①②③④⑤⑥⑦⑧ ⑨

Upper roller

(embed) Lower pivot Stopper block Striker Spanner Fixing metal Pivot bearing

(on floor)

Center hinge

(fascia) Rail (Fascia) Rail (Embed)

2 door, main door end fixed Select either type

2 1 1 1 1 1 1 3

4 door, main door end fixed Select either type

4 2 2 1 1 2 2

6

Trouble Check Point Remedy

Abnormal noise during

operation

Check if door touches other parts. Provide necessary space between door and adjacent objects.

Check inside of upper rail for foreign matter or

aluminum dust.

Remove dust or foreign matter.

Check rail rollers for aluminum dust. Remove the rail and pull out the roller. Then, clean the roller.

Check for loose screws retaining the upper rail. Tighten the screw.

Heavy door operation Door bottom touches the floor. Confirm that screws are not loosened. And, adjust door height. Adjust the

clearance between door bottom and floor to 16mm.

Check if door touches adjacent parts. Correct door position to avoid contact to other objects.

Adjust position of lower guide or stopper.

Check if door is warped. Use the door without warp.

Door does not move. Check rail retaining screws for looseness. Roller touches the screw.

Retighten screws to free the roller.

Door starts to move. Check the upper rail if it is set horizontally. Using a level gauge, reset upper rail horizontally.

■TROUBLESHOOTING

OPTIONAL PARTS (SOLD SEPARATELY)

No. Part Name

Dimensional Drawing

Specifications

1

Door end holder

pin

Order code:250-017-173

Part No.:FD30-FTF

●Material Polyamide/Steel

●Finish Natural

/Colored chromating

●Accessory screw

Countersunk tapping screw 3×16

Countersunk tapping screw 3.5×16

No. Part Name

Dimensional Drawing

Specifications

2

Door end holder

(magnetic)

Order code:250-017-171

Part No.:FD30-FMF

●Material Polycarbonate

/ Neodymium

●Finish Dark brown

●Accessory screw

Flanged round head wood screw 3.1×16

Countersunk tapping screw 3.5×16

Thank you very much for selecting FD30-F CEILING MOUNT, FOLDING

DOOR SYSTEM.Before starting installation, please read this installation

manual thoroughly to install the door correctly. Improper installation

may result in injury. To prevent such accident, please follow instructions

described in this manual. After installing the door, leave this manual

to the owner so that the owner is able to use this manual to check the

door any time. The door system will be upgraded/improved without

announcement, for change in dimensions or specifications, please

confirm with delivered door system parts.

symbol denotes “warning” and ”caution” during work or operation. symbol

denotes the item which should be avoided to keep safety. symbol denotes

item which should be followed to avoid injury. If this item is not followed, injury

may be resulted.

■FOR YOUR SAFETY WORK AND OPERATION

This sliding door system should be installed by experienced person who has

correct knowledge. If the system is not installed correctly, the door will not operate

smoothly, and or may cause injury.

Do not try to use this product for any other purposes other than originally intended

for. Do not disassemble the components for any modifications. Do not use the

system for applications that are out of specification. Any improper use might result

in accident or injury. We do not take any responsibility for any damage, accident or

injury occurring from an improper use, application or wrong installation.

Avoid opening/closing the door with excessive force. Such operation may cause

trouble.

It is necessary to manufacture the frame having sufficient strength to endure the

weight of door and impact shocks upon opening/closing the door. The frame with

poor strength might result in improper and slower movement of the door. In the

worst case, door might drop down causing injury.

Warning: If this warning is not followed, injury or

damage of household good may be resulted.

IMPORTANT:

・

This manual is prepared to describe the installation methods

considered most safe and effective to set up and install the sliding

door system. The installation procedures or methods can be changed

to meet your working conditions or environments.

・

In this manual, the dimensions are not considering margin of error

or deformation of material. Therefore, please carry out each process

such as cutting, taking care of deformation or other changes.

・

In this installation manual, the dimension is used without consideration

of error by processing or assembly work or deformation of material

itself. In actual work such as cutting, therefore, should be carried out

considering actual work environment.

