03 July 2019 Current valid documentation see: 76-10-00

Initial Issue www.flyrotax.com Page 1 of 18

Copyright - BRP-Rotax GmbH & Co KG. All rights reserved.

d06703.fm

SI-912 i-024

SI-915 i-006

SERVICE INSTRUCTION

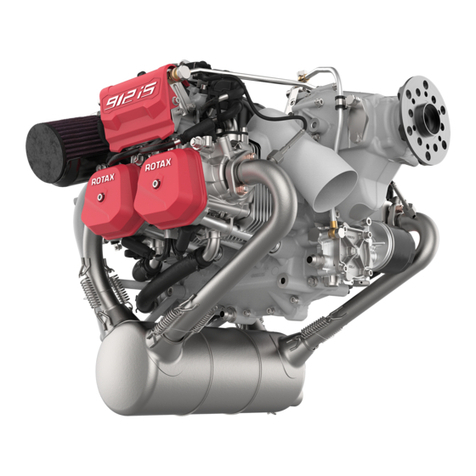

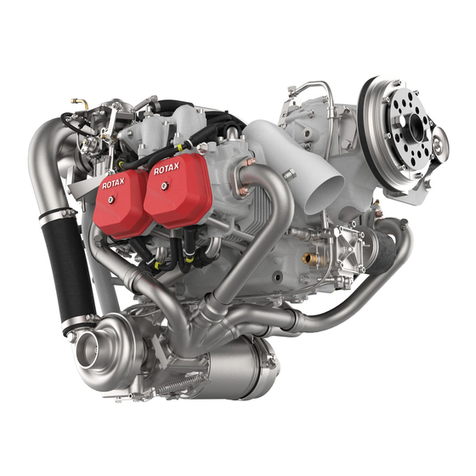

Introduction of a new connector for regulator B for ROTAX®

Engine Type 912 i, 915 i A and 915 i B (Series)

ATA System: 76-10-00 Fuse Box

1) Planning information

To obtain satisfactory results, procedures specified in this publication must be accomplished with

accepted methods in accordance with prevailing legal regulations.

BRP-Rotax GmbH & Co KG cannot accept any responsibility for the quality of work performed in

accomplishing the requirements of this publication.

1.1) Applicability

All versions of ROTAX® engine types:

NOTE: On engines with S/N higher than the ranges listed above, new style connector has

already been fitted in serial production.

NOTE: On engines with S/N lower than the ranges listed above, the regulator B or stator assy.

connections can be modified for exchange or repair of the relevant component. The

modifications on the rectifier regulator B can be performed at a maintenance, repair or

operation (MRO) event as per section 3.

NOTE: It is NOT mandatory to retrofit engines with old style regulator B and stator connector.

1.2) Concurrent ASB/SB/SI and SL

In addition to this Service Instruction the following Service Bulletin/Service Instruction must be

observed and complied with:

Service Bulletin-SB-912 i-006, title “Exchange of stator assy.“, current issue.

Service Instruction-SI-912 i-004, title “Replacement of regulator A and regulator B“, current issue.

1.3) Reason

In the course of further development and standardization, a new connector for rectifier regulator B

has been introduced. The new connector allows higher current draw.

1.4) Subject

Introduction of a new connector for regulator B for ROTAX® Engine Type 912 i, 915 i A and

915 i B (Series).

1.5) Compliance

NONE - For Information Only.

1.6) Approval

The technical content of this document is approved under the authority of DOA ref.

EASA.21J.048.

Engine type Serial number

912 i Series optional

915 iSc A from S/N 9127323

915 iS A from S/N 9132300

915 iSc B from S/N 9122524