Rohl AQUITAINE U.1323 User manual

Other Rohl Plumbing Product manuals

Rohl

Rohl TENERIFE TTE18W1LMMB User manual

Rohl

Rohl MATHESON ML2013LMAPC User manual

Rohl

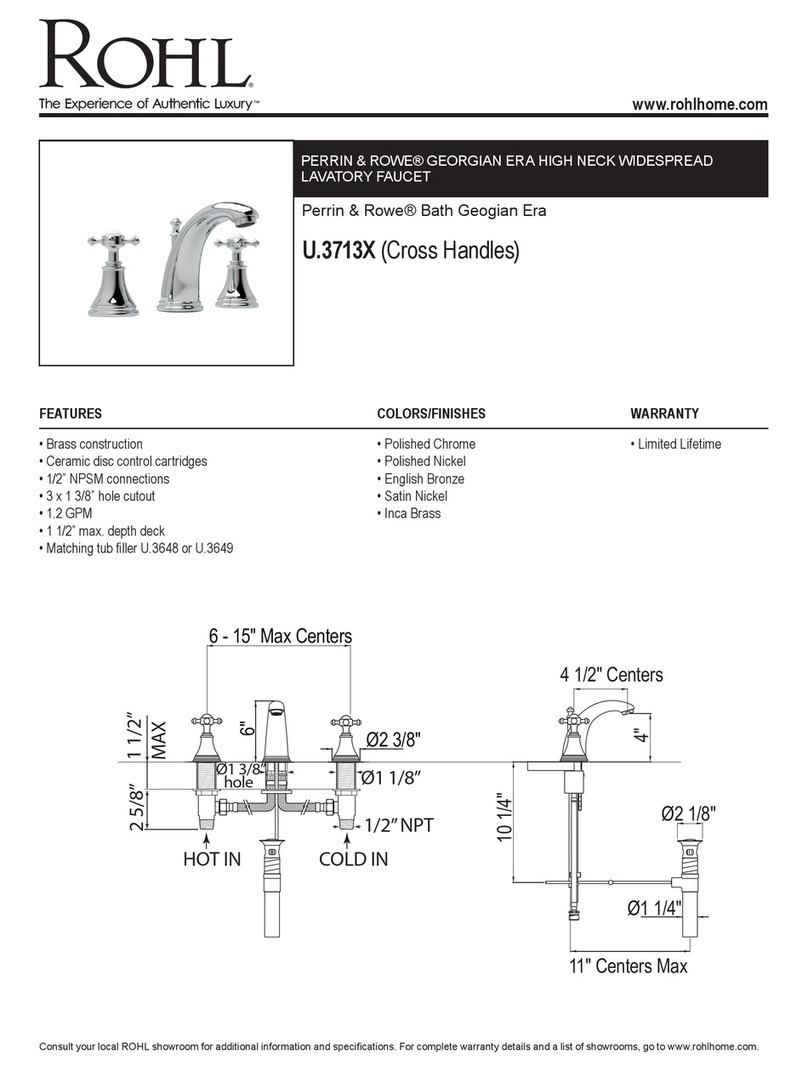

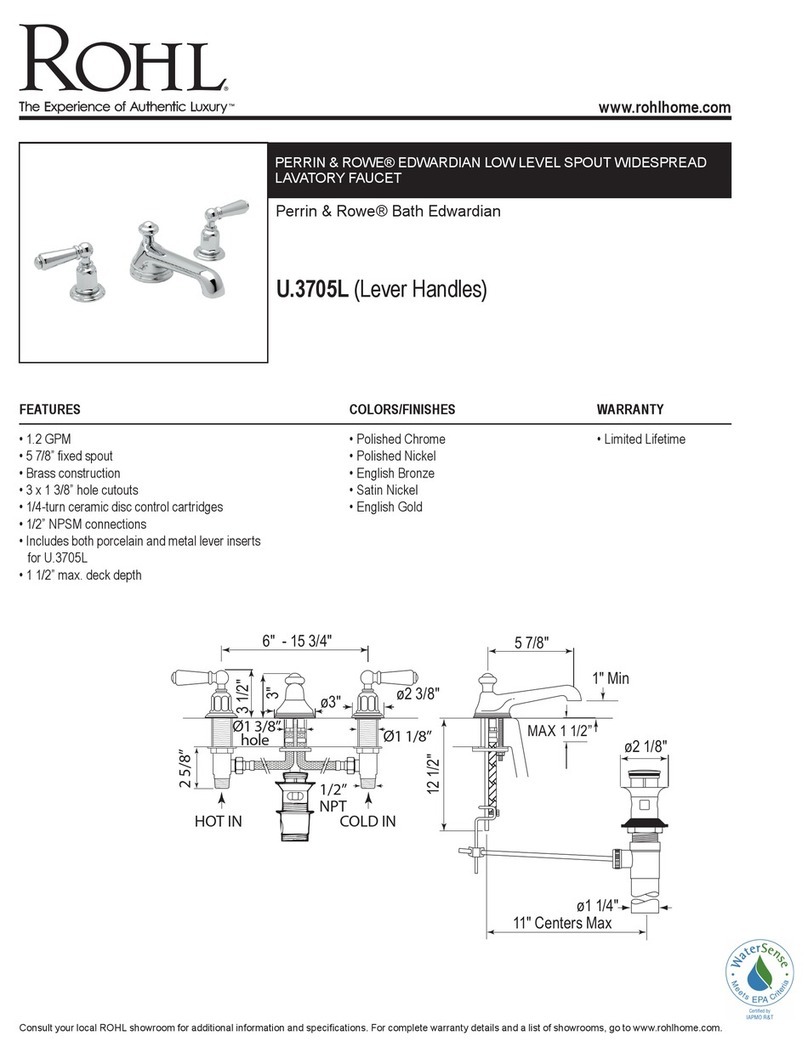

Rohl PERRIN & ROWE EDWARDIAN U.3705L User manual

Rohl

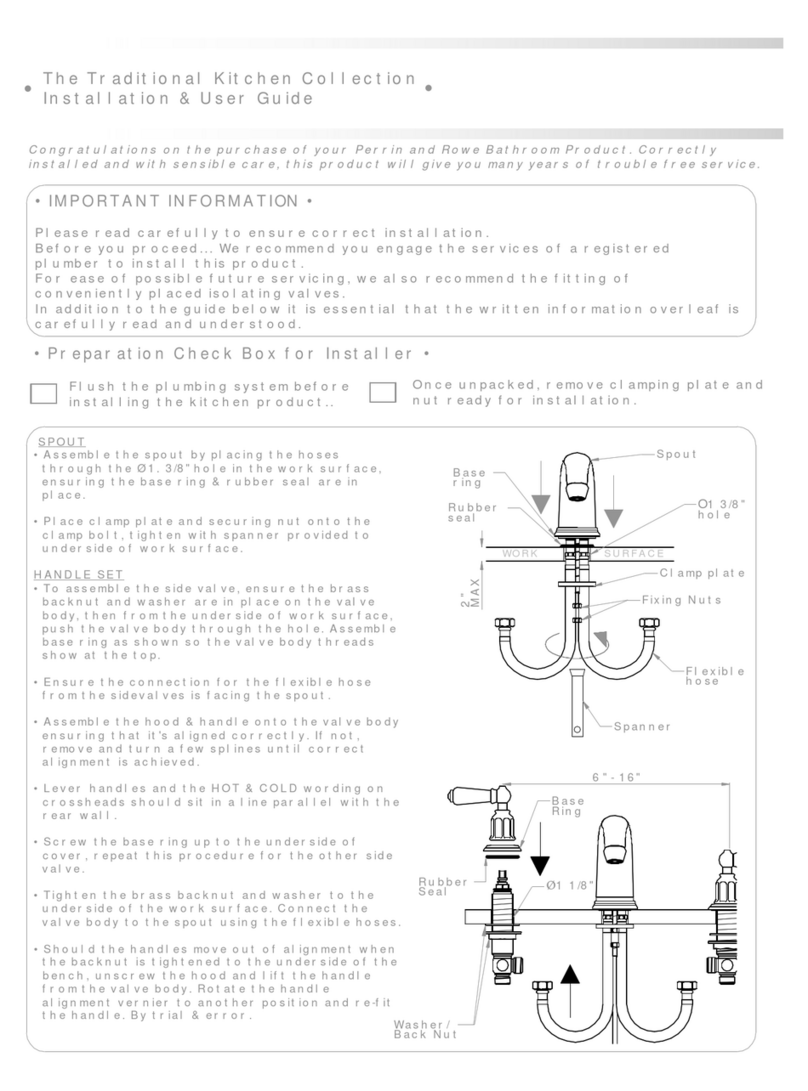

Rohl Traditional Kitchen Edwardian U3706XEG2 Operation manual