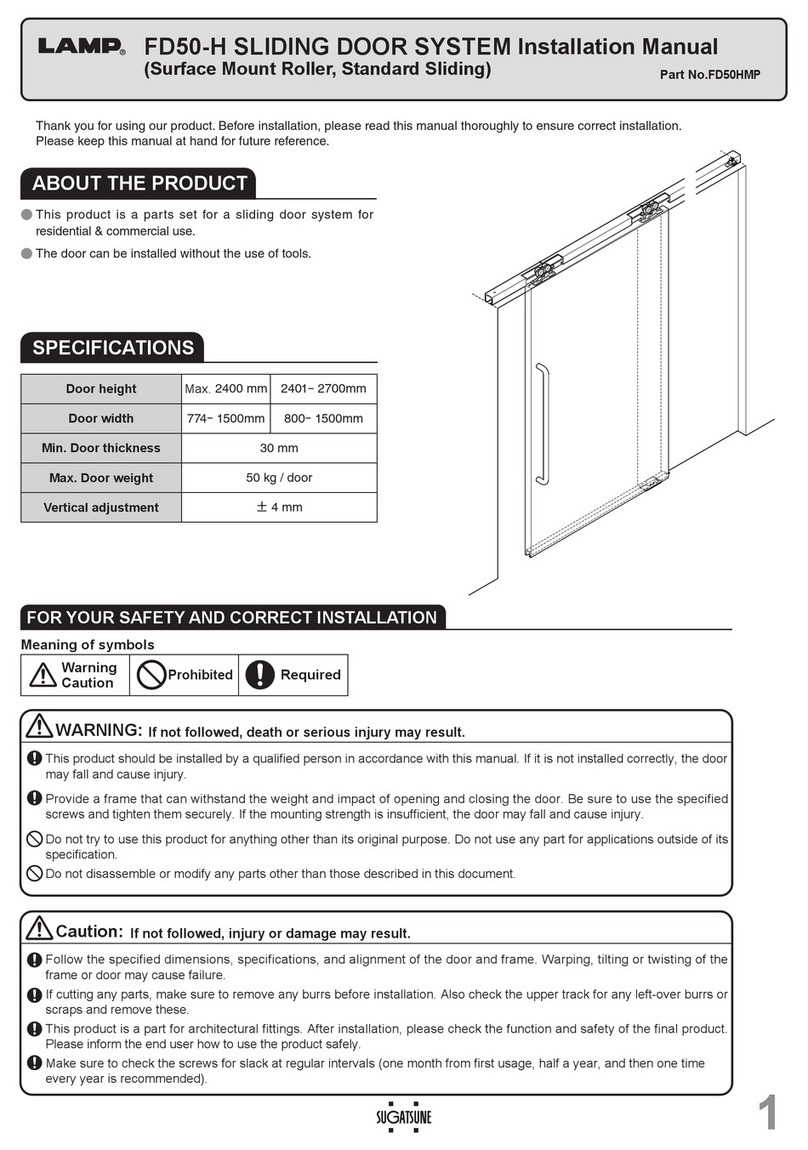

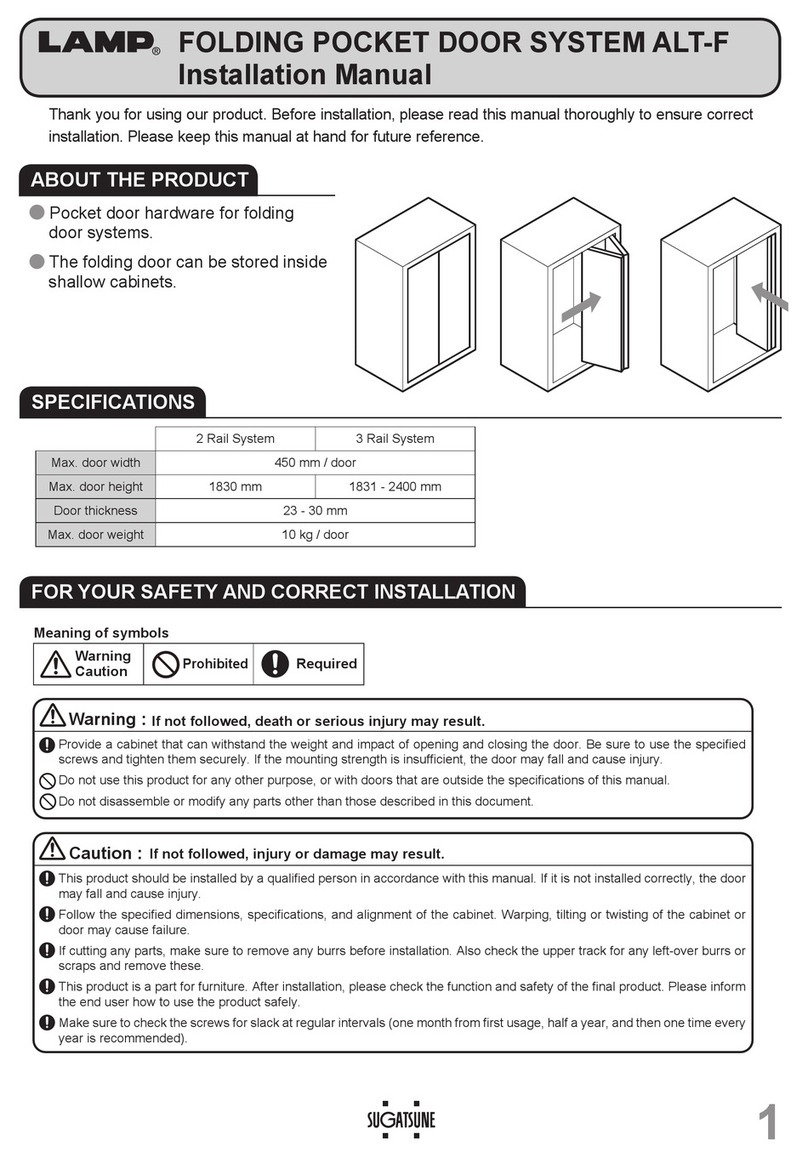

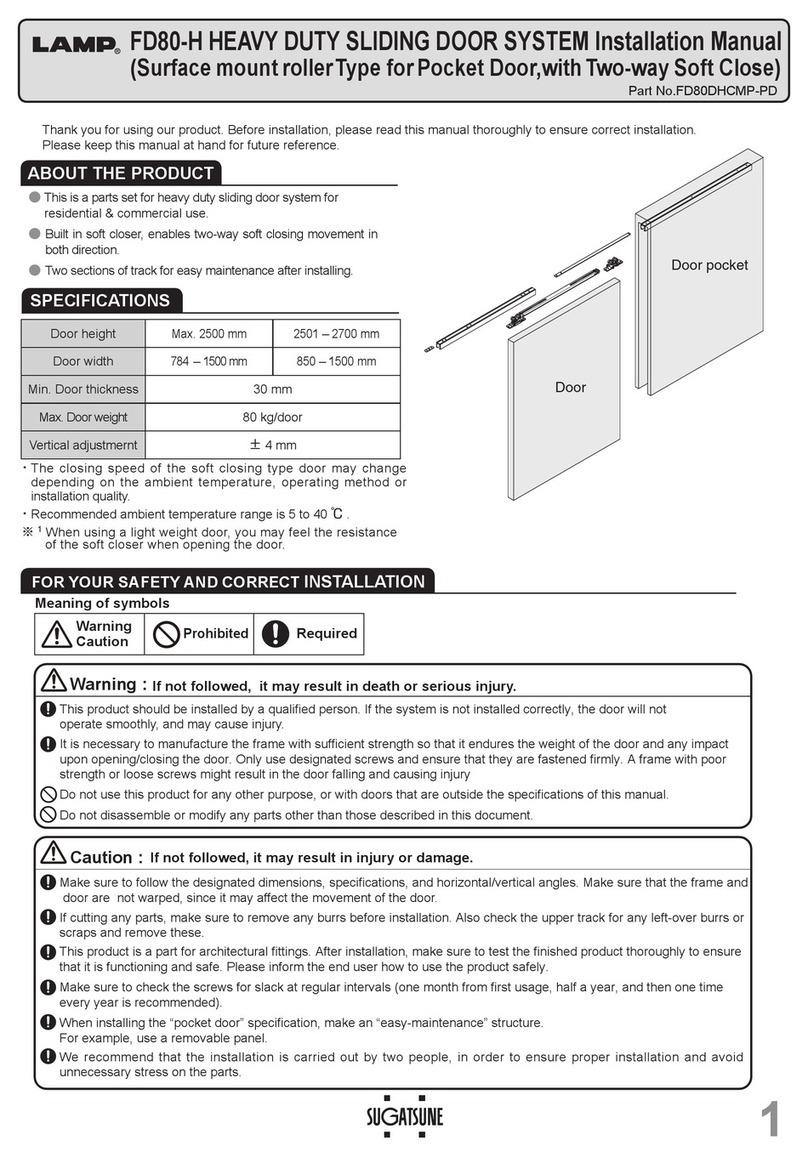

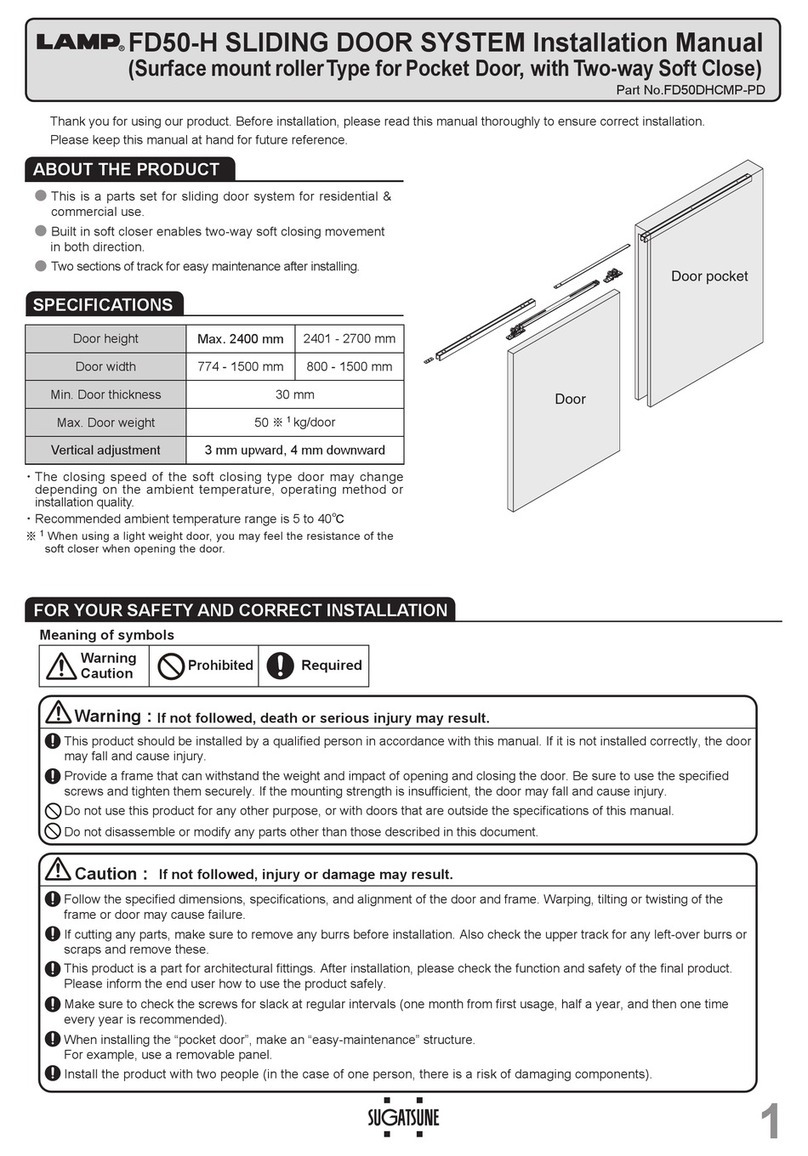

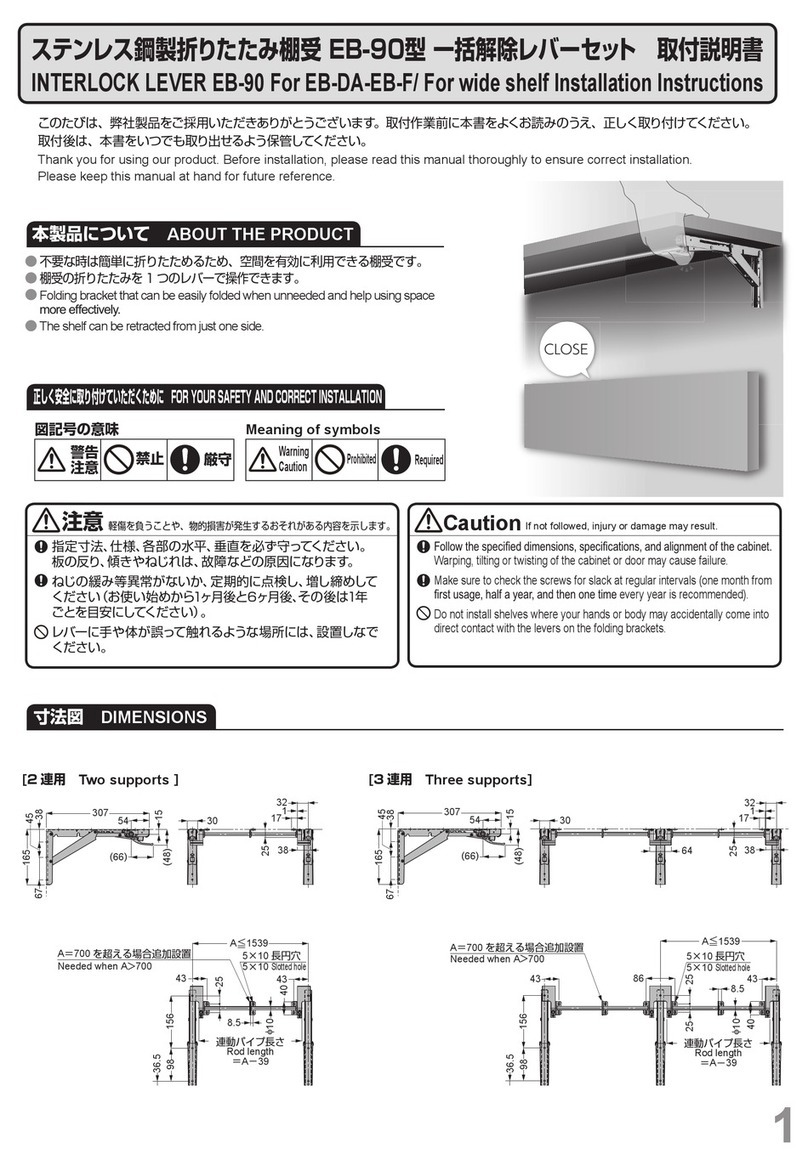

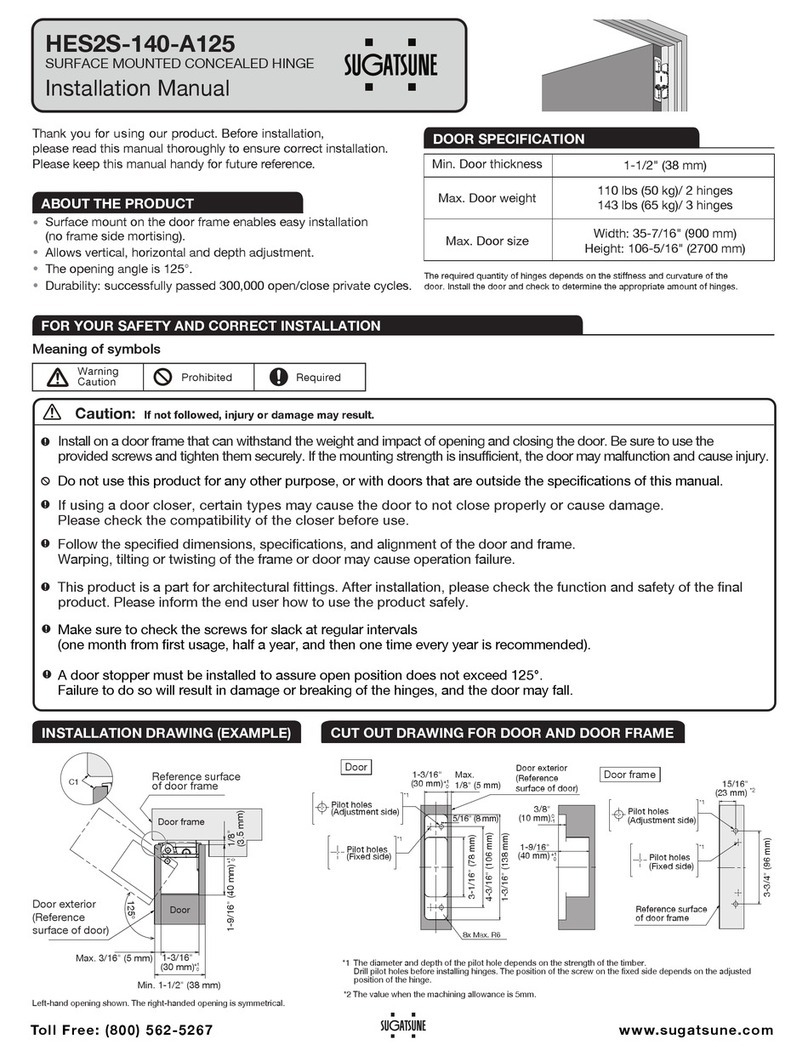

■SPECIFICATIONS

Max.Door width Min. Door thickness Max. Door height Max. Door weight Vertical adjustment

FD30-F 450mm 30mm 2400mm 15kg/door 3mm upward

