Rugby Manufacturing SR-Series Hoist Manual

1841488E Rugby Manufacturing ToC

Table of Contents

How to Use This Manual .......................................................................... 1

Labels ..........................................................................................................................1

Reference Information .......................................................................... 2-4

Serial Number..............................................................................................................2

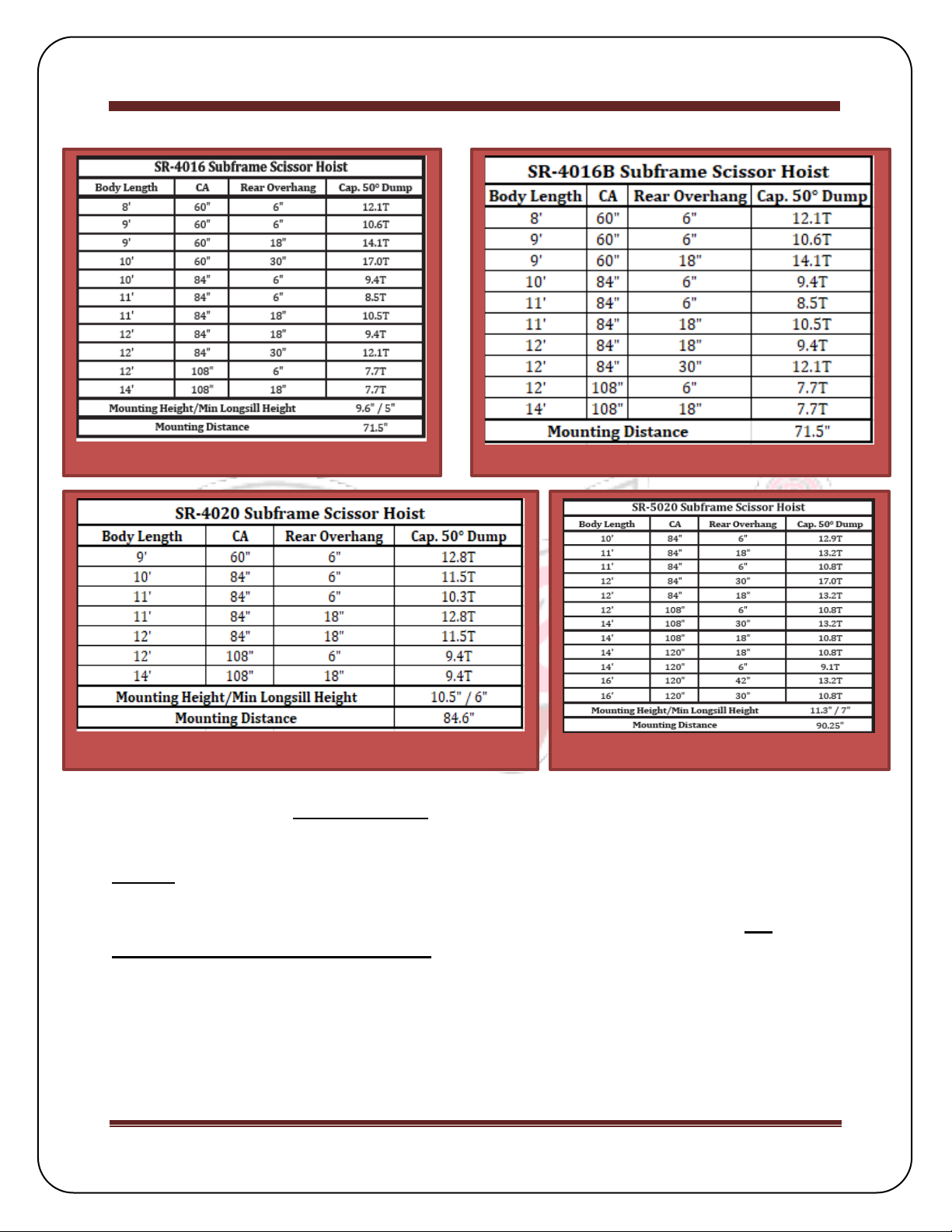

Capacity Chart.............................................................................................................3