Rohl

Rohl PERRIN & ROWE U.3706X Series User manual

Rohl

Rohl Perrin & Rowe GEORGIAN ERA U.KIT1307 User manual

Rohl

Rohl CASWELL CA2217STN User manual

Rohl

Rohl PERRIN & ROWE U.3721X User manual

Rohl

Rohl PERRIN & ROWE GEORGIAN ERA U.1307LS User manual

Rohl

Rohl RUWUM3019WSSB User manual

Rohl

Rohl Myrina MY55D1 User manual

Rohl

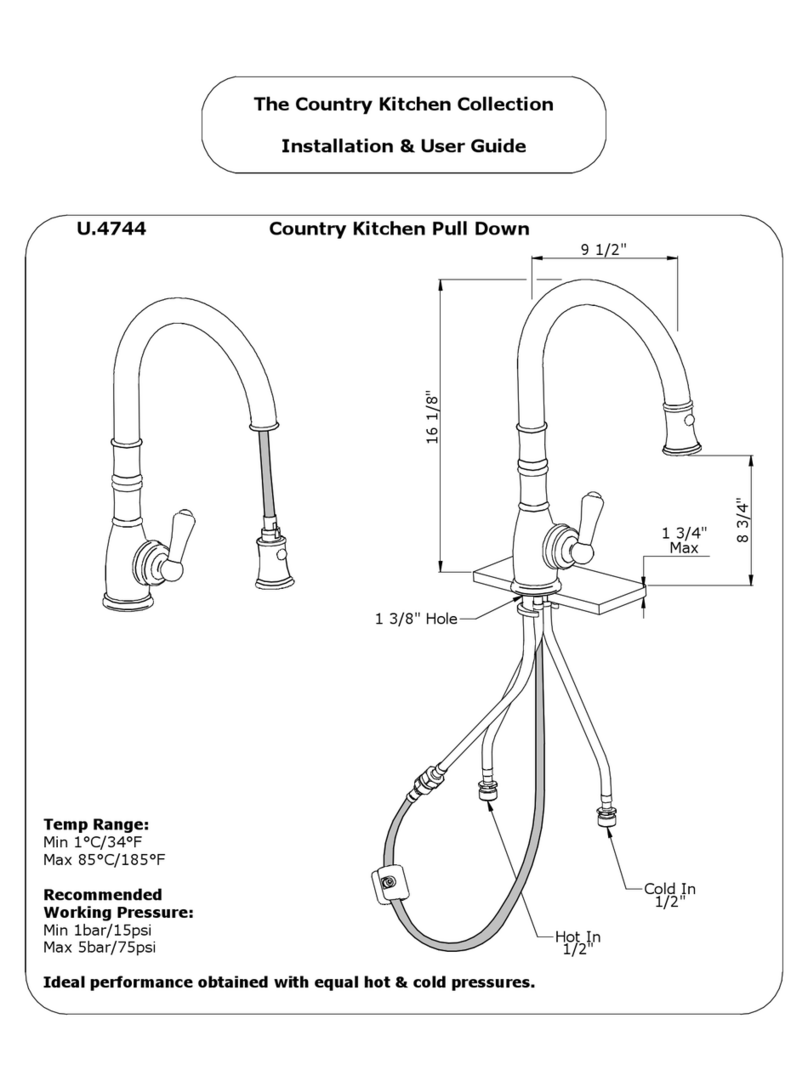

