3

6. Jumpers Setting

6.1 Setting the Sensitivity (JP2)

SA-01P has two jumpers, JP1 and JP2, to set the operation method

of the PIR. Insert a jumper to activate the desired setting.

To prevent false alarms caused by house pets or harsh environments,

two sensitivity modes are available:

Medium – for normal usage

High – for harsh environments and where the total pet’s weight

is more than 25 kg

To set the jumpers:

Medium – jumper off

High – jumper on

Normal – JP1 off

Dynamic – JP1 on

6.2 Radio Mode Jumper (JP1)

To save power, the SA-01P goes into Sleep mode after sending an

alarm. The time the device is latent is set by JP1.

Normal (always 2 minutes between alarms) – jumper off.

Dynamic (2 minutes retriggered between alarms) – jumper on.

When the Dynamic mode is set, an alarm event is sent only if there

were 2 minutes of silence prior to the current alarm. This setting is

useful for places with a high level of traffic such as factories.

6.3 Back and Cover Tamper

There are two kinds of tamper protection in this detector. The cover

tamper protects against the opening of the case and the back

tamper (optional) protects against taking the unit off the wall. To

enable the back tamper, cut the R11 wire.

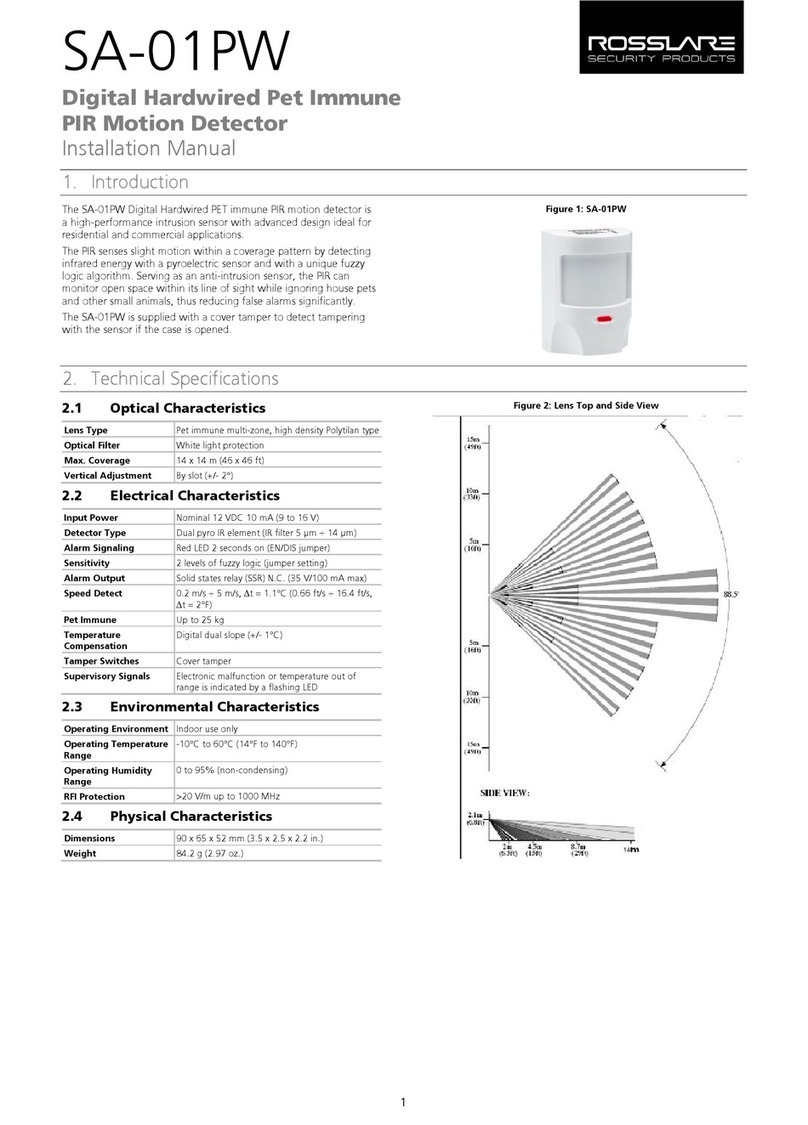

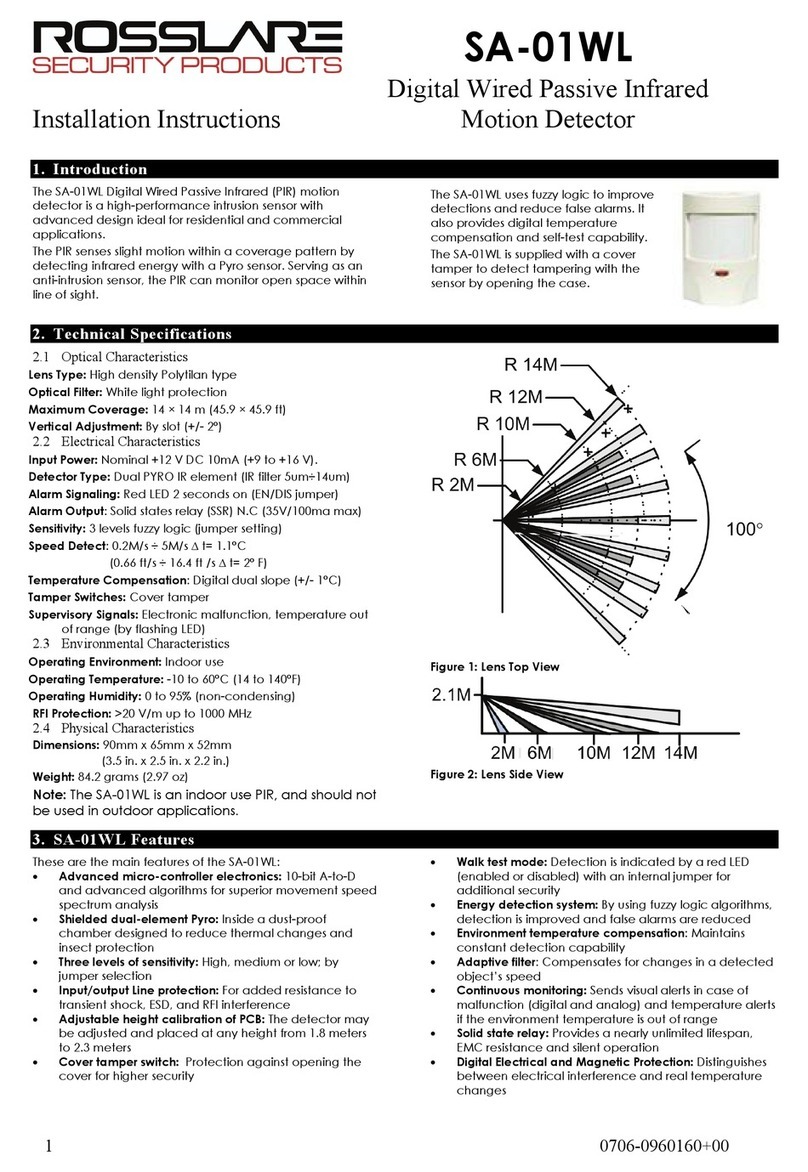

6.4 Vertical Calibration

If the SA-01P PIR is to be mounted at a height above 2.1 m or below

1.9 m, calibrate the PCB by moving the PCB up or down in the PIR

housing accordingly before fixing it (Figure 5). The calibration scale

on the PCB and the calibration marker on the PIR housing help you

achieve the optimum calibration setting.

Figure 5: Calibration Scale

The PCB calibration scale is located on the top right hand side of the

PCB (left). The calibration marker is located on the inside of the PIR

housing (right).

If mounting the PIR above 2.1 m, move the PCB (+) up in the PIR

housing so that the calibration marker is parallel to a + scale (for

example: 2). This ensures that the detection area is focused closer to

the unit.

If mounting the PIR below 1.9 m, move the PCB down (-) in the PIR

housing so that the calibration marker is parallel to a - scale (for

example: -2). This ensures that the detection area is focused further

