Product Information

Original Instructions

GuardShield Micro 400 Safety Light Curtains

Catalog Numbers 445L-P4xFP, 445L-C4xFP, 445L-P4xKP

Only use the GuardShield Micro 400 safety light curtain as defined in these

instructions and publications that are listed in Additional Resources on page 6.

Only qualified personnel can install, commission, service, and use this safety light

curtain, and only on the machine that the device was intended.

If the device is used for any other purposes or modified in any way, warranty

claims against Allen-Bradley/Guardmaster become null and void.

The national/international rules and regulations apply to the installation, use, and

periodic technical inspections of the safety light curtain, in particular:

• Machinery Directive 2006/42/EC

• Low Voltage Directive 2014/35/EU

• Use of Work Directive 2009/104/EC

• The work safety regulations/safety rules

• Other relevant health and safety regulations

Manufacturers and users of the machine that uses the safety light curtain are

responsible for obtaining and observing all applicable safety regulations and rules.

Specifications

ATTENTION:

• Do not use the GuardShield™ Micro 400 safety light curtain with

machines that cannot stop electrically in an emergency.

• Always maintain the safety distance between the GuardShield

Micro 400 safety light curtain and a dangerous machine

movement.

• Install additional mechanical protective devices so you cannot

reach the hazardous machine elements without passing

through the protective field.

• Install the GuardShield Micro 400 safety light curtain so you can

only access the hazard through the sensing field.

• Improper installation can result in serious injury.

• Never connect the outputs to +24V DC. If the outputs connect to

+24V DC, they are in the on-state and cannot stop hazardous

spots at the machine/application.

• Never expose the GuardShield Micro 400 safety light curtain to

flammable or explosive gases.

• Regular safety inspections are imperative (see

Inspection on page 4).

IMPORTANT Observe the following items to maintain the proper and

safe use of the GuardShield Micro 400 safety light curtain.

Table 1 - Safety Ratings

Attribute Standard IP69K

Standards IEC/EN 61496 Parts 1 and 2, UL61496 Parts 1 and 2, UL1998

Safety classification Type 4 per IEC/EN61496. Category 4 device per EN 13849-1 SIL 3 per

IEC 61508, PLe per EN/ISO 13849-1

Probability of a dangerous

failure per hour PFH • 6.0 E-9 1/h MSR42 or MSR41 safety module, and MSR45E extension module

• 4.0 E-9 1/h Micro 400 safety light curtain

Certifications cULus Listed, TÜV Certified, CE Marked for all applicable EU directives, UKCA

Marked for all applicable regulations, and RCM Marked (Australia)

rok.auto/certifications

Table 2 - Outputs

Attribute Standard IP69K

Micro 400 safety light

curtain outputs Data output to controller (MSR41 or MSR42 safety module)

