CAPILLARY CARE AND MOUNTING

1. Hold the capillary close to the control and carefully uncoil the

required amount. Minimize rebending which makes the capillary

more suscepble to breakage.

2. DO NOT cut the capillary or bulb. Avoid sharp bends, kinks, strains

or pinch marks in the capillary. Never allow the capillary to rest

against sharp edges or rub against metal surfaces.

3. Provide a drip loop in the capillary to prevent moisture from

reaching the control and causing an electrical short.

4. Don't immerse the excess capillary in the water bath or expose

it to temperatures above 120°F. Avoid exposing the capillary to

other extreme temperatures such as sucon or discharge lines.

5. Secure excess capillary in 3 inch coils to avoid damage from

vibraon or contact with electrical terminals. Sillicone adhesive

applied between the coils will prevent rubbing.

6. Although securing the excess capillary is important to dampen

vibraon, it is just as important to allow enough slack so the

capillary is not taut like a banjo string.

7. On startup of the equipment, observe the capillary for excessive

vibraon and make correcons as required.

BULB MOUNTING

1. Locate the bulb where the maximum build up of ice is to be

maintained since the enre bulb must be surrounded with ice to

stop the refrigeraon system.

2. A shorter cycle occurs when the bulb is located closer to the

expansion device; a longer cycle results when the bulb is located

closer to the outlet of the evaporator.

3. Using the strip clamp (when provided) or the original mounng,

aach the bulb to the evaporator coil at least 3 inches below the

water surface, away from a direct path of high velocity water.

The distance that the bulb is mounted from the evaporator coils

determines the ice bank thickness.

TYPICAL BULB MOUNTING

Figure 1 Using O18 Strip Clamp

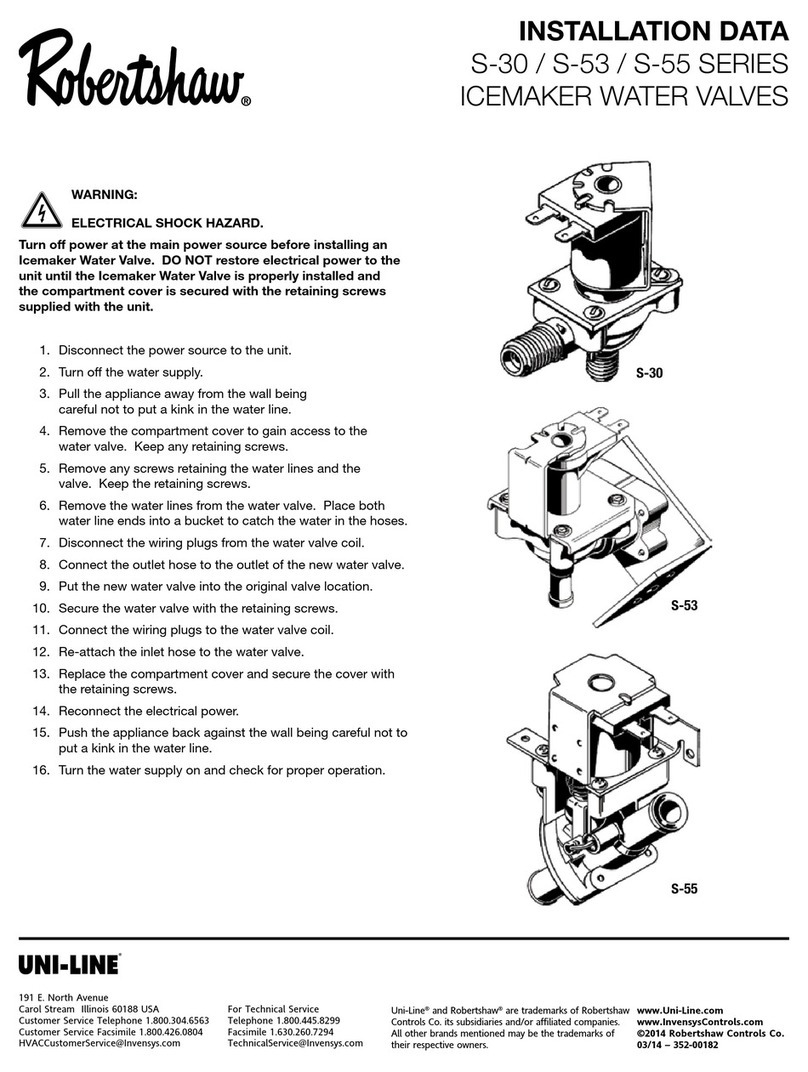

CONTROL WIRING

1. Disconnect electrical power to the unit.

2. All electrical wiring should conform to the Naonal Electrical code

and local regulaons.

3. DO NOT exceed the listed electrical rangs.

4. Use copper conductors only.

5. Provide a drip loop in the wiring to prevent moisture from

reaching the control.

6. The terminals must not be bent, cut o, drilled or retapped.

Electrical leads should not be taut; allow slack for temperature

change and vibraon.

When mounng a conduit connector to the O18 control frame, take

care to not damage the switch or the control mechanism.

