Contents

Notes on the use of these operating instructions

099-008632-EW501

05.12.2019

1 Contents

1Contents..................................................................................................................................................3

2For your safety.......................................................................................................................................4

2.1 Notes on the use of these operating instructions ..........................................................................4

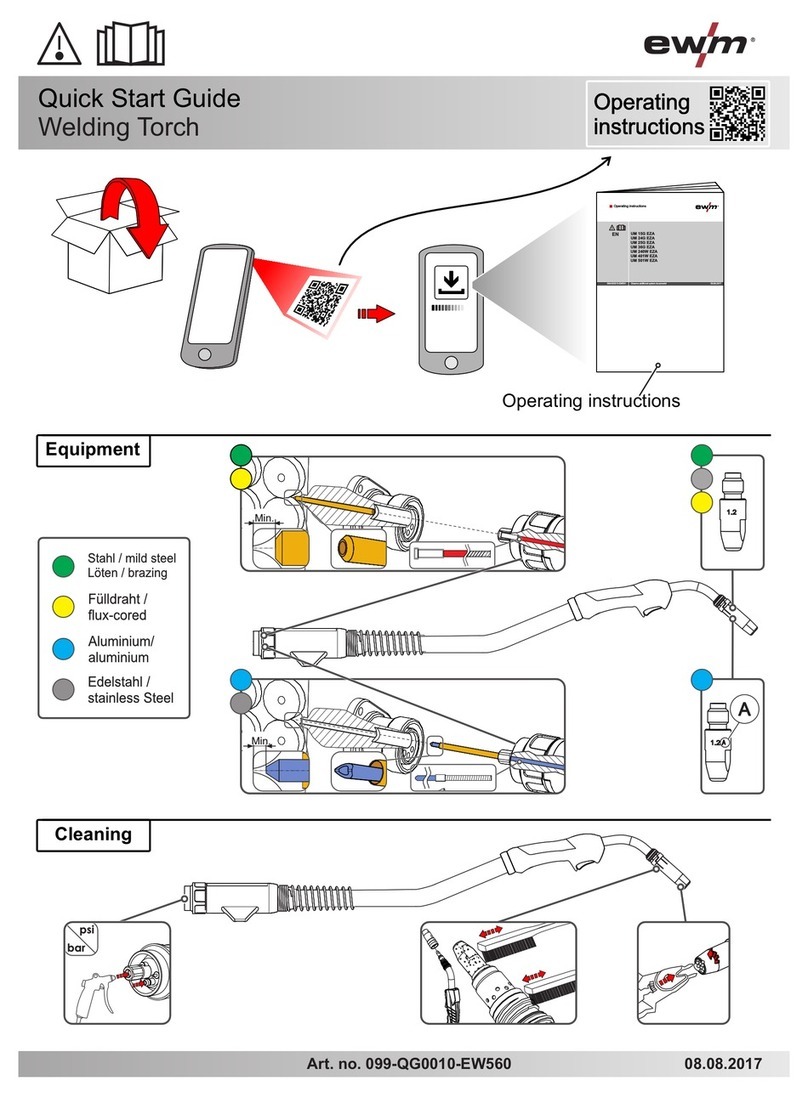

