- 2 -

E_IMHygroFlex_V3.1.doc

Contents

Overview...............................................................................................................................................3

General Description..............................................................................................................................4

Power Requirements ........................................................................................................................4

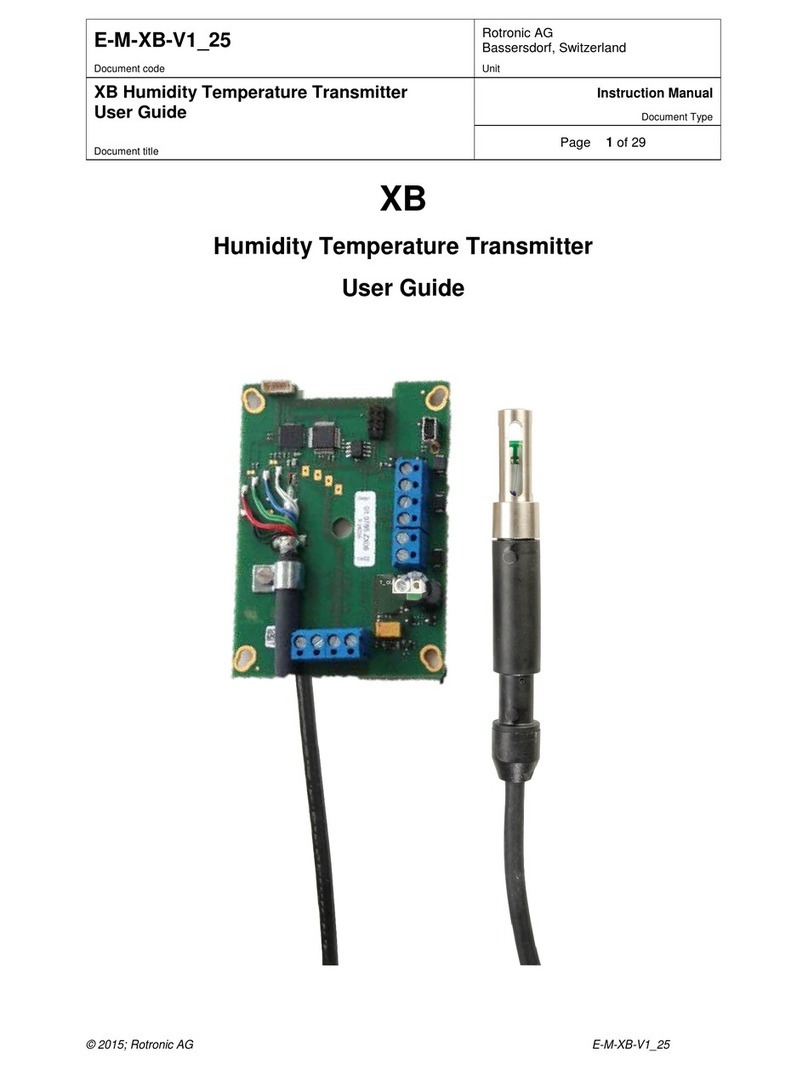

Probes and Probe Inputs..................................................................................................................5

