RonI, INC 8001 Tower Point Drive Charlotte, NC 28227 U.S.A. Toll Free (866) 543-8635

Ph.:

(704)

847-2464 Fax: (704) 847-6739 Email: [email protected] Web Site: http://www.liftoflex.com Rev July 2016

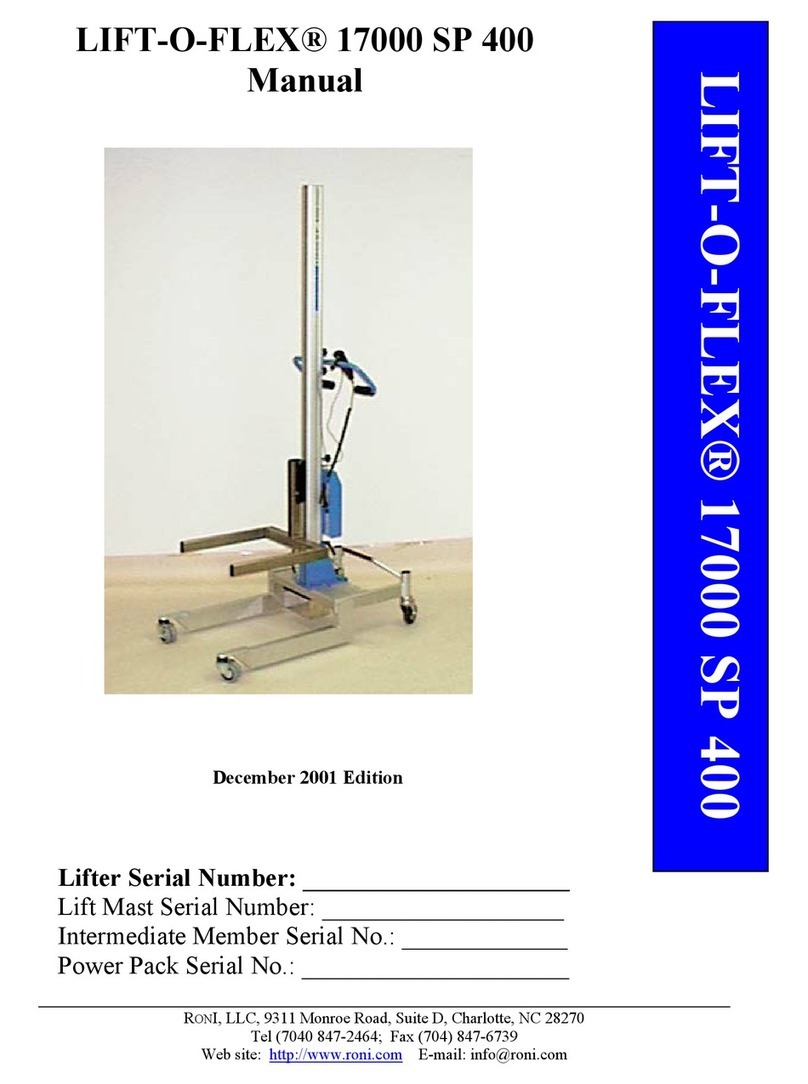

TABLE OF CONTENTS

1 Introduction................................................................................................................................................... 3

2 Safety.............................................................................................................................................................. 4

3 Warranty........................................................................................................................................................ 4

4 Product Overview.......................................................................................................................................... 5

5 Assembling instruction................................................................................................................................. 6

5.1 Assembling the Frame................................................................................................................................................................6

5.2 Assembling the End-Effector and Mast......................................................................................................................................7

5.3 Assembling the Electronic Power Pack, Handlebar and Remote Control ..................................................................................8

6 Disassembling ................................................................................................................................................ 9

7 Discarding...................................................................................................................................................... 9

8 Instruction.................................................................................................................................................... 10

8.1 Charging...................................................................................................................................................................................10

8.1.1 Battery Indicator and On/Off Switch.....................................................................................................................................11

8.2 Handle......................................................................................................................................................................................11

8.3 Mast..........................................................................................................................................................................................11

8.4 Moving.....................................................................................................................................................................................11

8.5 Directional lock........................................................................................................................................................................11

8.6 Extra lifting height....................................................................................................................................................................12

9 Maintenance................................................................................................................................................. 12

10 Trouble Shooting....................................................................................................................................... 13

11 Electrical Schematics................................................................................................................................ 14

11.1 19139B (19257S SS) 24V/16AHR and 19171B (19279 SS) 24V/32AHr Electronic Power Pack.......................................14

11.2 Electrical Schematic...............................................................................................................................................................15

12 Spare Parts................................................................................................................................................. 16

12.1 Legs (Standard Built-Single Swivel Front Wheel).................................................................................................................16

12.2 Legs (Low Built Dual Swivel Front Wheels) .........................................................................................................................17

12.3 Legs (Low Built Single Fixed Front Wheels).........................................................................................................................18

12.4 Upper Intermediate Section....................................................................................................................................................19

12.5 Lower Intermediate Section....................................................................................................................................................20

12.6 Mast........................................................................................................................................................................................21

12.7 Handle....................................................................................................................................................................................22

12.8 Lock-Upper Power Pack ........................................................................................................................................................22

12.9 Brake rod................................................................................................................................................................................22

13 Technical Specifications ........................................................................................................................... 23

14 Declaration of Conformity ....................................................................................................................... 24

15 Test Protocol.............................................................................................................................................. 25