Installation, operating and maintenance manual SKIT/S-DEB 3rd print version page 6

Contents

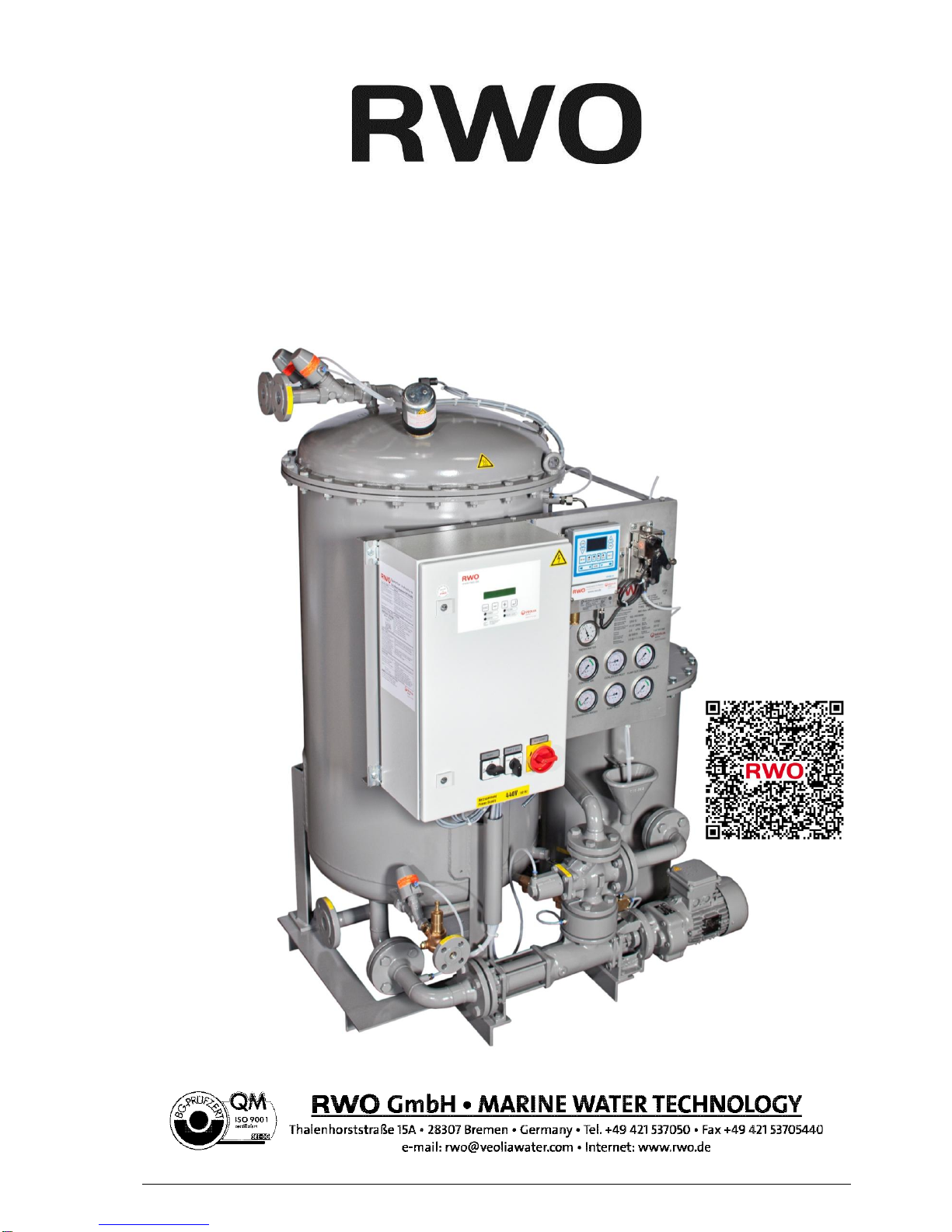

RWO GmbH ●Marine Water Technology ●Bremen ●Germany Issue 2014-04-10

14.3 Piston valve pos. 4 / Pos. 5 SKIT/S-DEB 10.0 m³/h 90

14.4 Sensor electrode pos. 9 91

14.5 3/2-way piston valve pos. 23 and pos.58 at SKIT/S-DEB 0.1 - 1.0 m³/h 91

14.6 3/2-way piston valve pos. 23 and pos. 58 at SKIT/S-DEB 1.5 – 10.0 m³/h 92

14.1 Coalescer pos. 34 SKIT/S-DEB 0.1 m³/h – 2.5 m³/h 92

14.2 Coalescer pos. 34 SKIT/S-DEB 5.0 m³/h – 10.0 m³/h 93

15 Annex ...............................................................................................................94

15.1 Checklist for commissioning 94

15.2 Record of the maintenance and repair works 97

List of tables

Tab. 1 Contact information...............................................................................................9

Tab. 2 Component overview ..........................................................................................16

Tab. 3 Component overview on pressure gauge board...................................................16

Tab. 4 Capacity, dimensions and weight, electric data....................................................21

Tab. 5 Electric data........................................................................................................21

Tab. 6 Component overview, pipe connections...............................................................22

Tab. 7 Pipe connections.................................................................................................23

Tab. 8 Type test certificates ...........................................................................................29

Tab. 9 Supply unit consumption list................................................................................36

Tab. 10 Valve terminal...................................................................................................38

Tab. 11 Component overview of control box...................................................................42

Tab. 12 Component overview, installation scheme .........................................................44

Tab. 13 Process overview..............................................................................................48

Tab. 14 Meaning of the message lights..........................................................................53

Tab. 15 Factory settings.................................................................................................60

Tab. 16 Table of faults...................................................................................................73

Tab. 17 Spare parts for SKIT/S-DEB 0.1 m³/h ................................................................75

Tab. 18 Spare parts for SKIT/S-DEB 0.25 m³/h...............................................................77

Tab. 19 Spare parts for SKIT/S-DEB 0.5 m³/h ................................................................78

Tab. 20 Spare parts for SKIT/S-DEB 1.0 m³/h ................................................................80

Tab. 21 Spare parts for SKIT/S-DEB 1.5 m³/h ................................................................81

Tab. 22 Spare parts for SKIT/S-DEB 2.5 m³/h ................................................................83

Tab. 23 Spare parts for SKIT/S-DEB 5.0 m³/h ................................................................84

Tab. 24 Spare parts for SKIT/S-DEB 10.0 m³/h...............................................................86

Tab. 25 Optional spare parts SKIT/S-DEB 0.1 m³/h to 10.0m³/h......................................86

Tab. 26 Tools ................................................................................................................87

Tab. 27 Component overview of control box...................................................................88

Tab. 28 Checklist...........................................................................................................96

List of figures

Fig. 1 Component overview............................................................................................15

Fig. 2 OMD and measuring cell......................................................................................16

Fig. 3 Automatic stop device..........................................................................................20

Fig. 4 Pipe connections..................................................................................................22

Fig. 5 Potentiometer ......................................................................................................25

Fig. 6 Lifting eyes X and Z.............................................................................................33

Fig. 7 Maintenance space of oil separator......................................................................34

Fig. 8 Maintenanceheight of oil separator......................................................................35

Fig. 9 Valve terminal......................................................................................................37