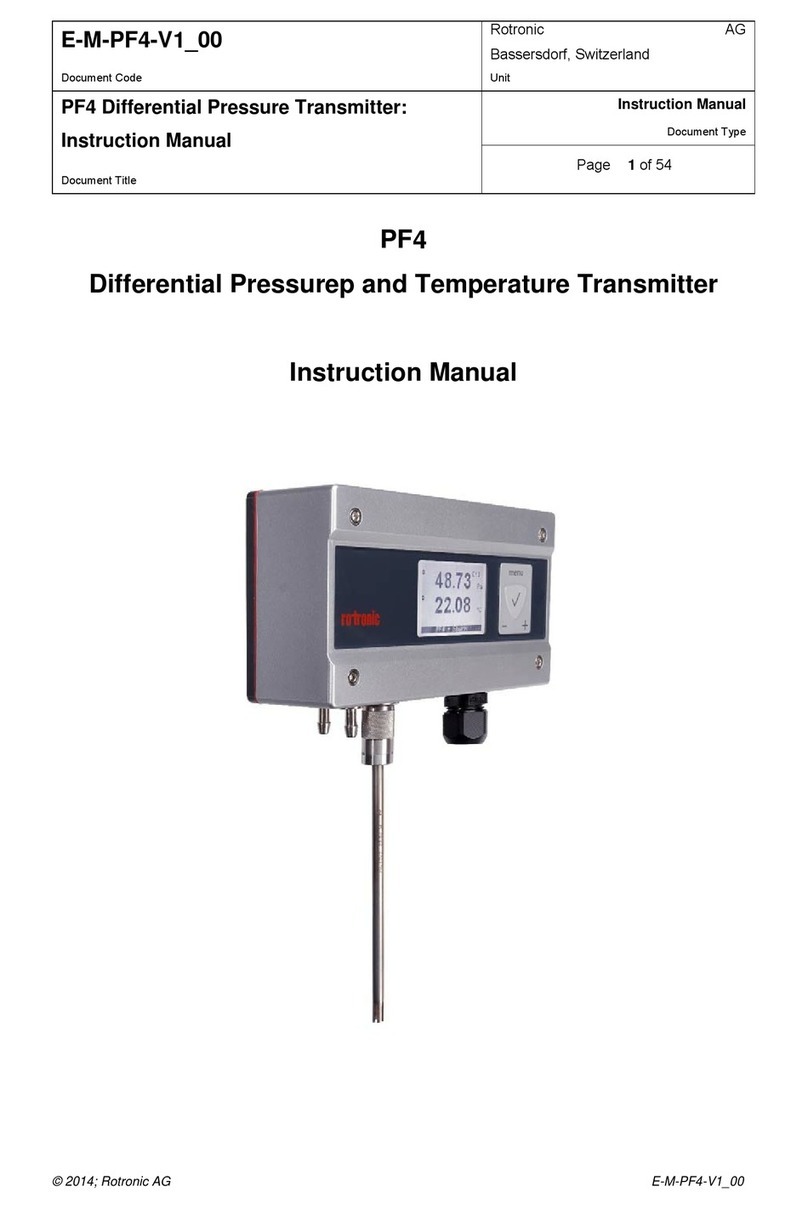

Analogue Outputs (HygroFlex 1 and HygroFlex 3) ..........................................................................7

Connection to a PC - RS232 Digital Port .........................................................................................8

HW3 Software ..................................................................................................................................8

RS485 Networking (HygroFlex 2 and HygroFlex 3) .........................................................................8

Unit System ......................................................................................................................................8

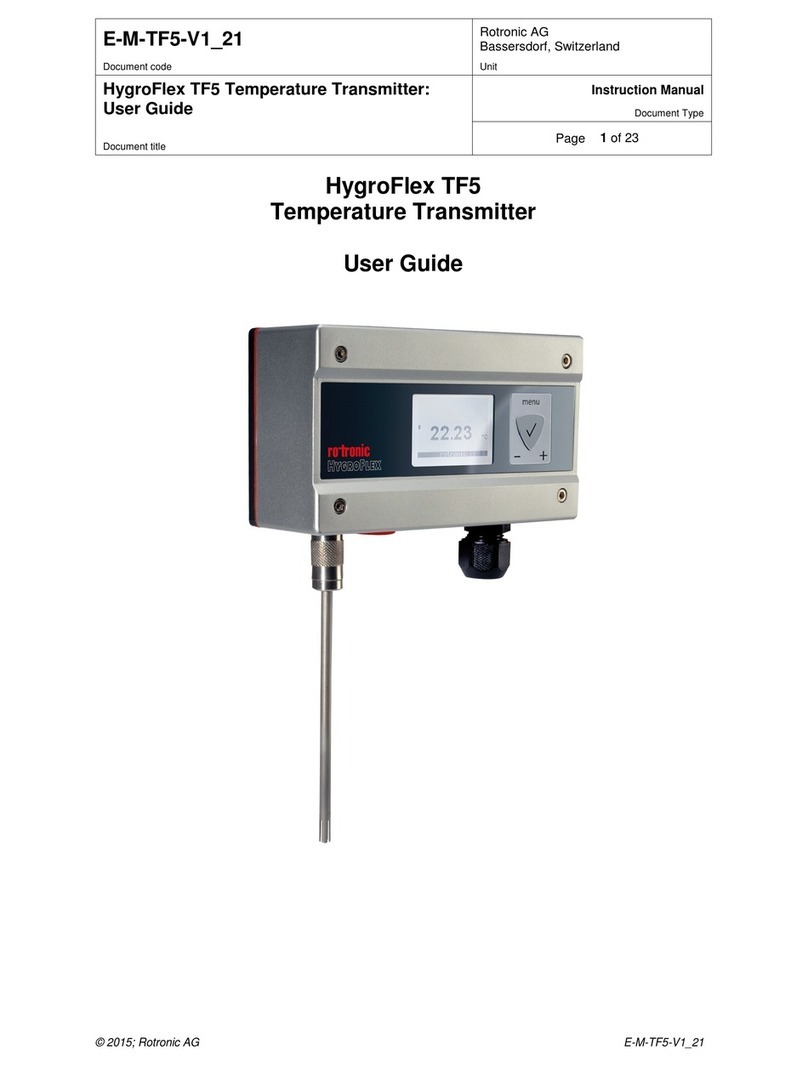

Optional Display and Keypad ...........................................................................................................9

