SECTION 1: HEATER S AFETY

1

SECTION 1: HEATER SAFETY

Yo ur Safety is Important to Us!

This symbol is used throughout

the manual to notify youof possi-

ble fire, electrical or burn hazards.

Please pay special attention when

reading and following the warn-

ings in these sections.

Installation, service and annual

inspection of heater must be done by a contractor

qualified in the installation and service of gas-fired

heating equipment.

Read this manual carefully before installation, opera-

tion or service of this equipment.

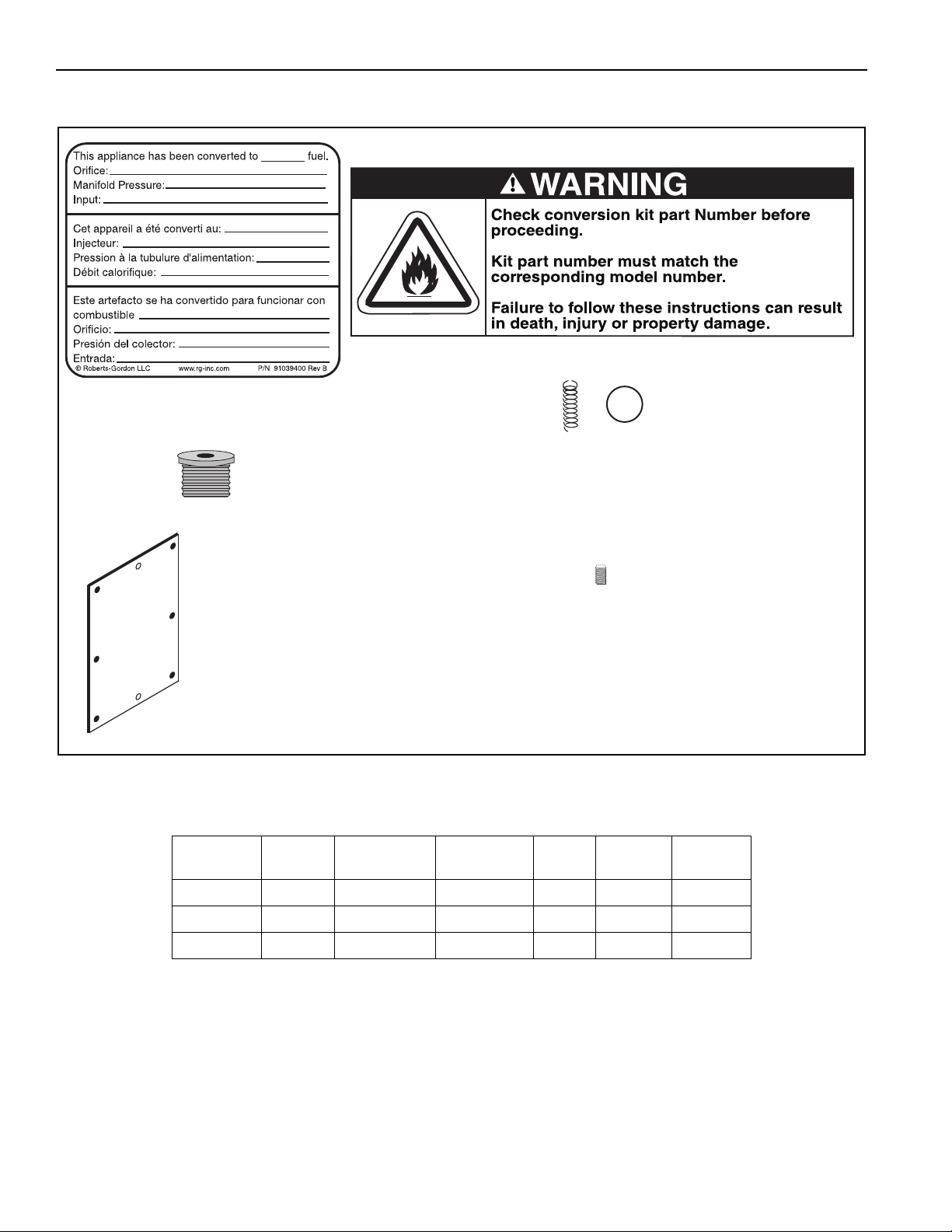

Due to the nature of gas conversions, it is important

youuse the correct conversion kit for the heater

model and gas youare converting to. Use only genu-

ine ROBERTS GORDON®conversion kits.

This heater is designed for heating residential and

nonresidential indoor spaces. Do not install in resi-

dential living and sleeping areas or basements.

These instructions, the layout drawing, local codes

and ordinances, and applicable standards that apply

to gas piping, electrical wiring, venting, etc. must be

thoroughly understood before proceeding with the

installation.

