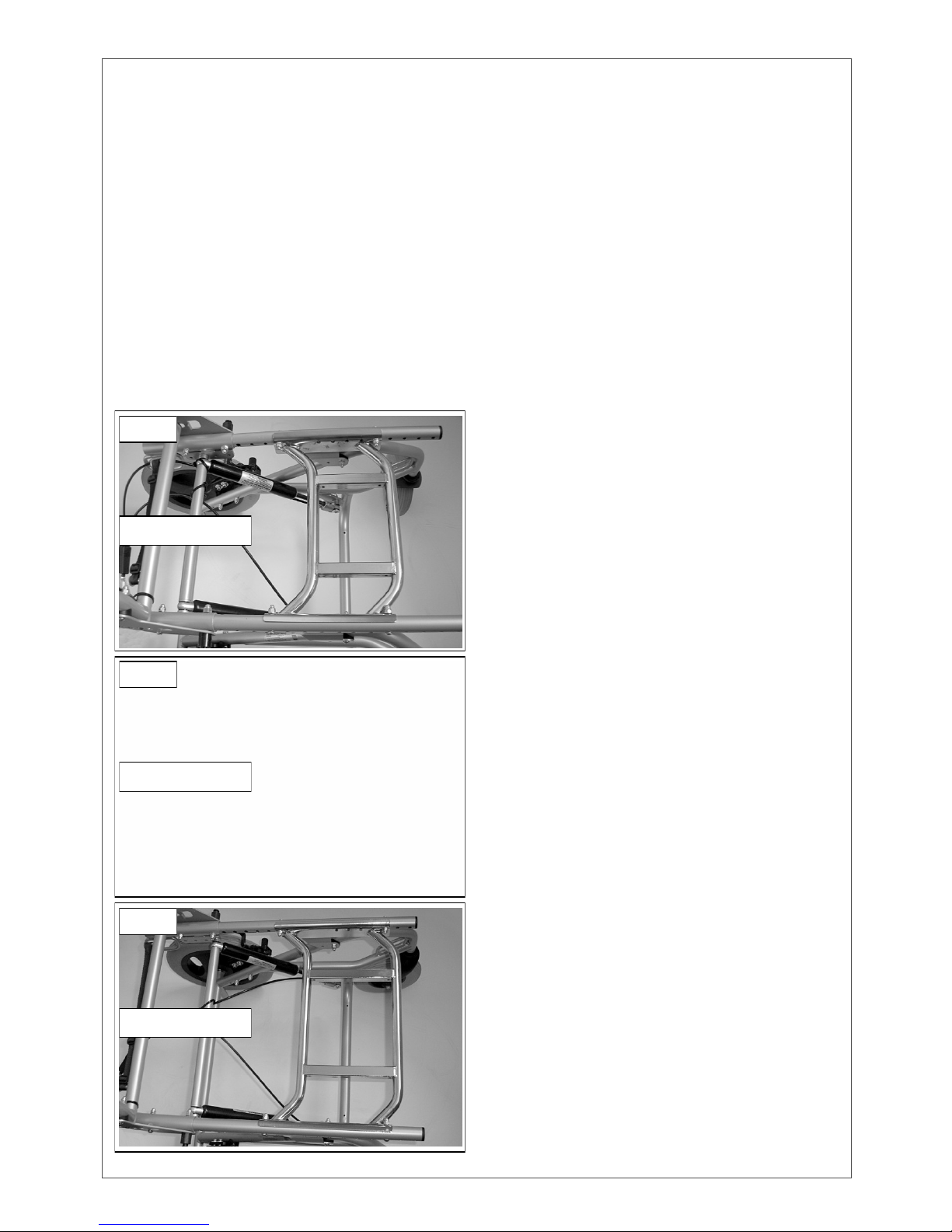

Whilst Figs.2, 3 and 4 give examples of

the Parallel Adapters fitted to three sizes

of Discovery wheelbases, some slight

adjustment of these may be necessary

where stability becomes an issue

created by changes in the user’s

disability.

5

Fig. 2

Fig. 3

Fig. 4

36cm Discovery

40cm Discovery

45cm Discovery

Table of contents

Other RMS Wheelchair manuals