from the unit, therefore maximizing detection range.

Either way, refrain from installing the detector higher than 2.3 m or

lower than 1.8 m since it reduces efficiency.

Figure 6: Front of PCB

7. Testing the Detector

7.1 Self Check

Perform a self check by pressing the pipe light for less than 3 seconds.

7.2 Walk Test

Evaluate the performance of the detector by executing a 2-minute

Walk Test.

1. Ensure all of the settings in the PIR are adjusted as necessary for

the location according to the installation instructions above, and

that the PIR case is closed and the locking screw is firm.

2. Apply power to the unit. The LED flashes on for 2 seconds and off

for 2 seconds for a period of 1 minute. During this time, all PIR

paths are being self tested. After the test is successful, the LED

switches off. At this point a Walk Test can be performed.

3. During the walk, test the LED flashes every time the detector

detects motion. There is a two-second wait period before the next

detection.

4. It is recommended that the installer test the detection by going

over the protected area and seeing that the detection pattern is

good.

5. The test mode can be entered for a one-minute period, by

depressing S3 from the pipe light for less than three seconds.

7.3 Radio Test

Evaluate the RF path quality by pressing the pipe light on the front of

the PIR for more than 3 seconds.

The detector transmits 10 transmissions to the control panel in 4-

second intervals. Refer to the alarm panel manual for RF quality test.

8. Enrolling the Detector

After a successful self test, you can enroll the detector to a specific

zone in the alarm system.

The easiest way to do so is to open and close the front tamper. For

specific steps to be followed for the enrollment, refer to the manual

supplied with the alarm panel.

9. Low Battery Supervision

Prior to each RF transmission, the battery voltage is sampled. If the

voltage is low for 3 consecutive transmissions, a "low battery"

message is sent with the next transmission. When the battery is low,

the LED blinks during alarm and tamper events. Once the battery

level returns to the minimum preset value, the fault transmissions

cease.