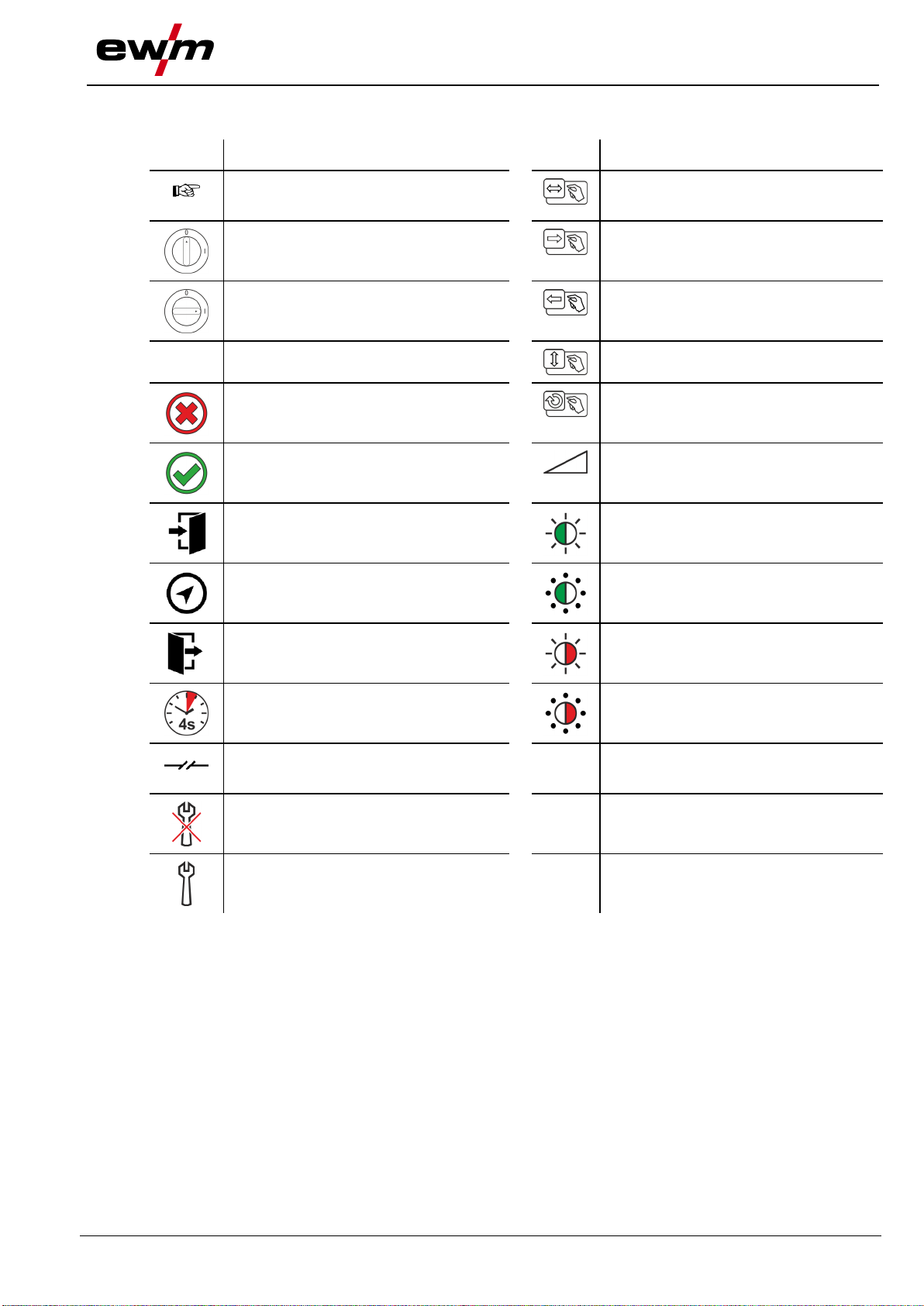

2.2 Explanation of icons.......................................................................................................................5

2.3 Part of the complete documentation..............................................................................................6

3Intended use...........................................................................................................................................7

3.1 Use and operation solely with the following machines..................................................................7

