Rockwell Automation Allen-Bradley PowerFlex 6000T User manual

Other Rockwell Automation DC Drive manuals

Rockwell Automation

Rockwell Automation PowerFlex 6000 User manual

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 755TS Series Service manual

Rockwell Automation

Rockwell Automation Reliance electric 6SB401 Series User manual

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 400P Series User manual

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 4M User manual

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 7000 User manual

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 755T Series User manual

Rockwell Automation

Rockwell Automation Allen-BradleyPowerFlex 700H User manual

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 700 Series User manual

Rockwell Automation

Rockwell Automation RELIANCE ELECTRIC SP120 User manual

Rockwell Automation

Rockwell Automation PowerFlex 700S User manual

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 7000 User manual

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 7000 Series User manual

Rockwell Automation

Rockwell Automation PowerFlex 755TM User manual

Rockwell Automation

Rockwell Automation PowerFlex 7000 User manual

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 750 Series User manual

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 40 FRN Series User manual

Rockwell Automation

Rockwell Automation Allen-Bradly 1397 User manual

Rockwell Automation

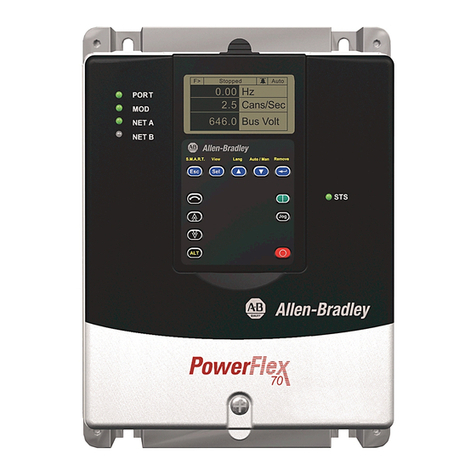

Rockwell Automation PowerFlex 700 Instructions for use

Rockwell Automation

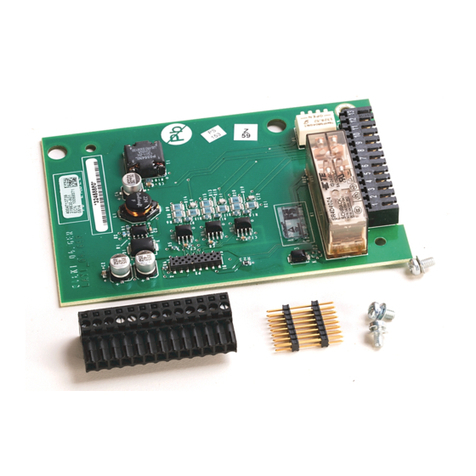

Rockwell Automation Allen-Bradley DriveGuard 20D-P2-DG01 User manual

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 20P User manual

Rockwell Automation

Rockwell Automation Allen Bradley PowerFlex40 User manual

Rockwell Automation

Rockwell Automation Allen-Bradley IMPACT 1336 Series Programming manual

Rockwell Automation

Rockwell Automation RELIANCE ELECTRIC DC3N Series User manual