To make French fries a special equipment is required,

available in two dimensions 8 x 8 and 10 x 10 mm.

Only the CL 55 Automatic feed head can realize

French fries.

FRENCH FRIES

F 8x8

potato

F 10x10

potato

F 10x16

potato

20

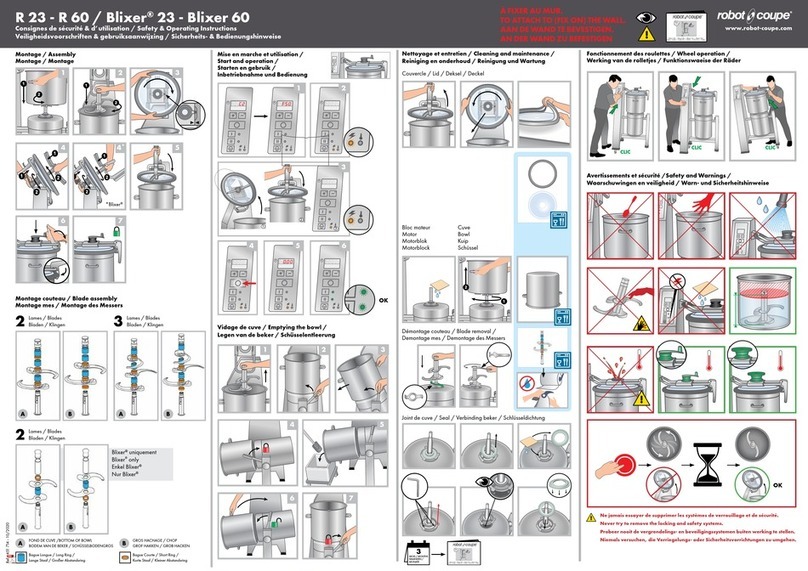

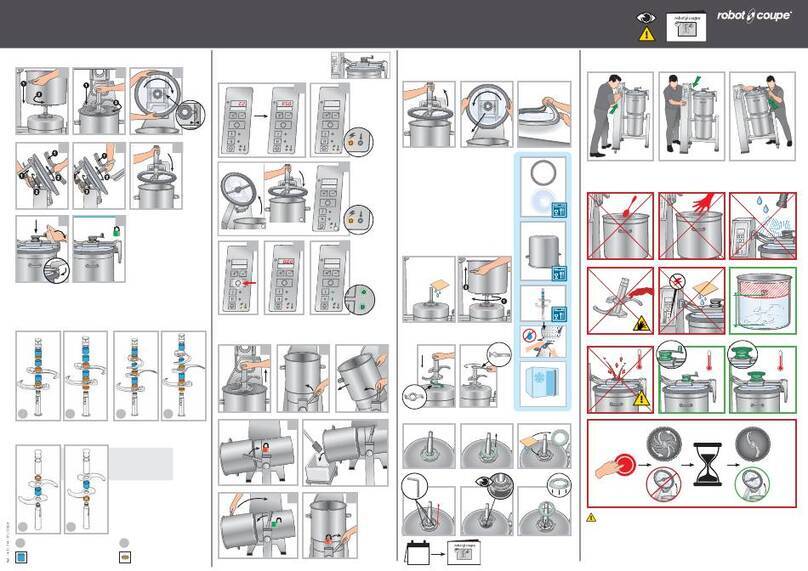

CLEANING

Next clean all the parts.

Dishwashers are best avoided in order to prevent

the aluminium from becoming tarnished. Instead we

recommend that you clean the machine by hand using

washing-up liquid.

If you do put your machine in a dishwasher, we

suggest that you use a detergent designed specially

for aluminium.

Never immerse the motor base in water. Clean it

with a damp cloth or sponge.