As optional parts, upper roller cap, door end rolling stopper, etc. are offered. Please refer Page 4 for detail.

■ COMPONENT PARTS

1

3

1 6

8

2

7

Handle

(Optional)

9

右

上

下

左

4. Adjustment of door angle

With Philips screwdriver, adjust the

screw on center hinge.

Adjustment screw

※Adjust by hinge mount position.

Turn the screw clockwise (max: 2˚)

Turn the screw counterclockwise (max. 1˚)

178˚

179˚

Final confirmation…Confirm that all screws are securely tightened. And, confirm that all screws are used

without mistake.

右

上

下

左

FD30-F CEILING MOUNT, FOLDING DOOR SYSTEM

Installation Manual

(Main Door End Fixed Type)

Part No.

FD30UKP

ISO9001(Japan Offices and Sugatsune America) and ISO14001(Chiba Production division and Logistci center), certified.

2013.12 PRINTEDINJAPAN 0763-1

PERIDICAL INSPECTION

・Clean inside of rail.

・Check upper space and lower space of the door. If necessary, correct the space.

13.8

3

5

15.5

27.6

Rest guide

8.5

3.5

4.5 4.5

714

15

φ13

23

33

3019

φ

3.5

19〜27

72

57.9

30

13

3

0.5

30 13

2266

4

8

28

φ4 φ8 CSK

右

上

下

左

右

上

下

左

According to “Shop Drawing” ,

temporary fix stopper block.

After adjusting the stopper block to

the position where both doors keep

“V” shape during folding them slowly,

and adjust such that doors move

smoothly when closing them, fix the

adjustor block firmly.

Stopper block

PROCEDURE

3

Continued. PROCEDURE

4

Adjusting stopper block position

3.

Left-to-right adjustment (+-2mm)

With Philips screwdriver, adjust

the position of upper roller.

Left-to-right

adjustment

screw

Do not rotate the adjustment screw

exceeding adjustment limit.

Damage may be resulted.