Rohl Georgian Era U.4744 Operation manual

Rohl

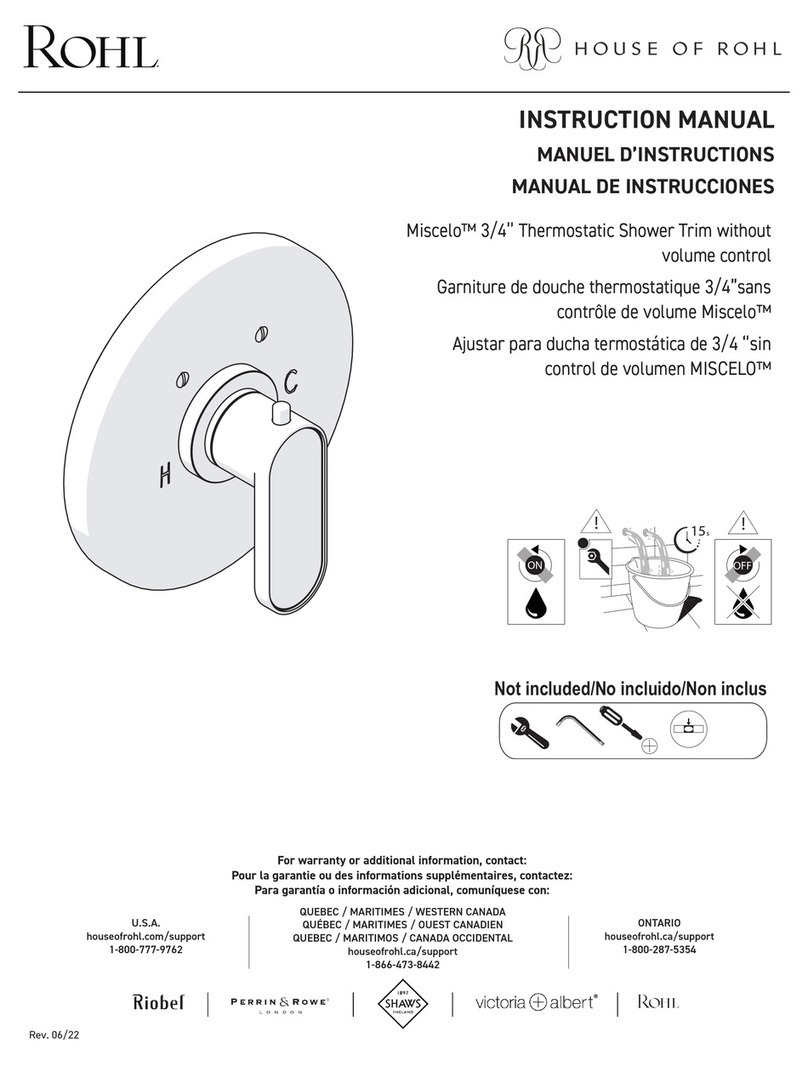

Rohl Miscelo MI12W2SDSTN User manual

Rohl

Rohl Perrin & Rowe U.3720L User manual

Rohl

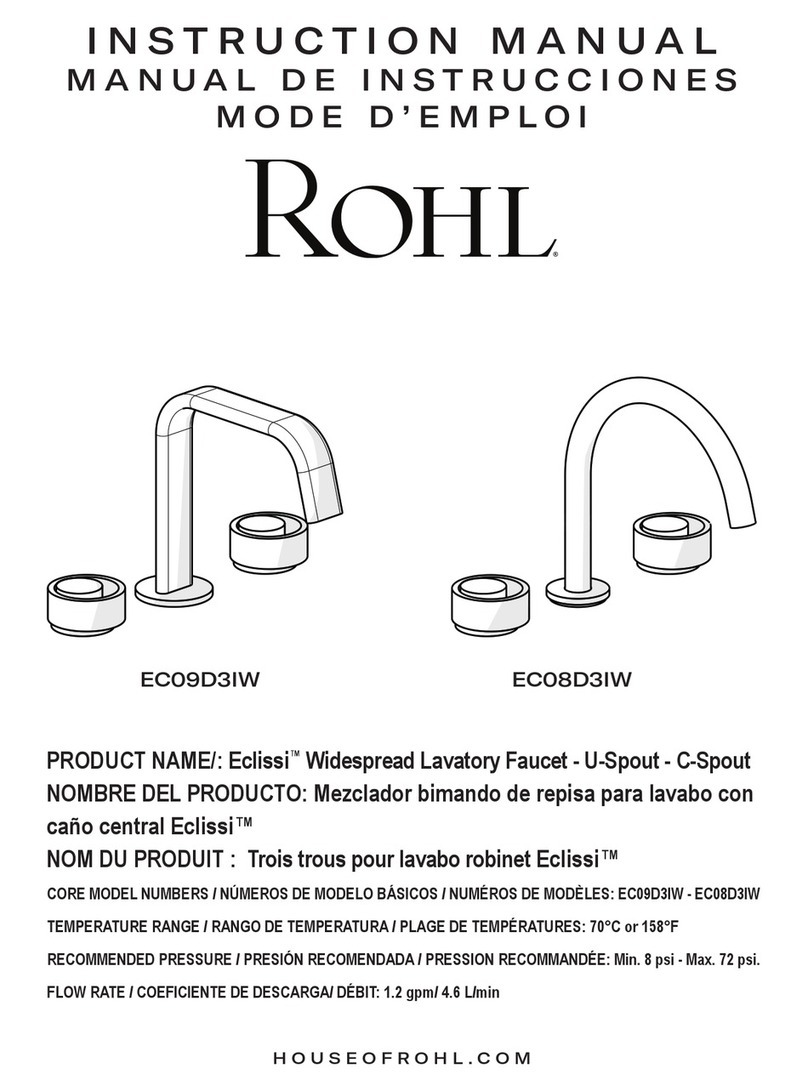

Rohl Eclissi EC09D3IW User manual

Rohl

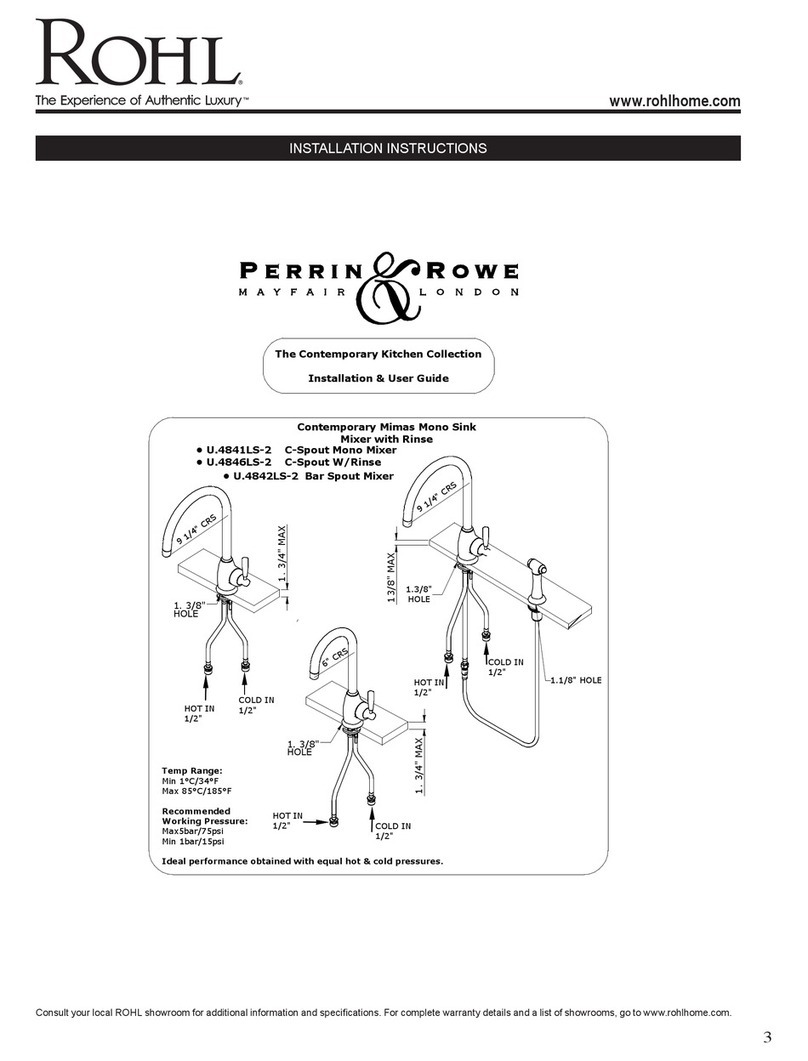

Rohl PERRIN & ROWE MAYFAIR LONDON U.4841LS-2 User manual

Rohl

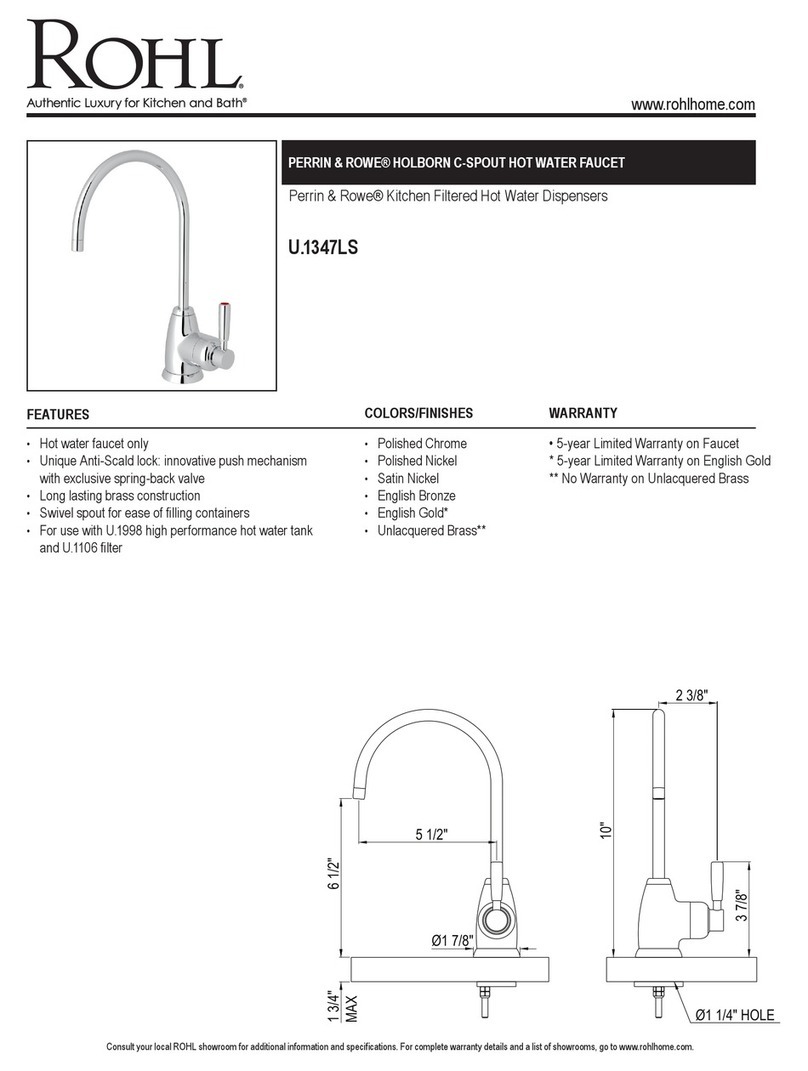