JULIENNE

J 1x8

carrot / celeriac / potato / courgette

J 2x2

carrot / celeriac / potato

J 2x4

carrot / beetroot / courgette / potato

J 2x6

carrot / beetroot / courgette / potato

J 2x10

carrot / beetroot / courgette / potato / celeriac

J 4x4

egglant / beetroot / courgette / potato

J 6x6

egglant / beetroot / celeriac / courgette / potato

J 8x8

céleriac / patato

DICE

D 5x5

carrot /courgette / cucumber / celeriac

D 8x8

potato / carrot / courgette / beetroot

D 10x10

potato / carrot / courgette / beetroot /turnip /

onion / apple (fruit)

D 14x14

potato / carrot / courgette / turnip / celeriac

M 20x20

potato / carrot / courgette / pineapple / turnip

M 25x25

potato / courgette / turnip / apple (fruit) / melon / watermelon

SLICERS

S 0,6

amands

S 0,8

cabbage

S 1 carrot /

cabbage / cucumber / onion / potato / leek

S 2 / S 3

lemon / carrot / mushroom / cabbage / potato / cucumber /

courgette / onion / leek / bell pepper

S 4 / S 5

courgette / beetroot / carrot /mushroom / cucumber /

bell pepper /radish / lettuce / potato / leek / tomato

S 8 / S 10

courgette / potato / courgette / carrot

S /1 4

potato / courgette / carrot

RIPPLE CUT SUCER

R 2

beetroot / potato / carrot / courgette

R 3

beetroot / potato / carrot / courgette

R5

beetroot / potato / carrot / courgette

GRATER

G1,5

celeriac / cheese

G 2

carrot / celeriac / cheese

G 3

carrot

G 5

cabbage / cheese

G7

cabbage / cheese

G 9

cabbage / cheese

Parmesan/chocolate

Radish

MAINTENANCE

• BLADES, PLATES AND GRATERS

The blades on the slicing discs, the plates on the

julienne discs and the graters are all subject to wear

and have to be changed every so often to ensure

high quality cutting.

Always use a properly cleaned grid. Never process

soft foodstuffs after hard ones without properly

cleaning the grid beforehand.

5) Then fit the discharge disc, the slicing, grating or

julienne disc, or the dicing equipment as described

in steps 1) and 2) in the previous section on the

relevant hopper.

6) Close the hid using the fastening hook.

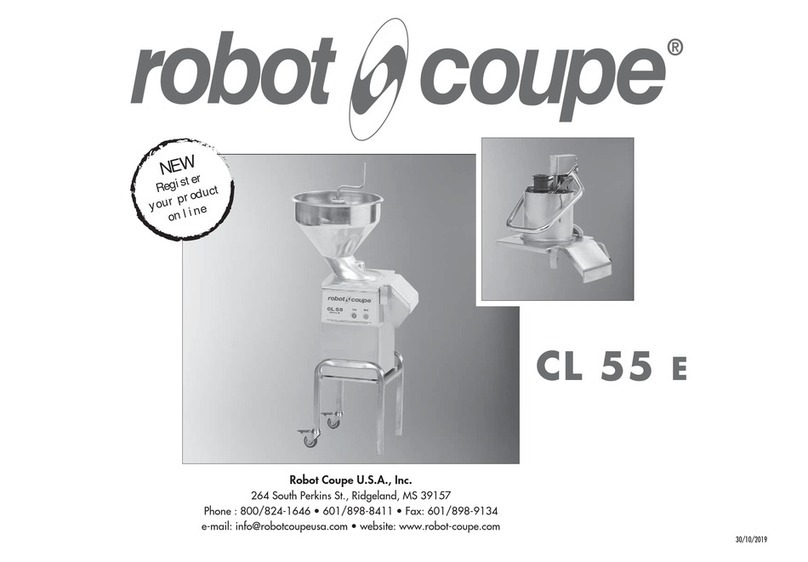

USES AND

CHOICE OF DISCS

Complete range of perfectly balanced, pressurized

aluminium discs guaranteeing perfect cutting quality

and allowing all types of fruit and vegetable

preparation including slicing, wavy cutting, grating,

julienne cutting, shredding, dicing and French fries

potatoes cutting.

WARNING

After releasing the hinge and unlocking the fastening

hook, remove the head of the vegetable preparation

machine and then take out the disc, lifting it by its

edge, and if necessary remove the grid and its

support followed by the discharge disc.

IMPORTANT

As a precaution, always unplug your appliance

before cleaning it (risk of electrocution).

Check that your detergent is suitable for

cleaning plastic parts. Some washing agents

are too alkaline (e.g. high levels of caustic soda

or ammonia) and totally incompatible with

certain types of plastic, causing them to

deteriorate rapidly.