T60-IO User Manual -2-

szruitech.com

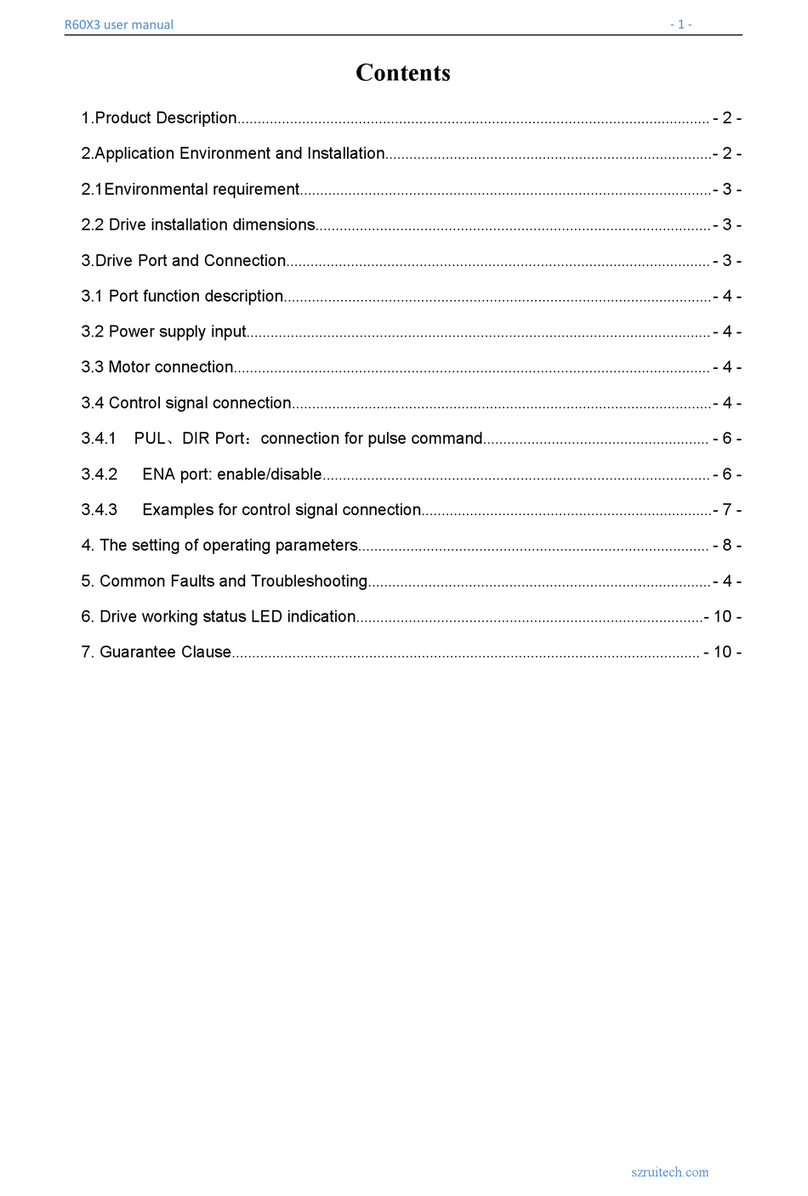

Contents

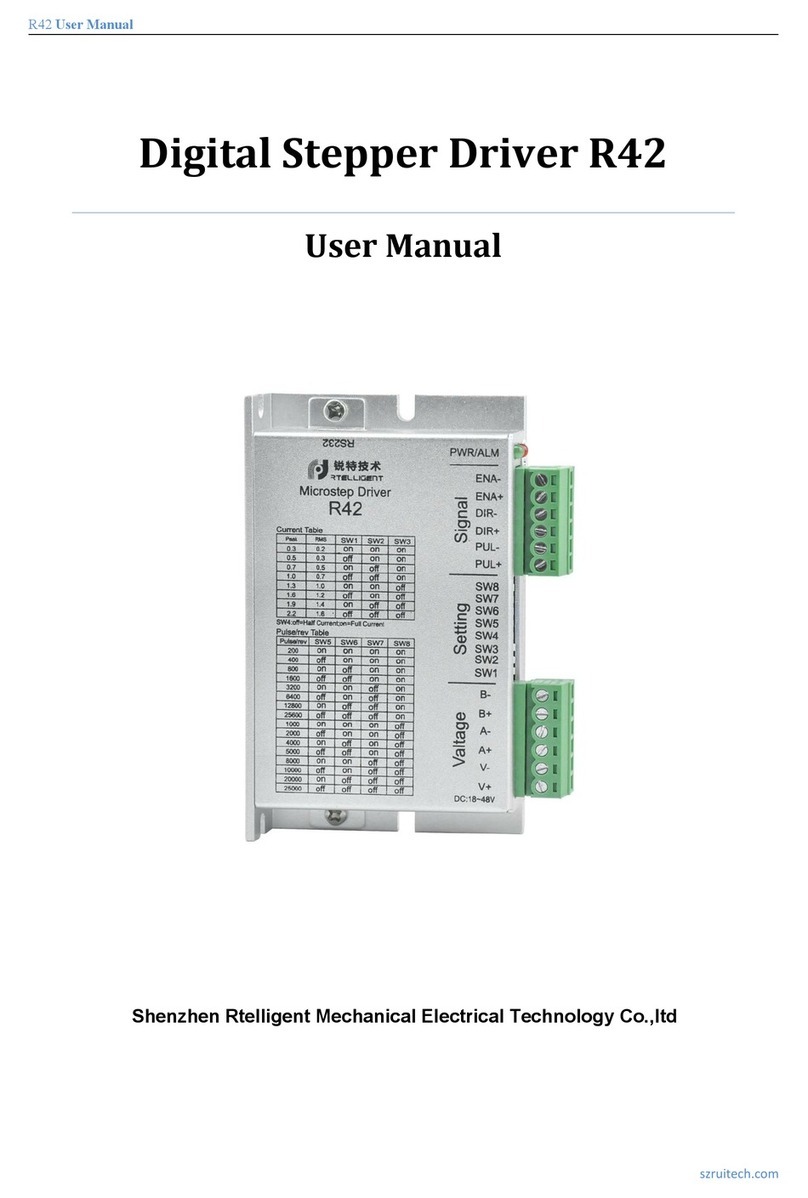

1. Product overview......................................................................................................................................... 3

2.Application environment and installation .................................................................................................. 4

2.1 Environmental requirement ..................................................................................................................4

2.2 Driver installation dimensions ..............................................................................................................5

2.3 Driver installation requirements .......................................................................................................... 5

3.Driver port and connection .......................................................................................................................... 6

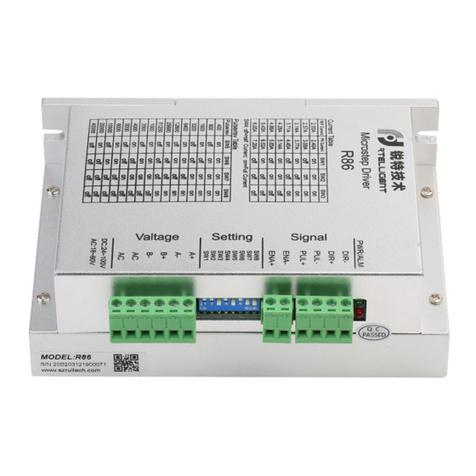

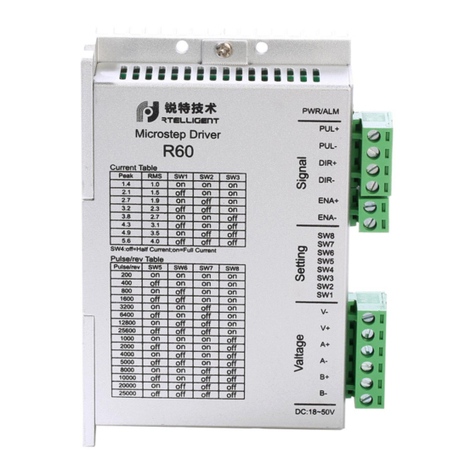

3.1 Port function description .......................................................................................................................6

3.2 Power supply input ................................................................................................................................7

3.3 Encoder connection .............................................................................................................................. 7

3.4 Motor connection ................................................................................................................................... 7

3.5 Control signal connection .....................................................................................................................8

3.5.1 PUL, DIR Port: connection for start and stop command..........................................................8

3.5.2 ENA port: enable/disable .............................................................................................................. 8

3.5.3 ALM port: used for alarm and arrival output. ............................................................................. 9

3.5.4 RS232 serial port ........................................................................................................................... 9

4. The setting of DIP switches and operating parameters ...................................................................... 10

4.1The setting of speed ............................................................................................................................ 10

4.2Motor direction selection ..................................................................................................................... 11

4.3 Open/closed loop selection ................................................................................................................11

5. Driver working status LED indication ......................................................................................................11

6. Common faults and troubleshooting.......................................................................................................12

Appendix A. Guarantee Clause ................................................................................................................... 13