The cup washers furnished with the O18 are to be used when the

conductor wires are directly connected to the terminals. The stripped

end of the conductor should be made into a clockwise formed eye with

an inside diameter to slip over the shank of the terminal screw. The

clockwise forming will tend to wrap the eye of the conductor around

the screw shank as it is being ghtened. The cup washer, with its

anges outward, should be placed between the terminal and the screw

head to capture the eye of the conductor.

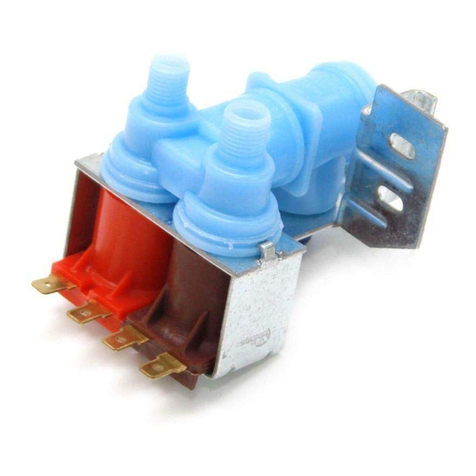

Figure 2 O18 Electrical Terminals

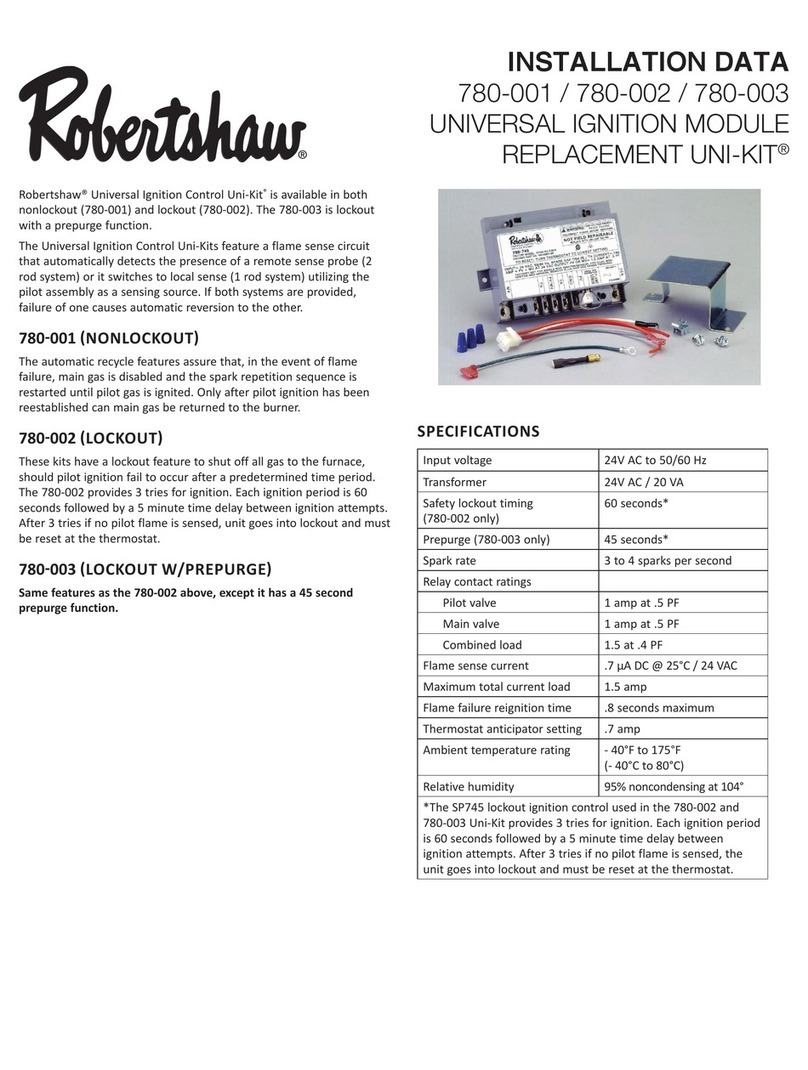

ELECTRICAL RATINGS

VAC FLA LRA PD VA HP

C12-1800 240 20 85 720

277 16 60 720

O18-100 120 17 102 720

240 17 102 720 3

241/600 — — 125

Hermec Compressor Motor

240 20 80

CHECKOUT

Inspect work to be assured that all the above steps were taken. Start

up the unit and arrange to observe at least one full cycle.

ALTITUDE ADJUSTMENT

The ice bank control is not aected by altude.

Customer Service Telephone 1.800.304.6563

Customer Service Facsimile 1.800.426.0804

Robertshaw®, Ranco®, Paragon® and Uni-Line® are

trademarks of Robertshaw, its subsidiaries and/or

affiliated companies. All other brands mentioned

may be the trademarks of their respective owners.

For Technical Service

Telephone 1.800.445.8299

Facsimile 1.630.260.7294

www.uni-line.com

www.robertshaw.com

©2015 Robertshaw

3/15 –153108 Rev C

1531080C.indd 2 3/13/15 3:58 PM