Rohl Perrin & Rowe U.1347LS User manual

Rohl

Rohl A8800 User manual

Rohl

Rohl EDWARDIAN U.3720L User manual

Rohl

Rohl U.4744 User manual

Popular Plumbing Product manuals by other brands

Moen

Moen SANI-STREAM 8797 manual

Grohe

Grohe Allure Brilliant 19 784 manual

Cistermiser

Cistermiser Easyflush EVO 1.5 manual

Kohler

Kohler Triton Rite-Temp K-T6910-2A installation guide

BEMIS

BEMIS FNOTAB100 Installation instruction

Hans Grohe

Hans Grohe ShowerTablet Select 700 13184000 Instructions for use/assembly instructions

Akw

Akw Stone Wash Basin Installation instructions manual

Enlighten Sauna

Enlighten Sauna Rustic-4 user manual

Moen

Moen ShowHouse S244 Series quick start guide

Sanela

Sanela SLWN 08 Mounting instructions

Franke

Franke 7612982239618 operating instructions

Heritage Bathrooms

Heritage Bathrooms Granley Deco PGDW02 Fitting Instructions & Contents List

Tres

Tres TOUCH-TRES 1.61.445 instructions

STIEBEL ELTRON

STIEBEL ELTRON WS-1 Operation and installation

Miomare

Miomare HG00383A manual

BELLOSTA

BELLOSTA revivre 6521/CR1 quick start guide

American Standard

American Standard Heritage Amarilis 7298.229 parts list

BorMann

BorMann Elite BTW5024 quick start guide