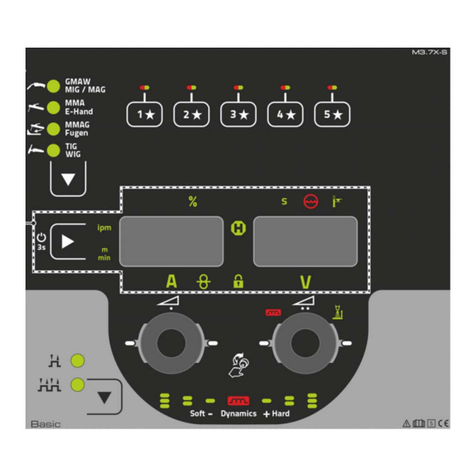

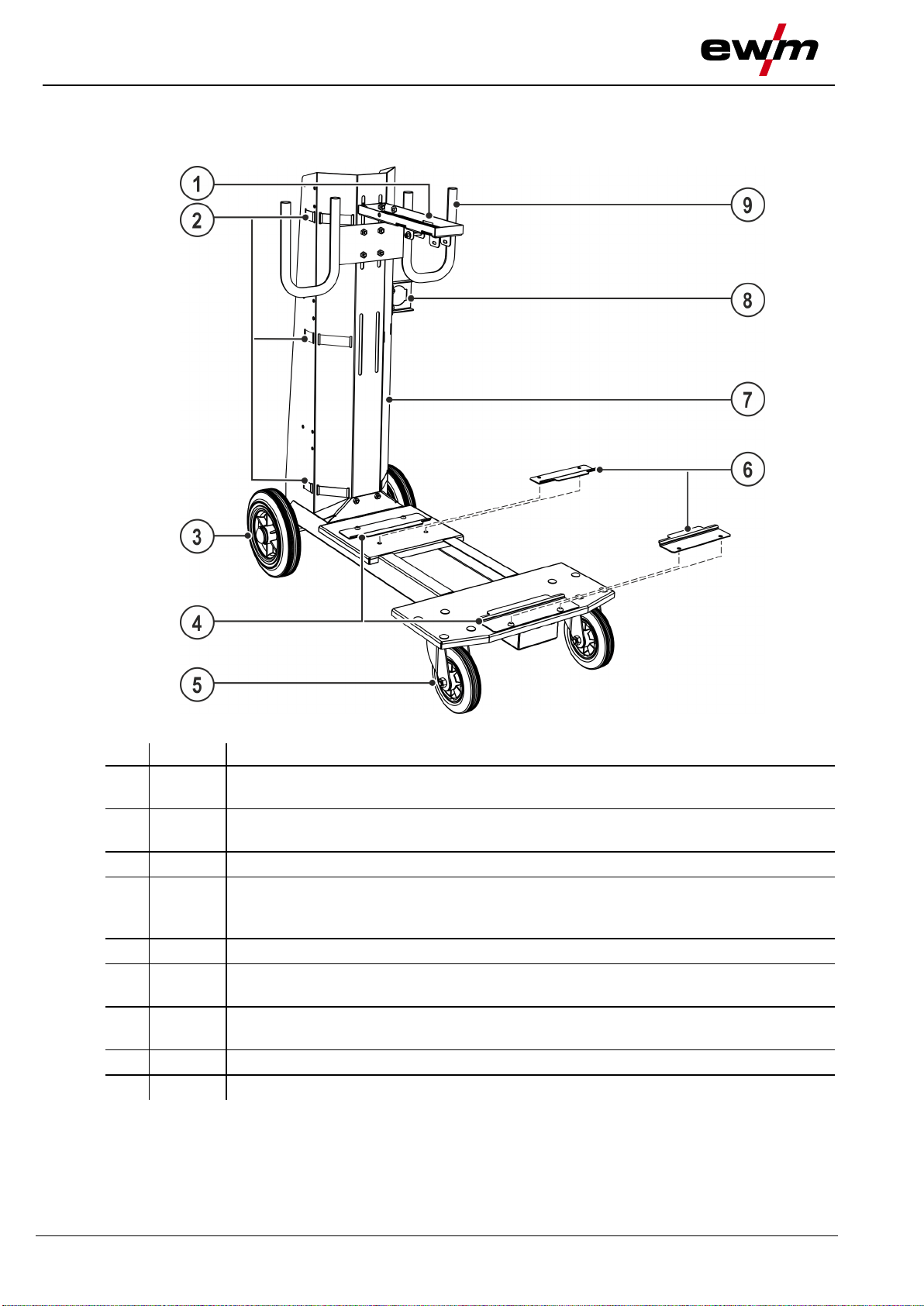

4Machine description –quick overview ................................................................................................8

4.1 Front view / side view from left ......................................................................................................8

5Design and function...............................................................................................................................9

