4

THE FOLLOWING ARE NOT COVERED

UNDER WARRANTY:

1 - Damage caused by abuse, misuse, dropping, or

other similar incidental damage caused by or as result

of failure to follow installation, assembly, operating,

cleaning, user maintenance or storage instructions,

including failure to verify and correct rotation of three

phase motors.

2 - Labor to sharpen and/or parts to replace knife

assemblies or blades which have become dull, chipped,

or worn due to normal use.

3 - Material or labor to renew or repair scratched,

stained, chipped, dented, or discolored surfaces, blades,

knives, attachments, or accessories.

4 - Transportation charges to or from an authorized

service agency for repairs of a machine designated as

“CARRY IN SERVICE” (Table Top Models).

5 - Labor charges to install or test attachments or

accessories (i.e. bowls, cutting plates, blades,

attachments) which are replaced for any reason.

6 - Charges to change Direction-of-Rotation of Three

Phase electric motors (INSTALLER IS RESPONSIBLE). All

Robot Coupe products must operate counter-clock-wise.

7 - SHIPPING DAMAGE IS NOT COVERED BY

WARRANTY. Visible and hidden damages are the

responsibility or the freight carrier. The consignee must

file a damage claim promptly against the carrier, or

upon discovery in the case of hidden damage.

8 - Any ROBOT COUPE COMMERCIAL PRODUCT

used in an Industrial application.

Commercial equipment use is defined as but not limited

to the preparation of food substance within the confines

of a restaurant/facility, that is sold and consumed within

said restaurant/facility.

Industrial equipment use is defined as but not

limited to the manufacturing of food substance in

large batch quantities. The processed food is then

packaged and sold off site and or to a distributer for

resale off site.

KEEP ALL ORIGINAL CONTAINERS AND PACKING

MATERIALS FOR CARRIER INSPECTION

All Robot Coupe equipment should be operated in

an ambient room temperature of 60 degrees (F) or

higher.

Robot Coupe U.S.A., Inc., Robot Coupe S.A., or

any of their affiliates, distributors, officers, directors,

agents, employees or insurers will not be obligated for

consequential or other damages, losses, or expenses

in connection with or by reason of the use of or the

inability to use the machine for any purpose.

THIS WARRANTY IS GIVEN EXPRESSLY AND IN LIEU

OF ALL OTHER WARRANTIES EXPRESSED OR IMPLIED,

FOR MERCHANTABILITY AND FOR FITNESS TOWARD

A PARTICULAR PURPOSE AND CONSTITUTES THE

ONLY WARRANTY MADE BY ROBOT COUPE, U.S.A.,

Inc.

YOUR NEW ROBOT COUPE COMMERCIAL

PRODUCT IS WARRANTED TO THE

ORIGINAL PURCHASER FOR A PERIOD OF

ONE YEAR FROM THE DATE OF PURCHASE.

This LIMITED COMMERCIAL WARRANTY

is against defects in the material and / or

workmanship, and includes labor for

replacement of defective parts, provided

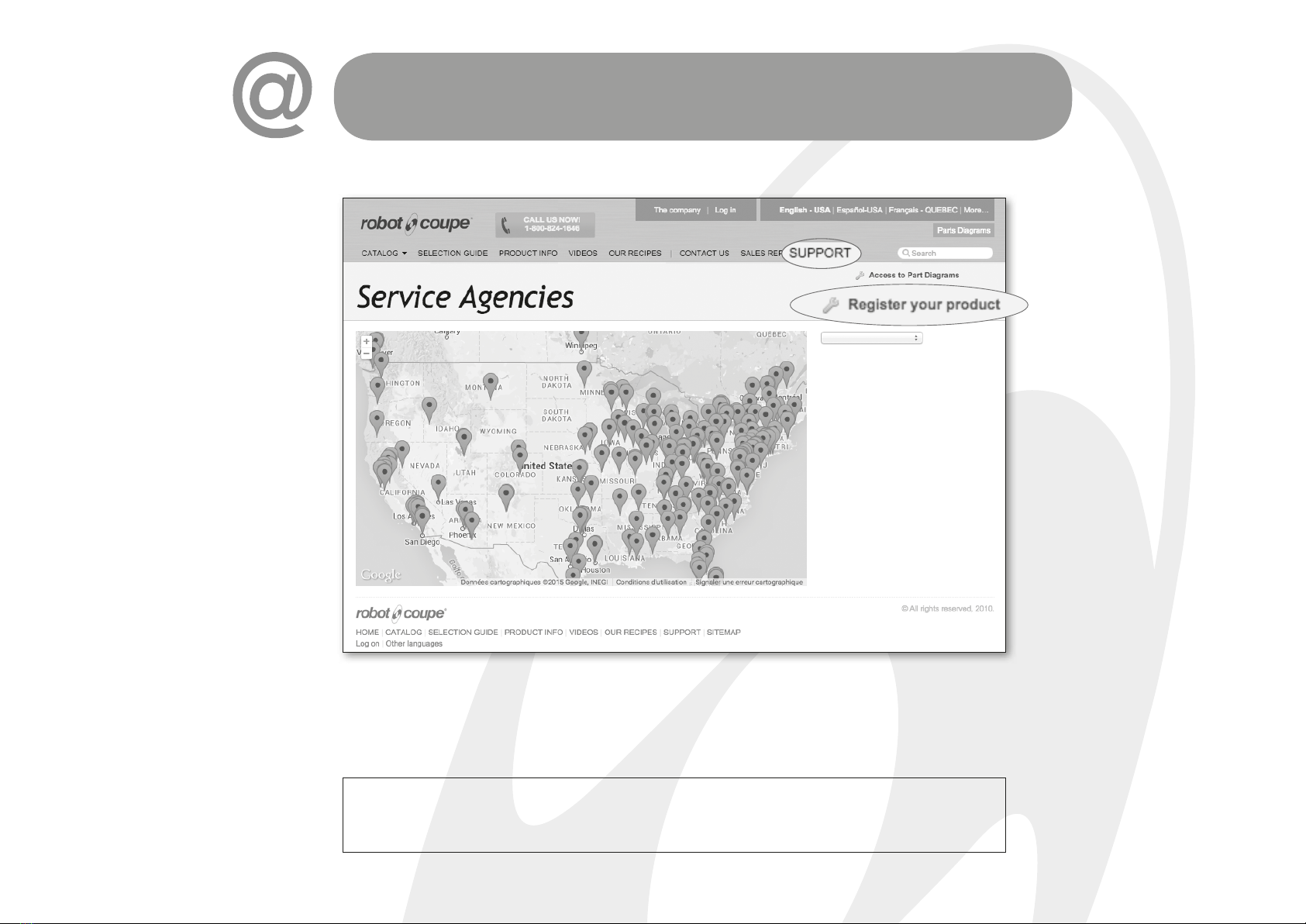

repairs are performed by an authorized

service agency (see attached list). The

CUSTOMER must inform the Service Agency

of the possibility of warranty coverage

and provide a copy of the dated sales

or delivery receipt BEFORE WARRANTY

REPAIRS ARE BEGUN. All parts or

accessories replaced under warranty must

be returned to the Service Agency. The

warranty for work done or parts replaced

under warranty expires at the end of the

original warranty period.

Replacement parts and accessories are

warranted for ninety (90) days from

the date of purchase when purchased

separately and will be verified by dated

sales receipt OR packing slip which list that

item.

All Robot Coupe Products are considered

commercial use only.

ROBOT COUPE U.S.A., INC. ONE YEAR LIMITED COMMERCIAL WARRANTY