Contents

Assembly and Operating Manual

1. Important information ...............................................................................4

1.1. Rules and regulations ......................................................................4

1.2. Guarantee and liability .....................................................................4

2. General safety instructions ......................................................................4

2.1. Intended use ....................................................................................4

2.2. Improper use ....................................................................................5

2.3. Personnel qualications ...................................................................5

2.4. Safety instructions in this manual.....................................................5

2.5. Adhere to the following instructions .................................................6

2.5.1. General instructions .........................................................................6

2.5.2. During installation.............................................................................6

2.5.3. During commissioning......................................................................6

2.5.4. During operation...............................................................................6

2.5.5. During cleaning ................................................................................6

2.5.6. During maintenance and repair........................................................6

2.5.7. Disposal ...........................................................................................6

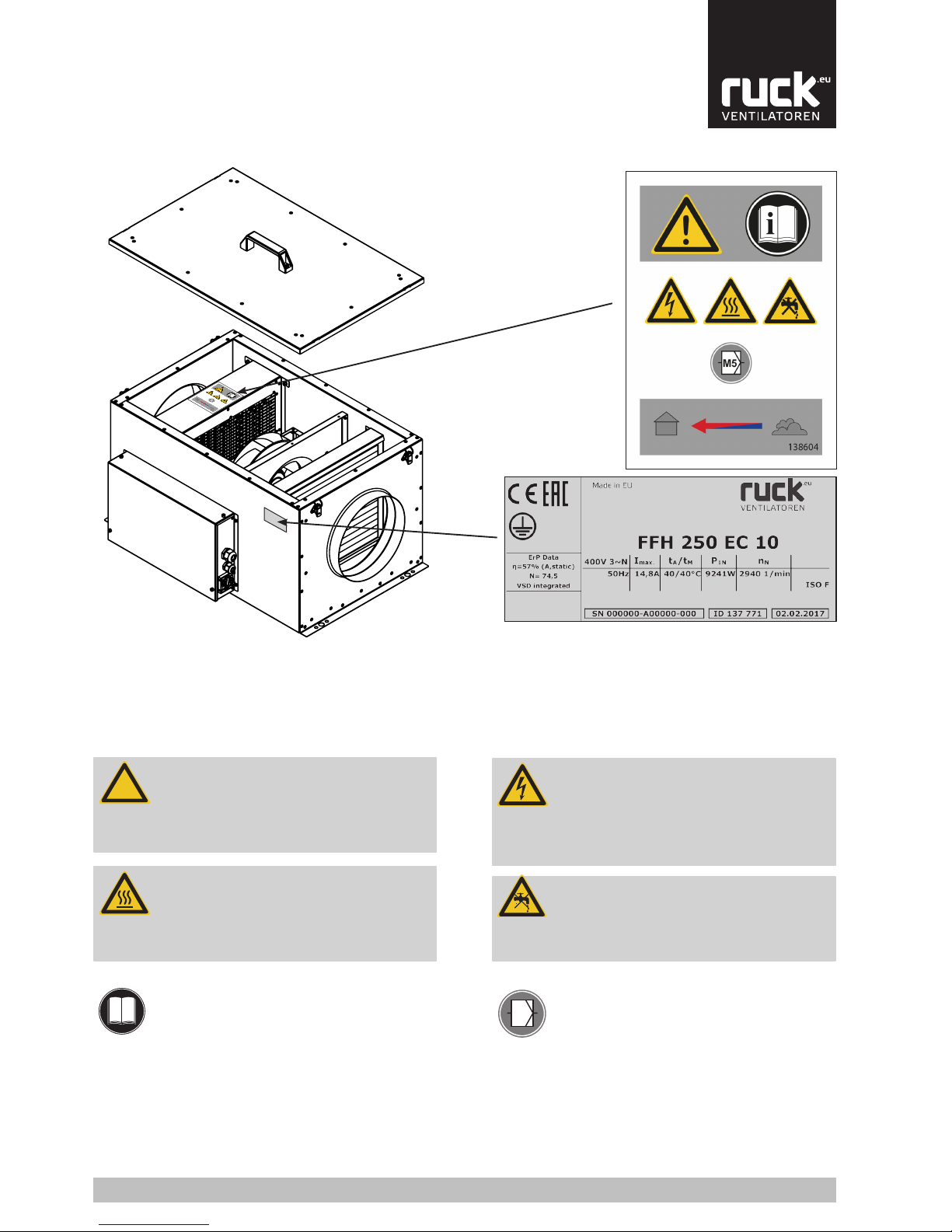

2.6. Safety labels on the product.............................................................7

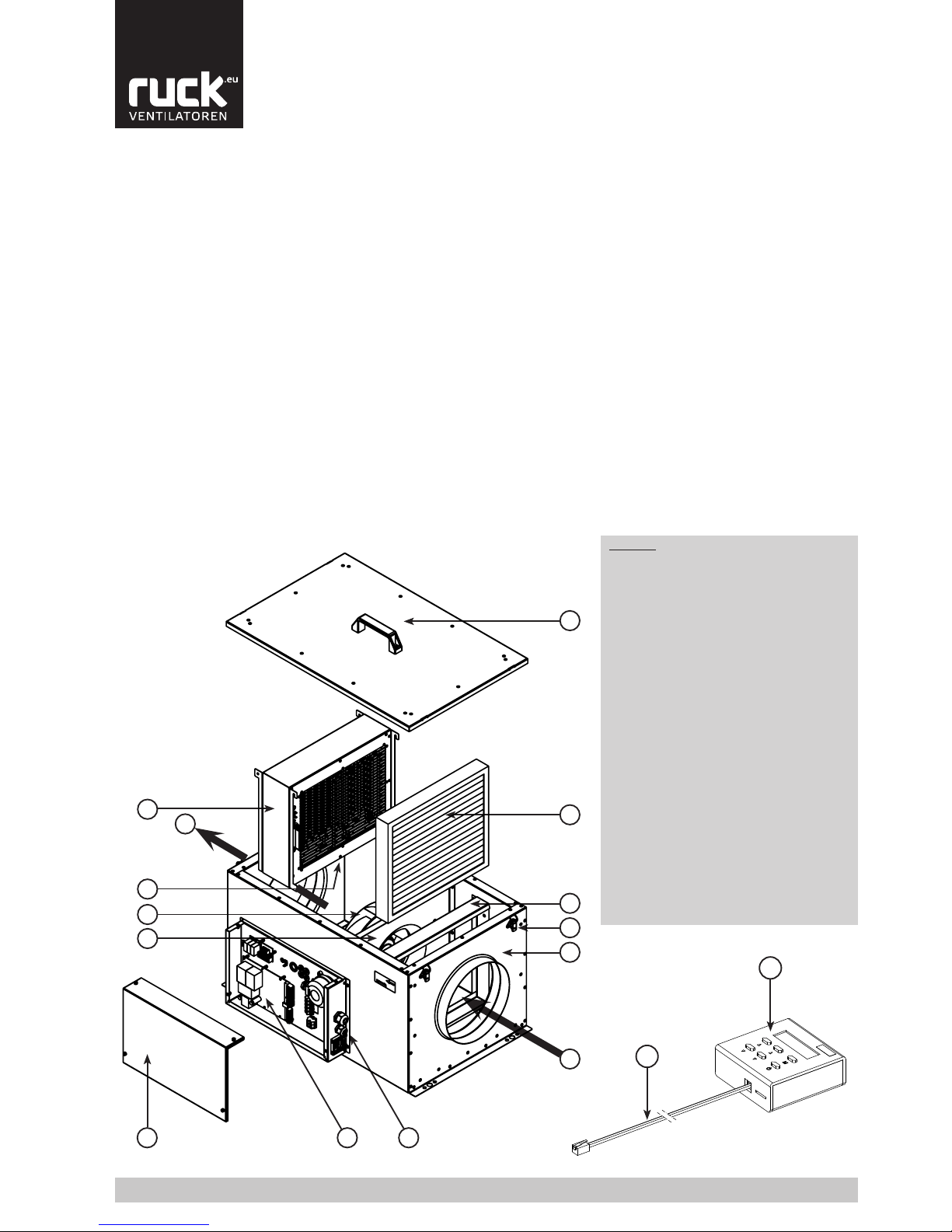

3. Delivery contents.......................................................................................7

4. Product and Performance description ....................................................8

4.1. Device description............................................................................8

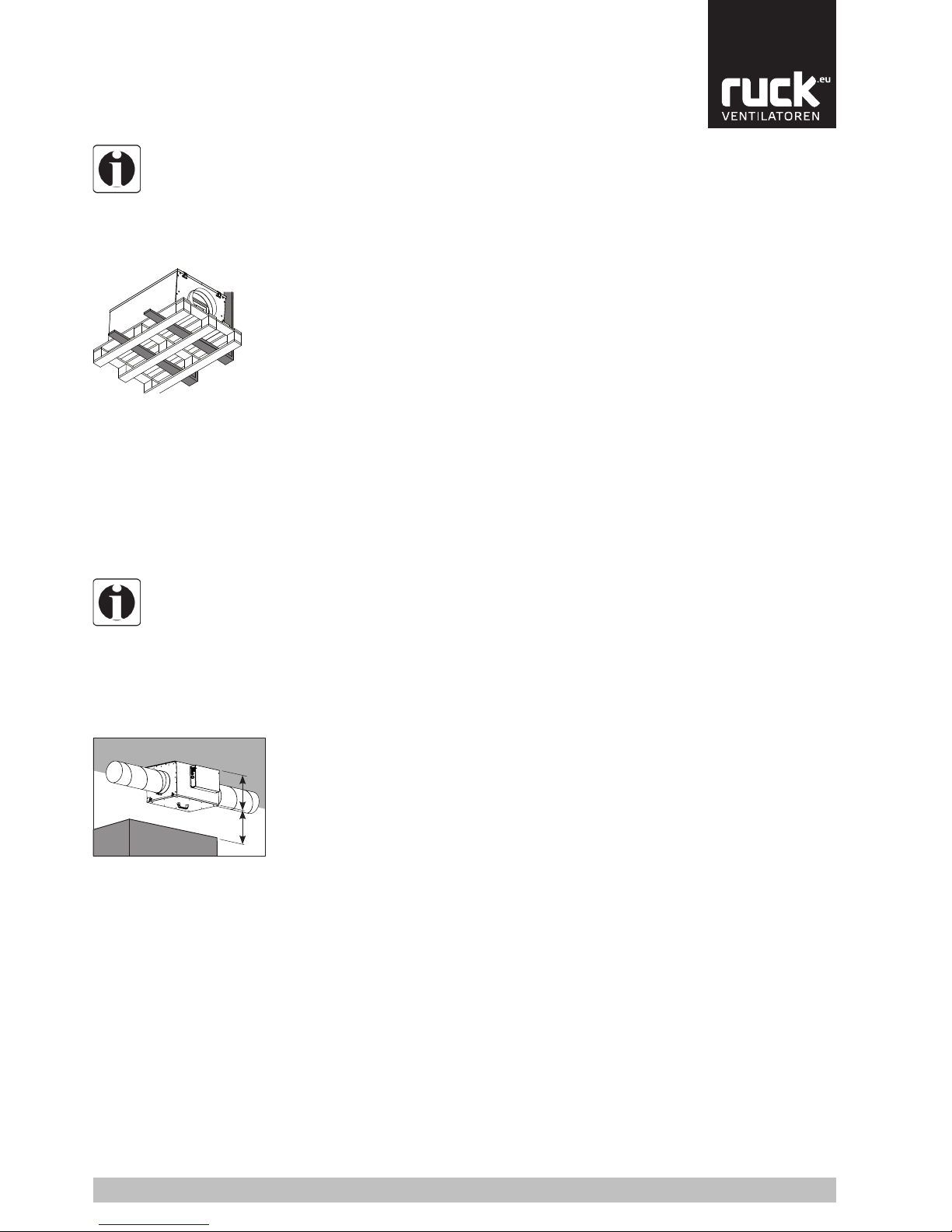

5. Transport and storage...............................................................................9

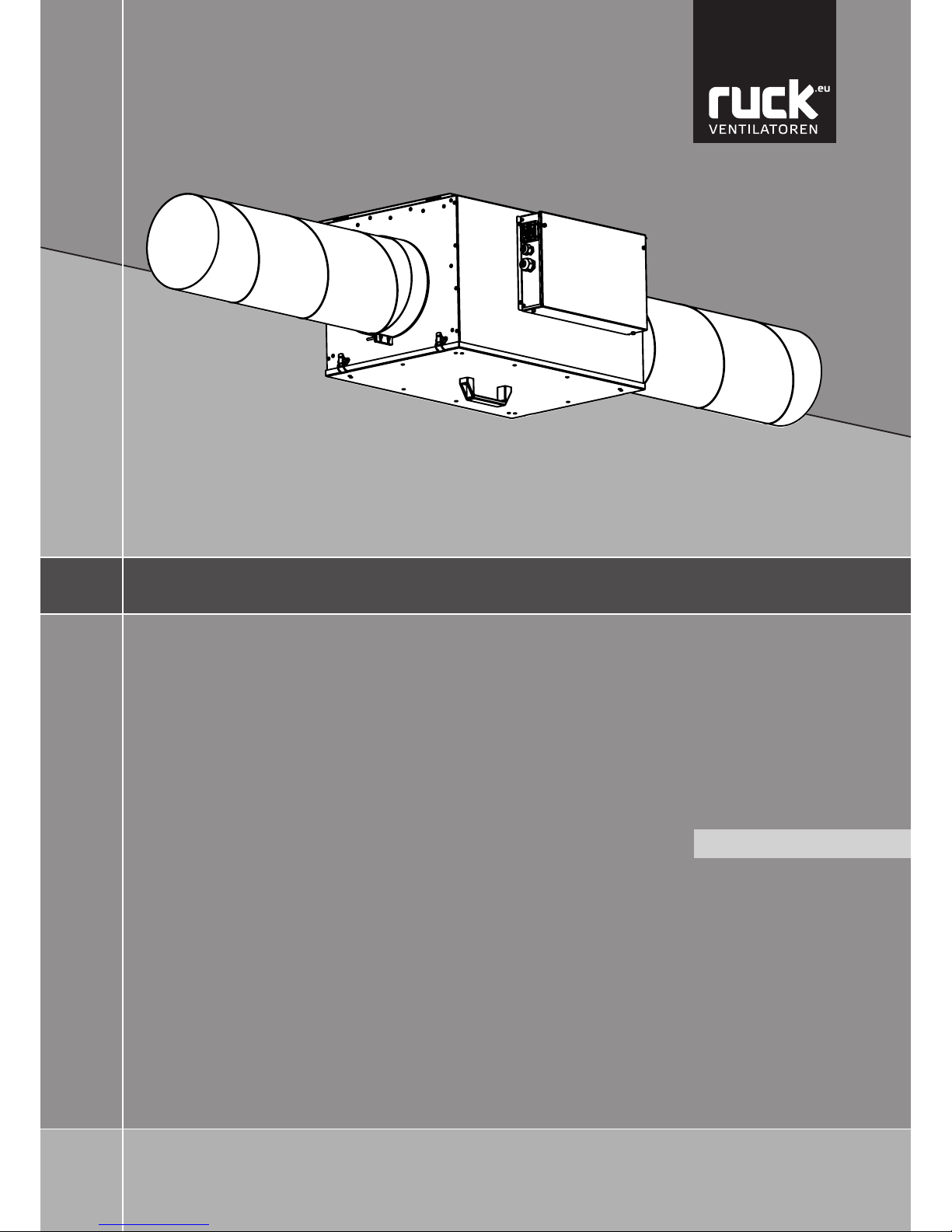