Keypad..............................................................................................................................................9

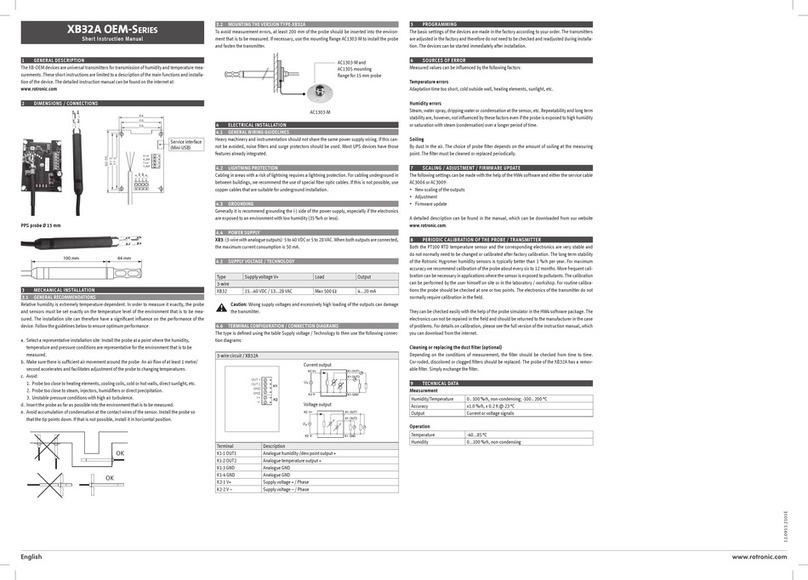

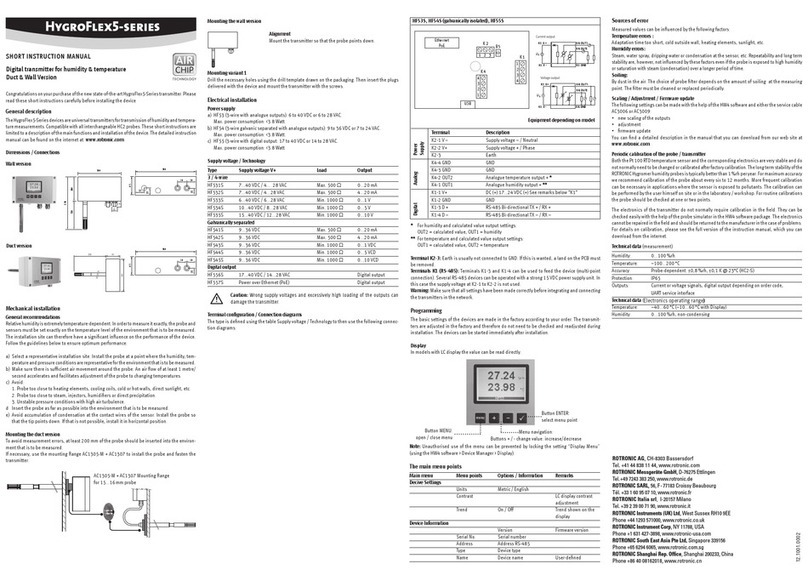

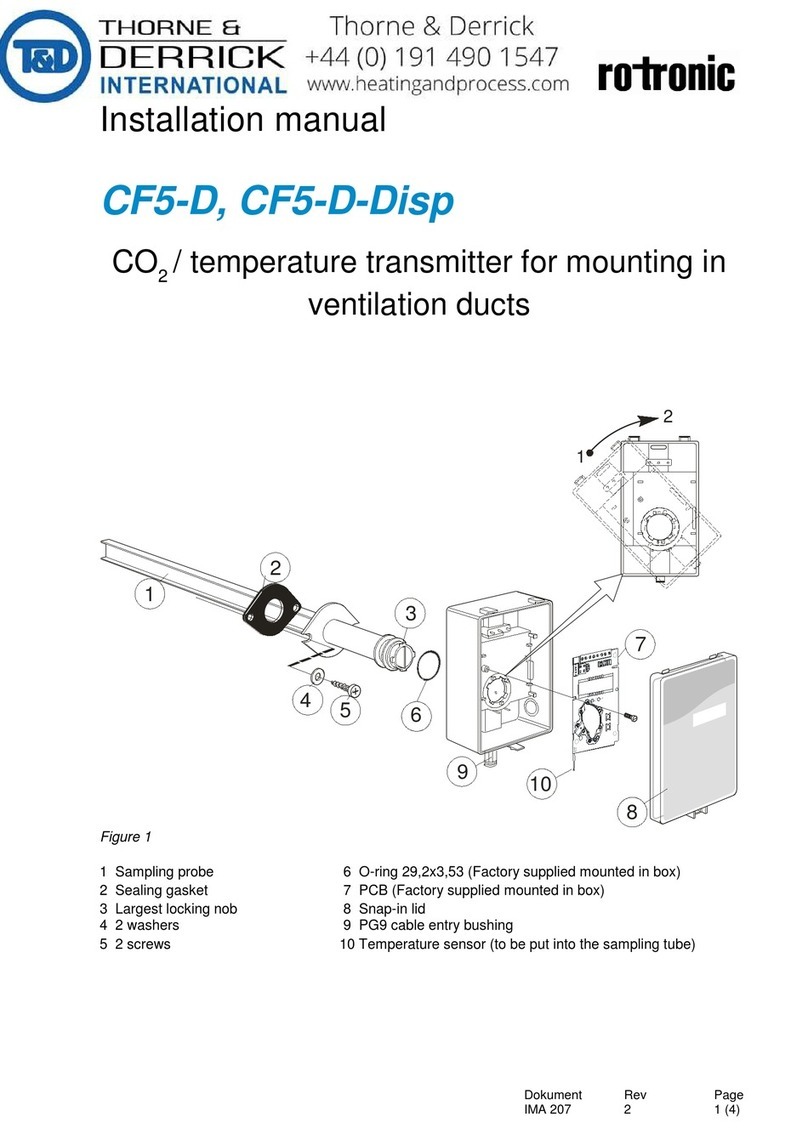

Installation ..........................................................................................................................................10

Installation of the Transmitter Enclosure ........................................................................................10

Front cover removal........................................................................................................................10

Re-attaching the ribbon cable (cover with optional Display and Keypad)......................................11

Configuration of the Analogue Outputs ..........................................................................................16

Electrical Installation Guidelines.....................................................................................................17

Serial Network Configuration (HygroFlex 2 and HygroFlex 3 only)................................................17

HygroFlex Function Menu ..................................................................................................................19

CALCULATE (HygroFlex 2 and HygroFlex 3) ................................................................................19

DISPLAY (HygroFlex 2 and HygroFlex 3 with optional LC display)...............................................20

ADJUST M.PT (2- to 4-point adjustment against a reference environment)..................................20

ADJUST 1PT (1-point adjustment against a reference environment)............................................22

ADJUST REF (1-point adjustment against a reference probe) ......................................................23

PROBE ...........................................................................................................................................23

SETTINGS......................................................................................................................................24

SYS Status .....................................................................................................................................24

OUTPUT.........................................................................................................................................24

Errors and Status Messages ..........................................................................................................25

Test Connector for the HygroPalm Indicator......................................................................................26

Display the Probe Measurements ..................................................................................................26

Functions (except ADJUST M.PT and ADJUST 1PT)....................................................................27

Functions ADJUST M.PT and ADJUST 1PT..................................................................................27

Function ADJUST REF...................................................................................................................27

Environmental Limits ..........................................................................................................................28

Maintenance .......................................................................................................................................28

On-Site Maintenance......................................................................................................................28

Factory / Metrology Lab. Maintenance ...........................................................................................28

Specifications .....................................................................................................................................29

Appendix 3: Maintenance of the ROTRONIC probes ........................................................................32

Cleaning or Replacing the Dust Filter of the Probe........................................................................32

Periodic Calibration Check of the Probes.......................................................................................32

Appendix 4: Calibration Basics...........................................................................................................33

Temperature Calibration.................................................................................................................33

Humidity Calibration .......................................................................................................................33

Appendix 5: Humidity Definitions........................................................................................................35

Appendix 6: Dew Point Accuracy .......................................................................................................37

Appendix 7: RS232 Communication Protocol ....................................................................................38

Appendix 9: Accessories for the HygroFlex .......................................................................................42

Appendix 10: Electrical Installation Guidelines...................................................................................43