MSR41/MSR42 safety

module outputs Two 400 mA OSSD

Non-safety outputs Auxiliary outputs from MSR41 or MSR42 safety module

2 configurable 100 mA, outputs

Switching current at

voltage, max 400 mA at 24V DC

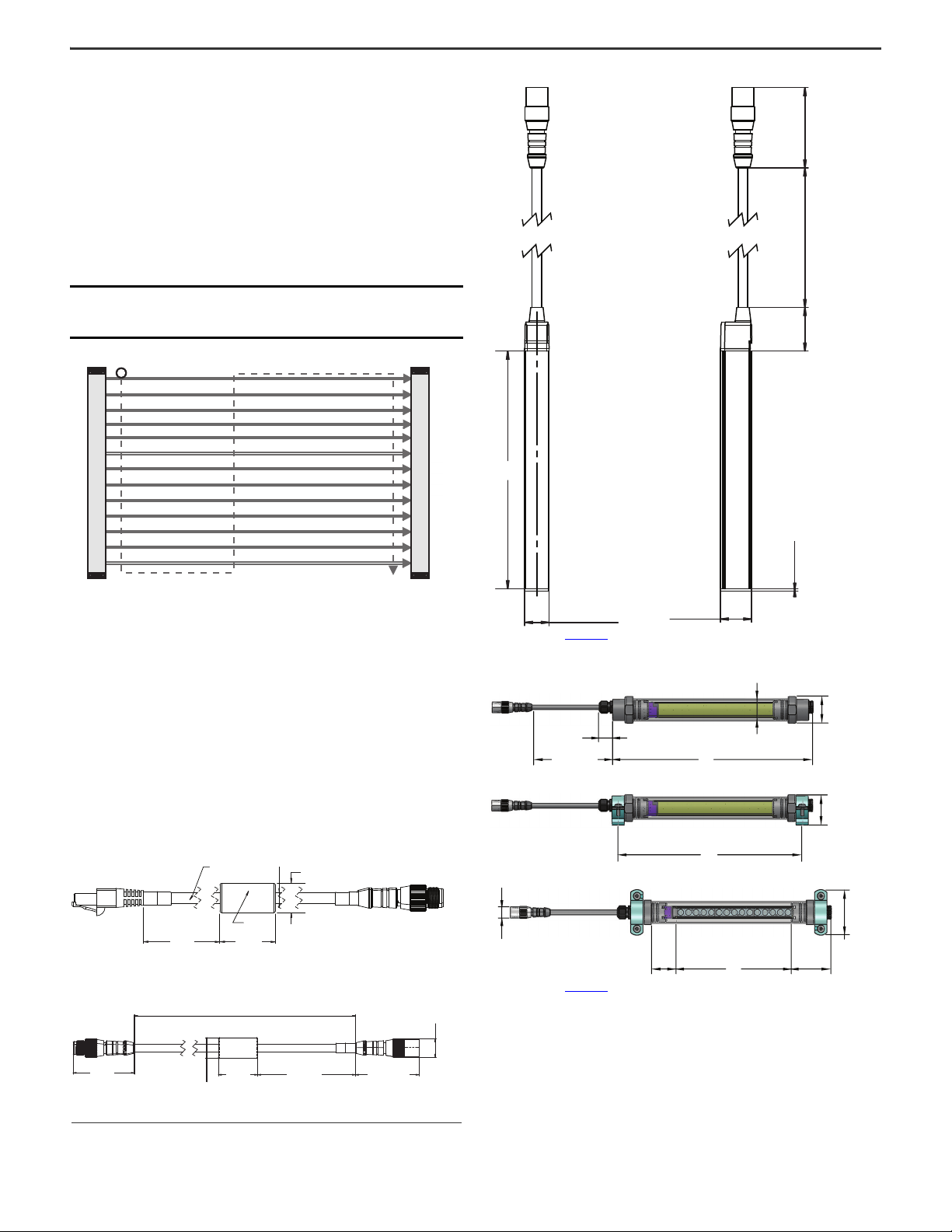

Table 3 - Operating Characteristics

Attribute Standard IP69K

Response time

• 14 mm (0.55 in.): 12…42 ms, varies by protective height and resolution,

protective height 150…1200 mm (5.95…47.24 in.)

• 30 mm (1.18 in.); 11…23 ms, varies by protective height and resolution,

protective height 150…1200 mm (5.95…47.24 in.)

Status indicators On-state, Off-state, Intensity, Lockout

Protected height [mm

(in.)] • Standard slim profile: 50…1200 (1.97…47.2) in 50 (1.97) increments

• Reinforced profile: Up to 2200 (86.6)

Resolution [mm (in.)] 14 (0.55), 30 (1.18), or PAC (perimeter)

Scanning range/

resolution, min

• 14 mm (0.55 in.) resolution:

0…5 m (16.4 ft)

• 30 mm (1.18 in.) resolution:

0…5 m (16.4 ft)

• 14 mm (0.55 in.) resolution:

0…2.5 m (0…8.2 ft)

•30mm(1.18in.)resolution:

0…2.5 m (0…8.2 ft)

Synchronization Electrical through MSR41 or MSR42 safety module

Wave length 940 nm

Time for self-check when

switching on Usp < 5 s

Table 4 - Environmental

Attribute Standard IP69K

Enclosure type rating • Micro 400 safety light curtain:

IP54

•Plug:IP65

• Micro 400 safety light curtain:

IP65, IP66, IP67, IP68, IP69K

Relative humidity 15…95% (noncondensing)

Operating temperature

[°C (°F)] 0…55 (14…131)

Storage temperature

[°C (°F)] -20…+70 (4…158)

Vibration IEC 60068-2-6; Frequency 10…55 Hz; Amplitude 0.35 mm (0.01 in.)

Shock IEC 60068-2-29; Acceleration 10 g, pulse duration 16 ms 10…55 Hz;

Amplitude 0.35 mm (0.01 in.)

Power supply Input power from MSR41 or MSR42 safety module

Input power, max 24V DC ±15% (MSR41 or MSR42 safety module)

Maximum residual ripple 5% of Vss

Power consumption, max

(no load) 0.07 A

Equipment class III (VDE 0106 part 100)

EMC IEC 61496 part 1