Torque Values Chart....................................................................................................4

General Safety ...................................................................................... 4-5

Hydraulic System......................................................................................................4-5

Installation .......................................................................................... 6-15

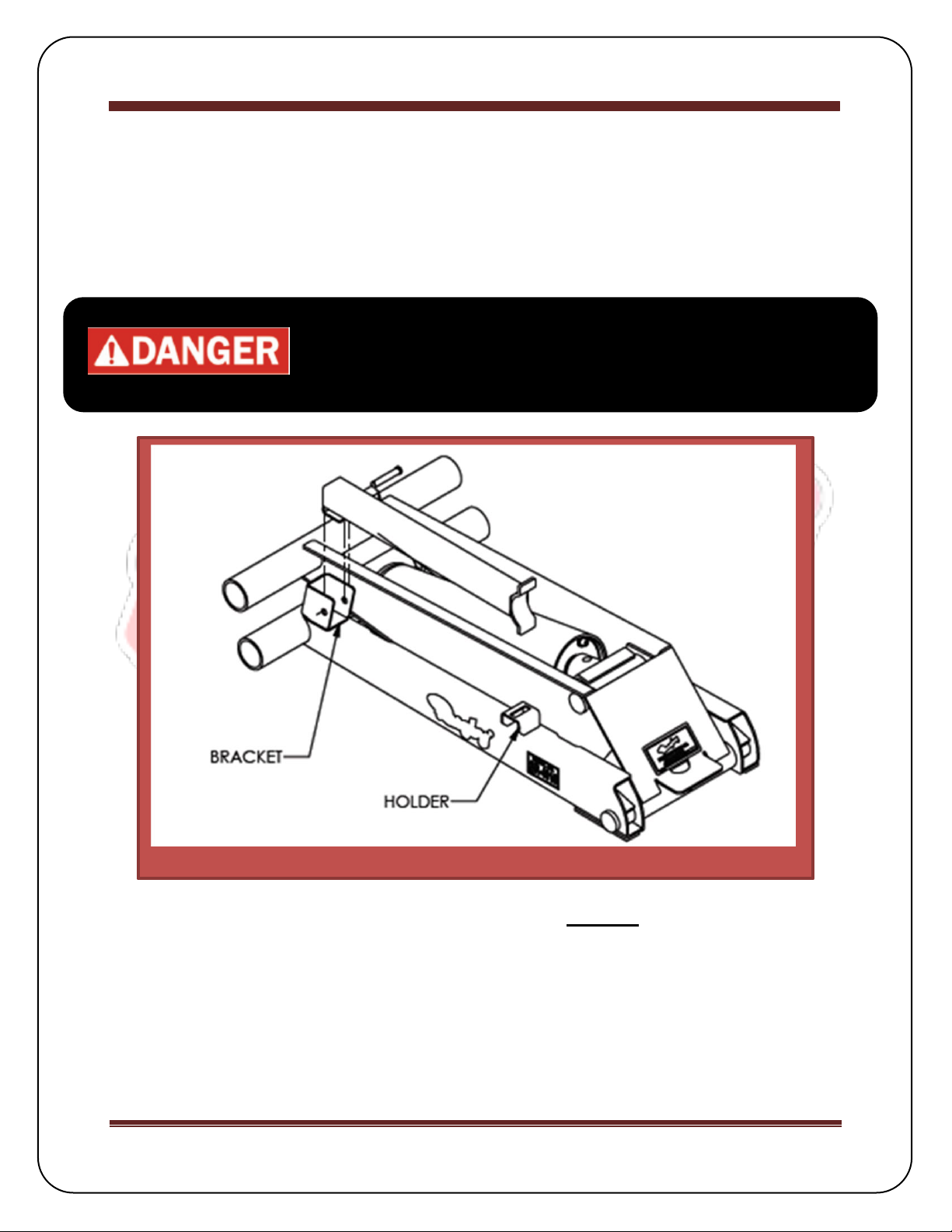

Body Prop Installation..................................................................................................6

