Rocker Tanfil 100 User manual

Other Rocker Laboratory Equipment manuals

Rocker

Rocker Lafil 300- LF 30 User manual

Rocker

Rocker Rocker 300 User manual

Rocker

Rocker Galaxy 330 User manual

Rocker

Rocker CD 200 User manual

Rocker

Rocker Lafil 200 User manual

Rocker

Rocker BioVac 225 User manual

Rocker

Rocker 197000-36 User manual

Rocker

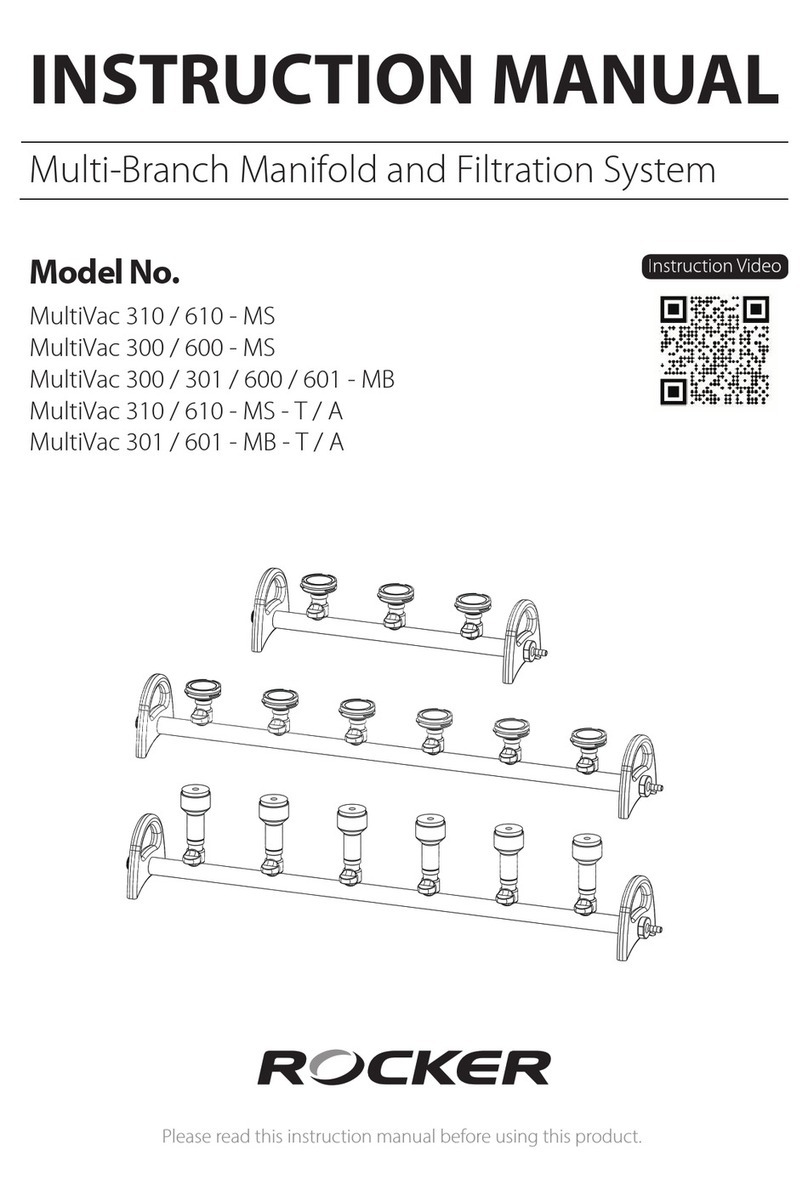

Rocker MultiVac 310-MS User manual

Rocker

Rocker MultiVac 310-MS User manual

Rocker

Rocker CR 25 User manual

Popular Laboratory Equipment manuals by other brands

Agilent Technologies

Agilent Technologies 5800 ICP-OES user guide

Endress+Hauser

Endress+Hauser Cleanfit CPA875 operating instructions

NI

NI PXI-5422 CALIBRATION PROCEDURE

Collomix

Collomix Aqix operating instructions

SPEX SamplePrep

SPEX SamplePrep 6875 Freezer/Mill Series operating manual

Ocean Insight

Ocean Insight FLAME-NIR+ Installation and operation manual

Parker

Parker ALIGN-MG-NA Installation, operation and maintenance manual

BD

BD 644787 user guide

DENTAURUM

DENTAURUM Compact Megaplus Instructions for use

Biuged Laboratory Instruments

Biuged Laboratory Instruments BGD 626 instruction manual

VWR

VWR SAS Super IAQ instruction manual

illumina

illumina MiSeqDx reference guide