Protective gear is to be worn during installation,

operation and service. Thin sheet metal parts, includ-

ing the aluminum reflector portion of the heater and

the various venting components, have sharp edges.

To p r event injury, the use of work gloves is recom-

mended. The use of gloves will also prevent the

transfer of body oils from the hands to the surface of

the reflector.

Before installation, check that the local distribution

conditions, nature of gas and pressure, and adjust-

ment of the appliance are compatible.

This heater must be applied and operated under the

general concepts of reasonable use and installed

using best building practices.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowl-

edge, unless they have been given supervision or

instruction concerning use of the appliance by a per-

son responsible for their safety. Children should be

supervised to ensure that they do no play with the

appliance.

For additional copies of the Installation, Operation

and Service Manual, please contact Roberts-Gordon

LLC.

1.1 Manpower Requirements

To p re vent personal injury and damage to the heater,

two persons will be required to remove the heater

from the carton. Both ends of the heater should be

lifted from the carton at the same time. The burner

should be lifted by gripping the bottom. The reflector

of the heater should be lifted using the hanger.

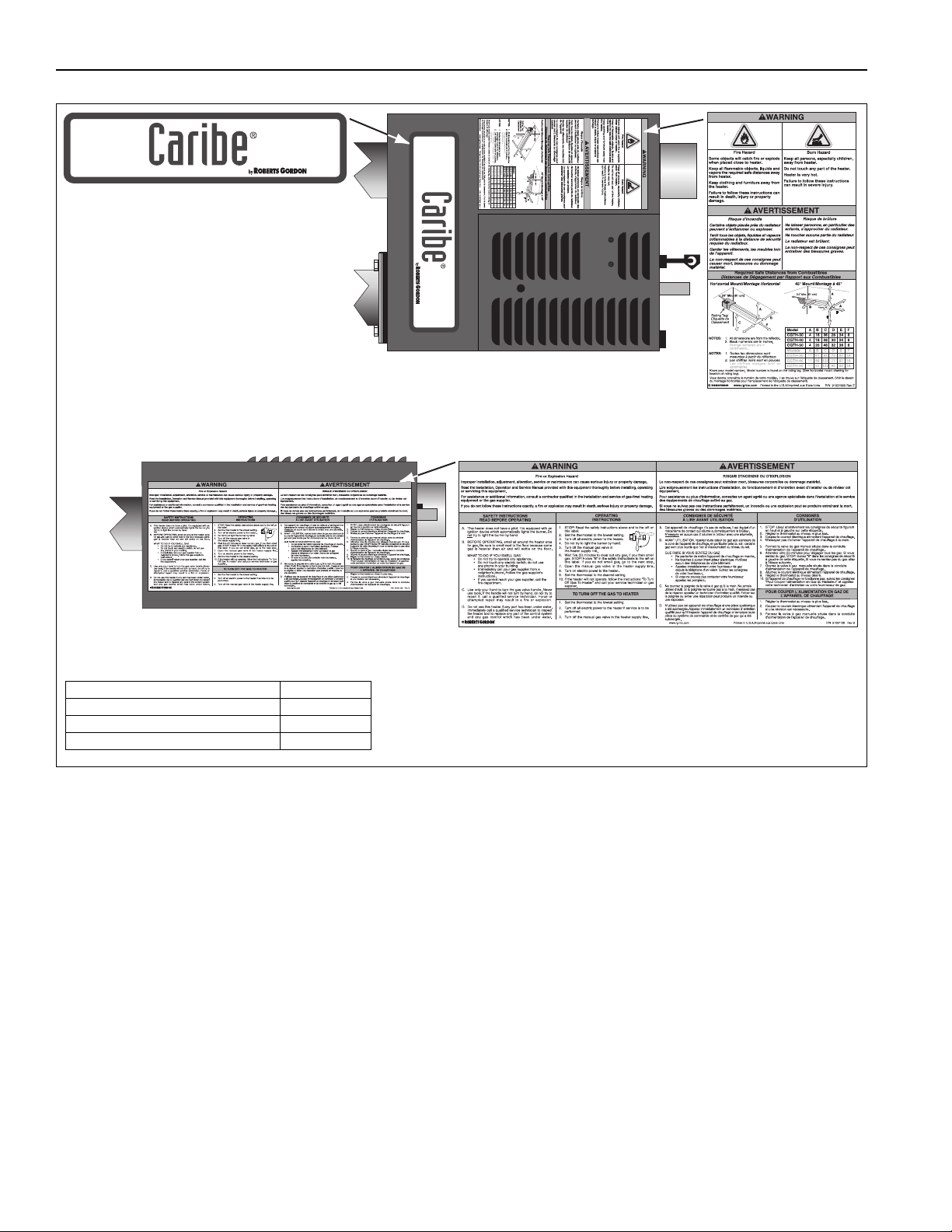

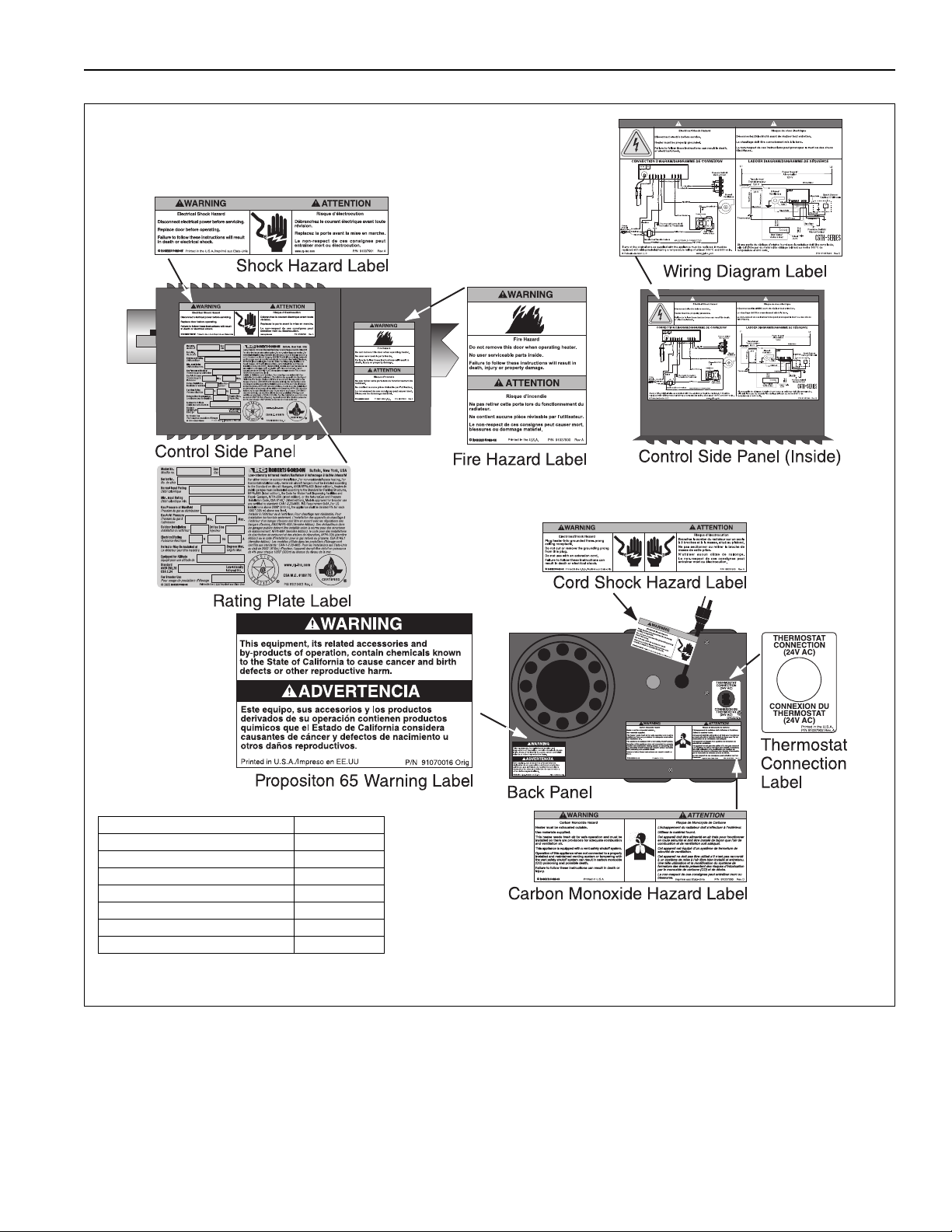

1.2 Safety Labels and Their Placement

Product safety signs or labels should be replaced by

the product user when they are no longer legible.

Please contact Roberts-Gordon LLC or your ROB-

ERTS GORDON®independent distributor to obtain

replacement signs or labels. See Page 2, Figure 1

through Page 3, Figure 2.

1.3 California Proposition 65

In accordance with California Proposition 65 require-

ments, a warning label must be placed in a highly

visible location on the outside of the equipment (i.e.,

near equipment’s serial plate). See label placement

drawing on Page 2, Figure 1 for label location. Avoid

placing label on areas with extreme heat, cold, corro-

sive chemicals or other elements. To order additional

labels, please contact Roberts-Gordon LLC or your

ROBERTS GORDON®independent distributor.