Page 9

MAINTENANCE

CORD REPLACEMENT

DISCONNECT THE SANDER FROM POWER SUPPLY

WHILE REPLACING PARTS OR MAKING ADJUSTMENTS.

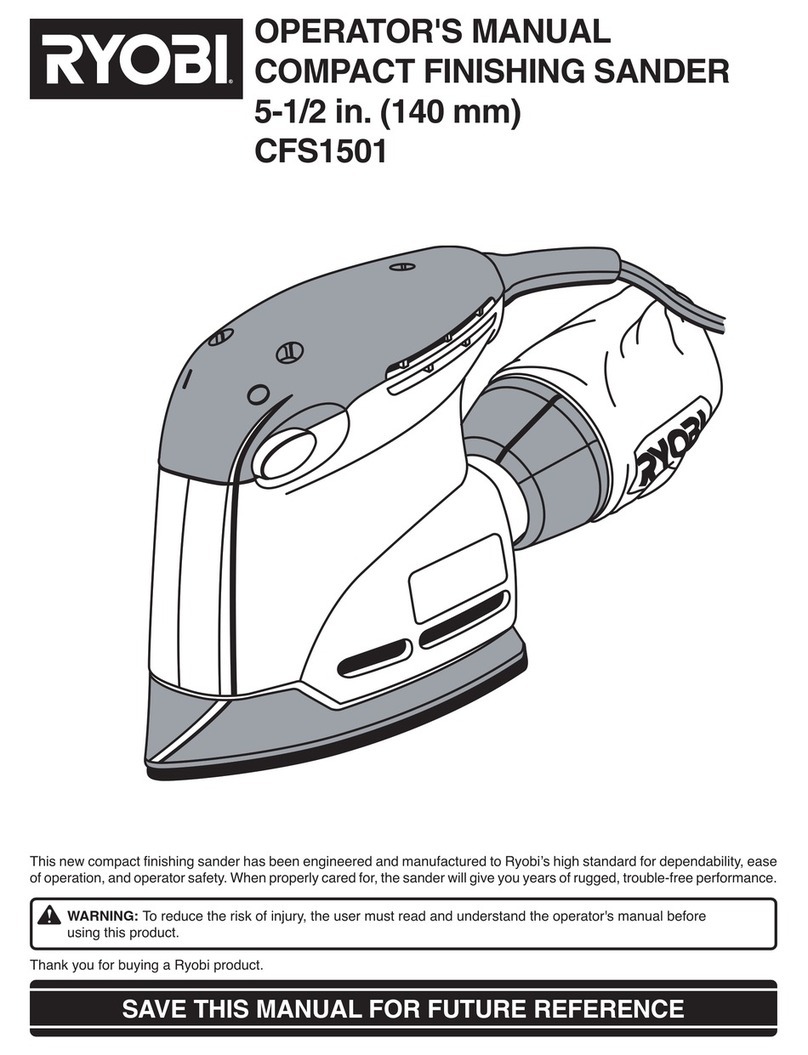

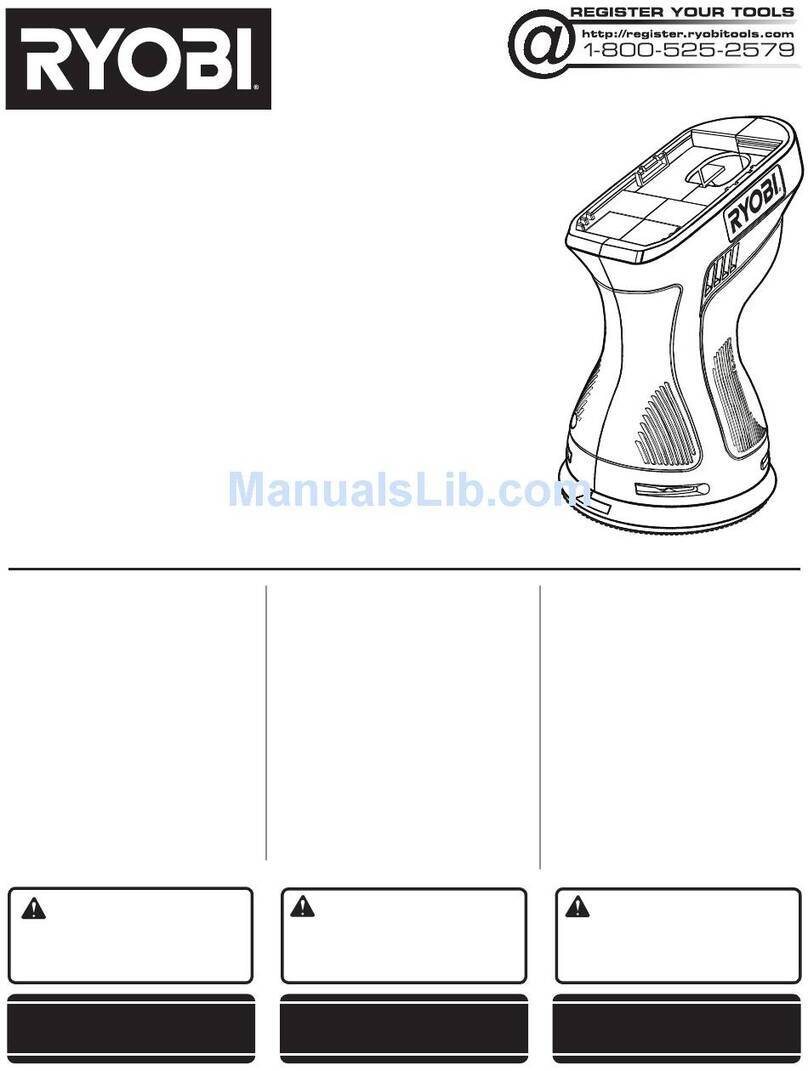