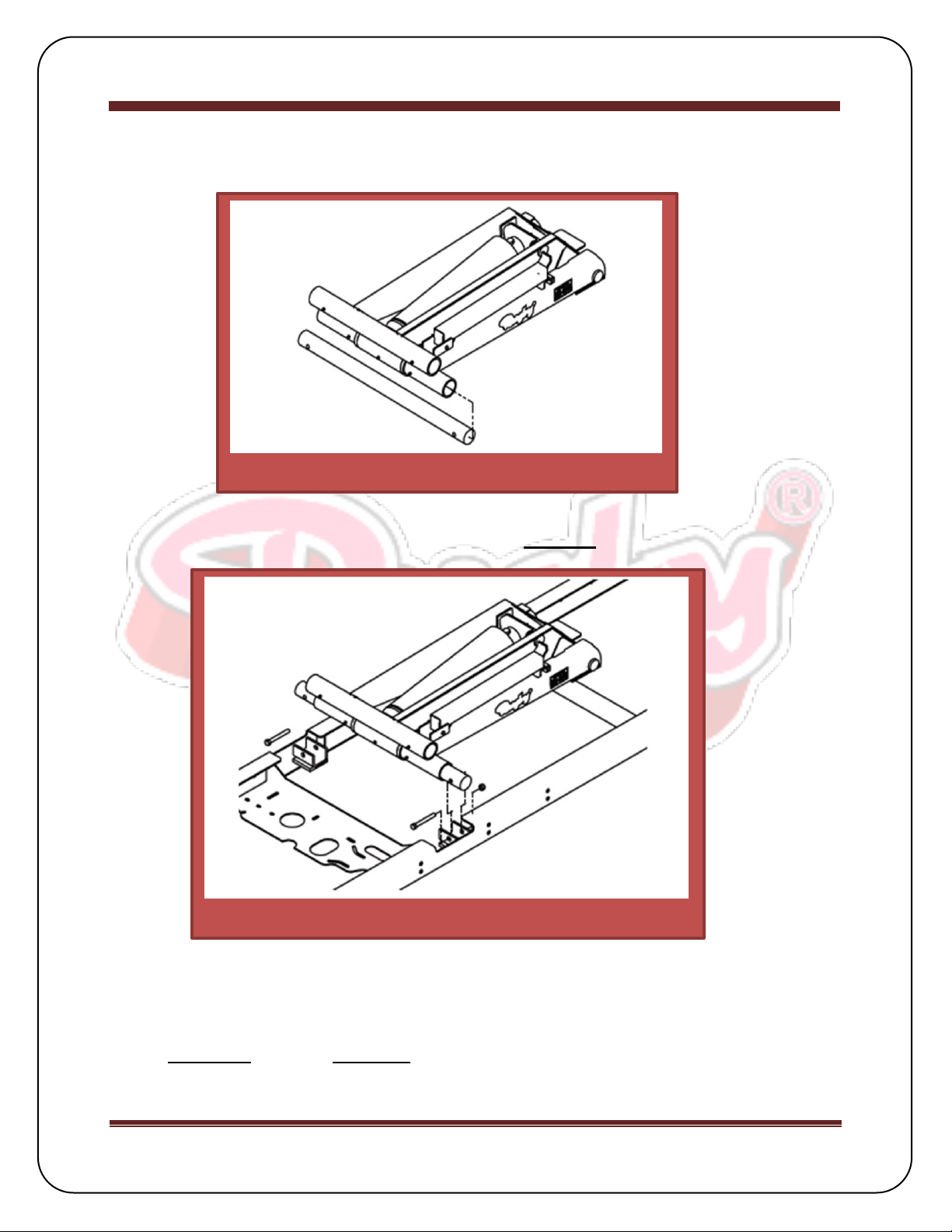

Hoist & Sub-frame Assembly....................................................................................7-8

Hoist & Subframe Installation..................................................................................8-13

45° Application Sub-frame Modification ....................................................................14

Decal Locations ......................................................................................................... 15

Operation................................................................................................16

Body Prop Operation.................................................................................................. 16

Maintenance...................................................................................... 16-17

Diagrams...............................................................................................................16-17