6. Assembly....................................................................................................9

6.1. Permitted installation positions.......................................................10

6.2. Operating limits ..............................................................................10

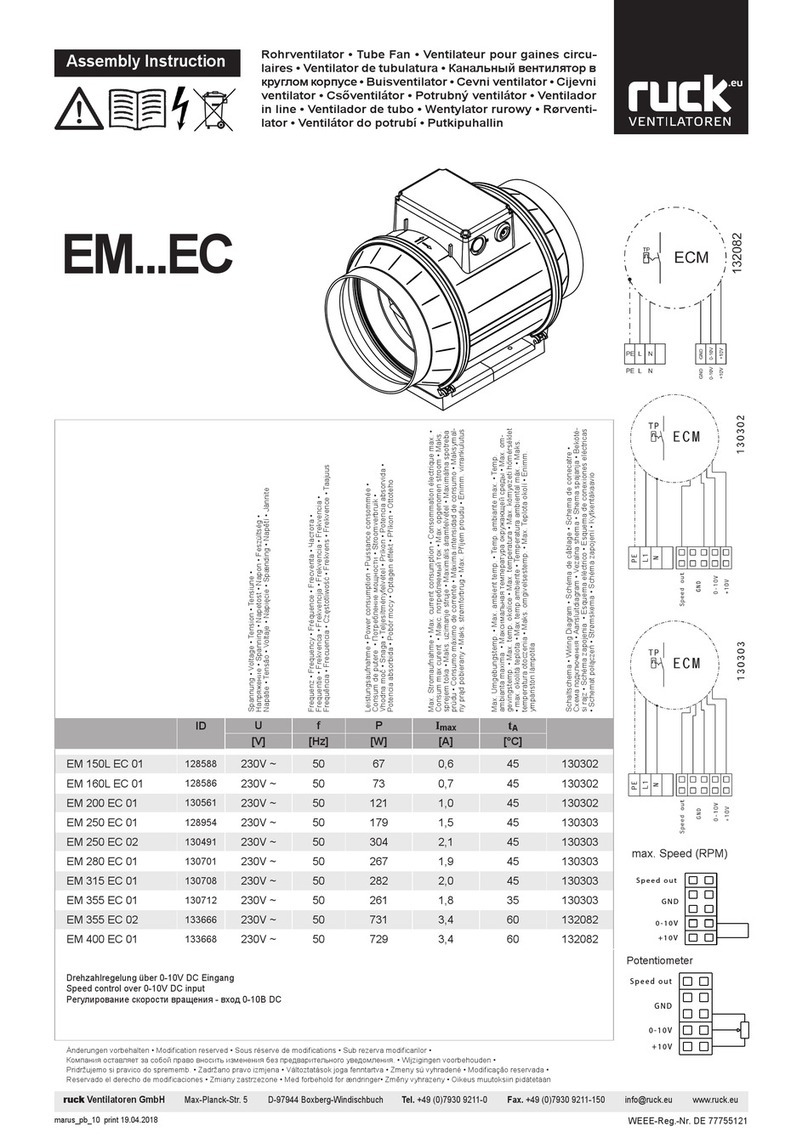

7. Electrical connection ..............................................................................10

7.1. Overcurrent protection ...................................................................11

7.2. Wiring diagrams .............................................................................12

7.3. Connection EC-extract fan .............................................................12

8. Commissioning........................................................................................13

9. Operation..................................................................................................14

9.1. Control unit.....................................................................................14

9.1.1. Adjustment of the control unit parameter .......................................15

9.2. Menu management ........................................................................16

9.3. Menu functions...............................................................................17

9.3.1. Time / Time switch..........................................................................17

9.3.2. Operating variables Menu ..............................................................18

9.3.3. Parameter settings Menu ...............................................................19

9.4. Additional functions ........................................................................20

10. Maintenance and repair ..........................................................................20

10.1. Important notes ..............................................................................20

10.2. Cleaning and care ..........................................................................21

10.3. Maintenance...................................................................................21

10.3.1. Air lter...........................................................................................21

10.3.2. Changing the battery .....................................................................22

11. Expansionandreconguration..............................................................22

12. Dismantling and disposal .......................................................................22

12.1. Disassembling the product.............................................................22

12.2. Disposal .........................................................................................22

13. Troubleshooting.......................................................................................23

13.1. Low-current fuses...........................................................................23

13.2. Fault diagnosis chart ......................................................................24

13.3. Possible operating faults. ...............................................................24

14. Technical data..........................................................................................25

15. Appendix ..................................................................................................26

15.1. List of parameters ..........................................................................26

15.2. Wiring diagrams .............................................................................27

3