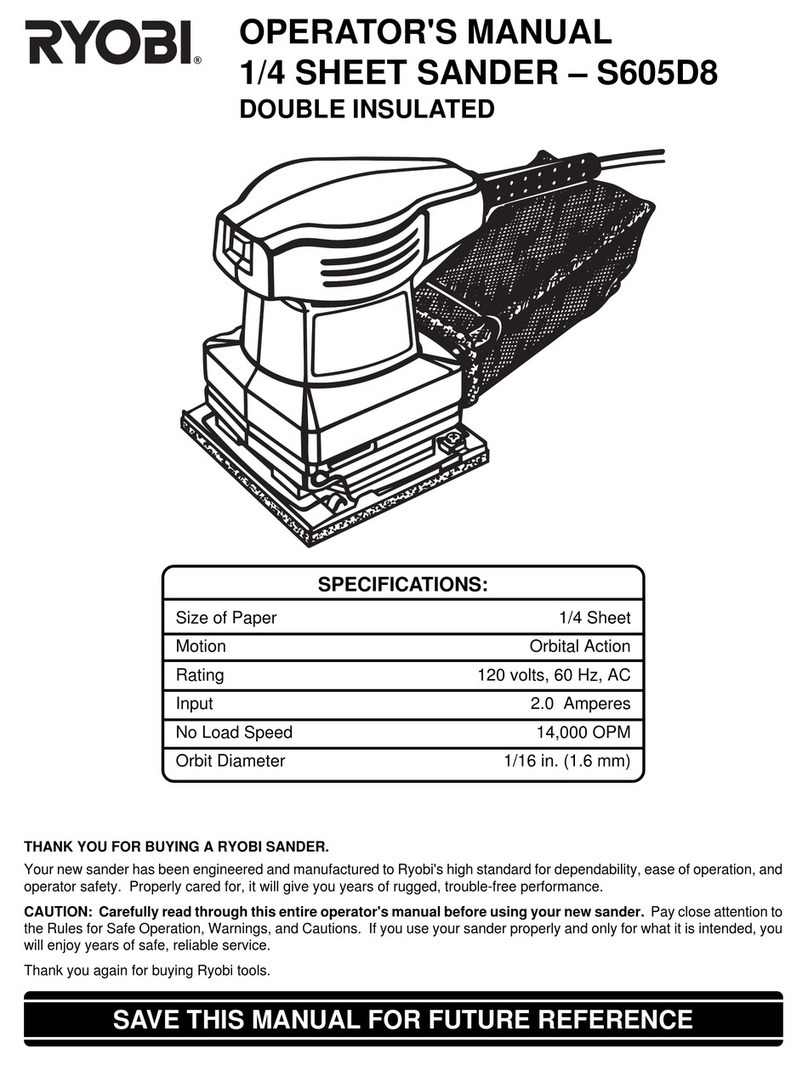

1. Remove handle cover and screws. NOTE THE

LOCATIONS OF ALL WIRING IN THE HANDLE AND

HOW EACH CONNECTION IS MADE TO THE CORD.

