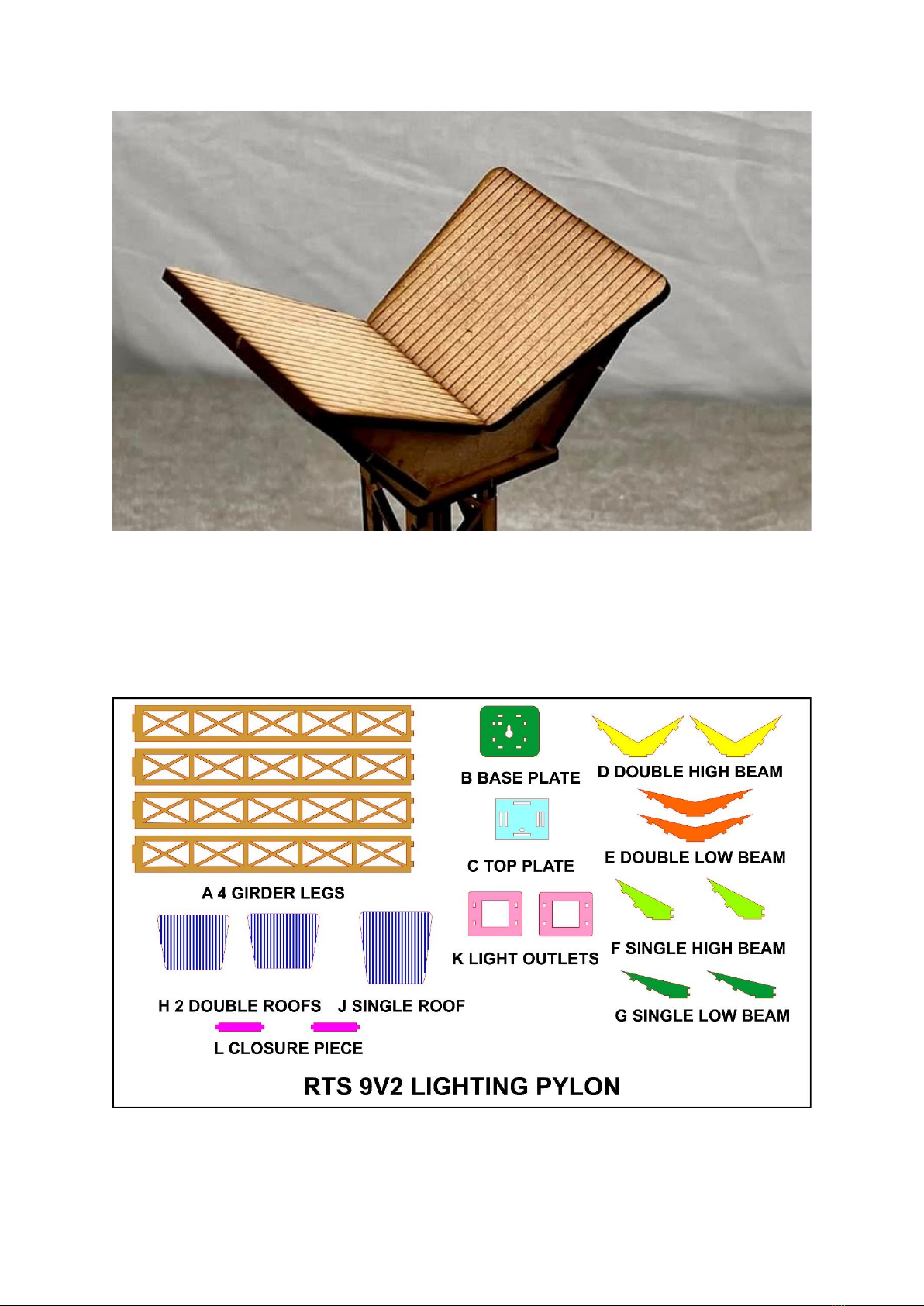

5

The pylon structure is made up of (A4 GIRDER LEGS), (B BASE PLATE) and (C

TOP PLATE). Then you can choose one of four different heads to suits your specific

needs, they are (D DOUBLE HIGH BEAM), (E DOUBLE LOW BEAM), (F SINGLE

HIGH BEAM) and (G SINGLE LOW BEAM). On all the different heads you will use

one or two of the (K LIGHT OUTLETS) and either the (H 2 DOUBLE ROOFS) or (J

SINGLE ROOF). For the single head you will also need the (L CLOSURE PIECE),

which will limit the light leak.

PREPARING THE CUT PIECES

Firstly, remove all the laser cut parts from the sheets. The sheets can be discarded.

Clean the edges of the parts if there are any tiny bits where the parts were fixed to

the sheets. This can be done with your knife or even your thumb nail.

We recommend that you start by sanding your finished product with a very light

sandpaper to ensure a smooth finish for the end product.

WORD OF ADVICE

We would strongly advise you to do a quick dry assembly before you start gluing the

laser cut parts together. Lay out all the parts on your work surface and make sure

that the parts are not upside down or mirrored. In most instances it will make no

difference, but in others it may be crucial to ensure a perfect product in the end.

PAINTING YOUR PRODUCT

We would strongly advise you to finish the product with paint or wood stain to make

them as appealing as possible. The parts should be primed (2 coats) and painted

before final assembly. Spray paint can also be used to get a very smooth finish. Oil

or water-based paint can be used and specialised paints like chalk paint can be used

to give unique finishes.

Generally, it is highly advisable to paint/spray before gluing. You may not be able to

get to the inside of the structure after it is glued together. Covering all the parts that

must not be painted or sprayed with the same colour can be a tedious process. Pre-

painting will avoid this process.

Please ensure that no paint clog a sleeve where a lug must fit in later. The

tolerances are often so tight that too thick a layer of paint may cause problems. It is

our experiences that a small foam roller instead of a brush, will produce a better

finish and far less clogging of sleeves.

Applying a base or undercoat normally makes life easier afterwards. Two coats of

primer are advisable because the MDF absorbs a lot of paint. Using a single colour

for the undercoat of all parts works quite well from personal experience. You can

choose the paint of your preference, whether it is oil or water based. Cleaning