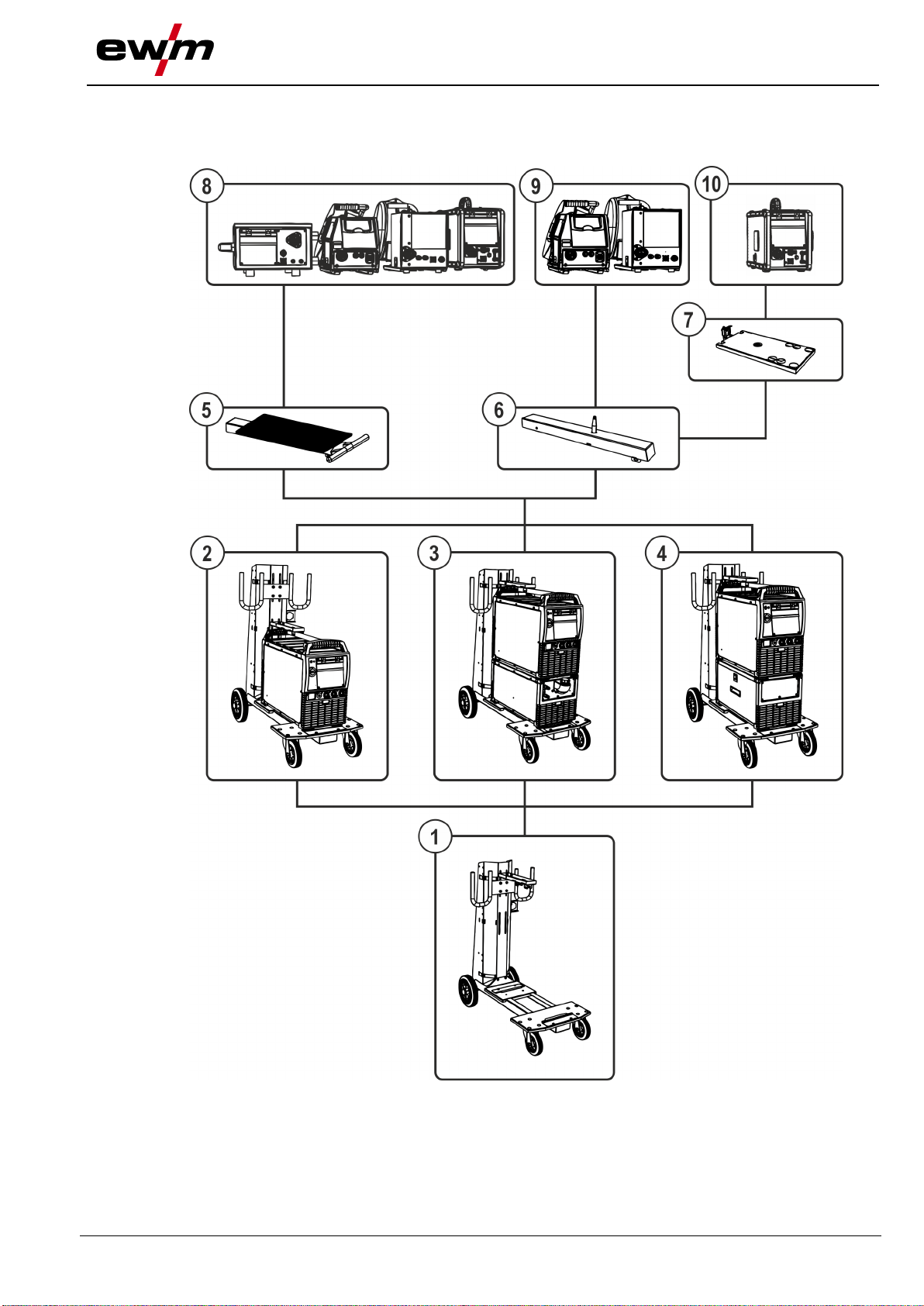

5.1 System overview............................................................................................................................9

5.2 Assembling the transport cart......................................................................................................11

5.2.1 Final assembly..............................................................................................................12

5.3 Attach the system component to the transport cart.....................................................................13

5.3.1 Intermediate hose package strain relief .......................................................................15

5.3.1.1 Locking the strain relief.................................................................................15

5.4 Securing the shielding gas cylinder.............................................................................................16

5.5 Transport and installation ............................................................................................................17

6Maintenance, care and disposal.........................................................................................................18

6.1 General........................................................................................................................................18

6.1.1 Cleaning .......................................................................................................................18

6.1.2 Dirt filter........................................................................................................................18

6.2 Maintenance work, intervals........................................................................................................19

6.2.1 Daily maintenance tasks ..............................................................................................19

6.2.2 Monthly maintenance tasks..........................................................................................19

6.2.3 Annual test (inspection and testing during operation)..................................................19

6.3 Disposing of equipment ...............................................................................................................20

7Technical data ......................................................................................................................................21

7.1 Trolly 55-5....................................................................................................................................21

8Accessories..........................................................................................................................................22

8.1 General accessories....................................................................................................................22

9Appendix...............................................................................................................................................23

9.1 Searching for a dealer .................................................................................................................23