Connections and wiring position must be identical when

installing the new cord.

See

Figure 12.

2. Remove the cord clamp screws and cord clamp.

3. Lift the switch away from the handle. Release power cord

leads from the switch by loosening the two screws in the

switch body.

4. Remove the bend relief from the old cord and place it on

the new one.

5. Make new power cord lead connections to switch by

positioningleadsinplaceandtighteningthetwoscrewson

the switch body. Pull on leads to check lead connections

with lead receptacles.

6. Position the switch in place, and arrange all wiring in the

handlesothatitwillnotbepinchedorcontactscrewswhen

thehandlecoverandscrewsarereplaced.

SeeFigure12.

7. Arrangesuppressor,connectors,andsuppressorleadsin

the handle so that they will not be pinched or contact

screws when the handle cover and screws are replaced.

See Figure 12.

8. Replace cord clamp, cord clamp screws, handle cover,

and handle cover screws.

9. Tighten all screws securely.

Fig. 12

SWITCH REPLACEMENT

DISCONNECT THESANDERFROMPOWERSUPPLY WHILE

REPLACING PARTS OR MAKING ADJUSTMENTS.

1. Remove the handle cover and screws. NOTE THE

LOCATIONS OF ALL WIRING IN THE HANDLE AND

HOWEACHCONNECTIONISMADETOTHESWITCH.

Connections and wiring position must be identical when

installing the new switch.

See Figure 12.

2. Lifttheswitchawayfromthehandle.Release powercord

leads from the switch by loosening the two screws in the

switch body.

3. Release motor leads from switch by inserting a small

diameterpinornailintoremainingswitchleadreceptacles.

See Figure 12.

4. Make lead connections to the new switch by positioning

power cord leads in place and tightening the two screws

on switch body. Push motor leads as far as possible into

the switch lead receptacles. Pull on leads to check lead

connections with lead receptacles.

5. Positiontheswitchin place, and arrange the wiringinthe

handle so that it will not be pinched or contact screws

when the handle cover and screws are replaced.

See

Figure 12.

6. Arrange suppressor, connectors, and suppressor leads

in the handle so that they will not be pinched or contact

screws when the handle cover and screws are replaced.

See Figure 12.

7. Replace handle cover and screws.

8. Tighten all screws securely.

GENERAL

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to various types of commercial

solventsandmaybedamagedbytheiruse.Usecleancloths

to remove dirt, carbon dust, etc.

Whenelectrictoolsareusedonfiberglassboats,sportscars,

wallboard, spackling compounds, or plaster, it has been

foundthattheyaresubjecttoacceleratedwearandpossible

premature failure, as the fiberglass chips and grindings are

highly abrasive to bearings, brushes, commutator, etc.

Consequently it is not recommended that this tool be used

for extended work on any fiberglass material, wallboard,

spackling compounds, or plaster. During any use on these

materials, it is extremely important that the tool is cleaned

frequently by blowing with an air jet.

WARNING: ALWAYS WEAR SAFETY GOGGLES

OR SAFETY GLASSES WITH SIDE SHIELDS

DURING POWER TOOL OPERATION OR WHEN

BLOWING DUST. IF OPERATION IS DUSTY ALSO

WEAR A DUST MASK.

WARNING: DO NOT AT ANY TIME LET BRAKE

FLUIDS, GASOLINE, PETROLEUM-BASED

PRODUCTS, PENETRATING OILS, ETC., COME

IN CONTACT WITH PLASTIC PARTS. THEY

CONTAIN CHEMICALS THAT CAN DAMAGE,

WEAKEN, OR DESTROY PLASTIC.

BEND RELIEF

SCREWS

SCREWS

HANDLE COVER

SCREWS

SCREW

SWITCH

SUPPRESSOR

CORD CLAMP

WHITE

BLACK

CONNECTOR

CLEAR (GROUND)

SUPPRESSOR

SWITCH

SCREW

BROWN

LIGHT BLUE

YELLOW

POWER CORD

SMALL DIAMETER

NAIL OR PIN