these

touch

a

, as t

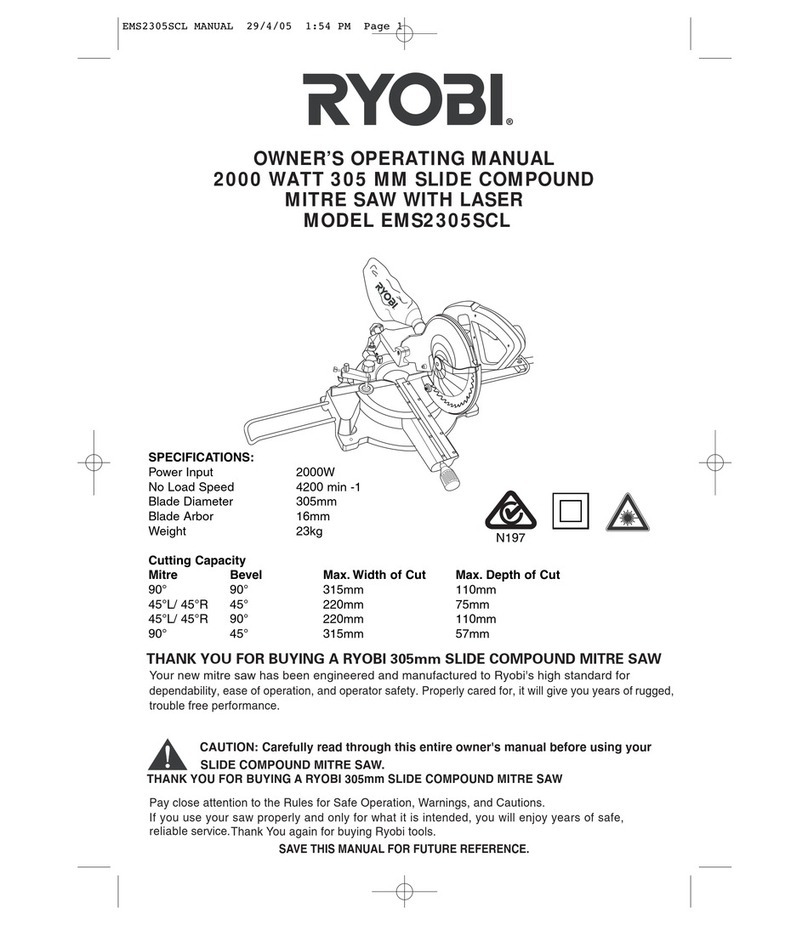

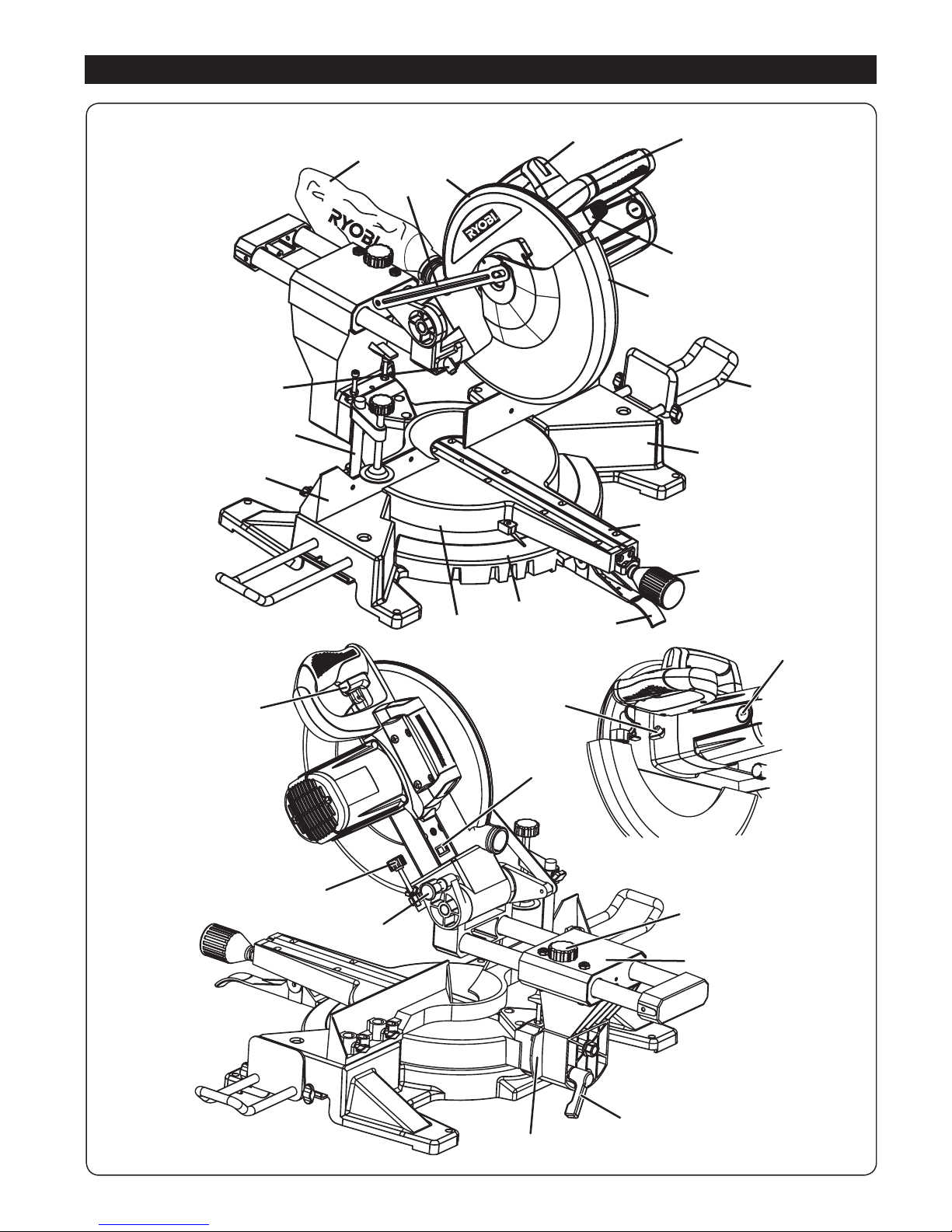

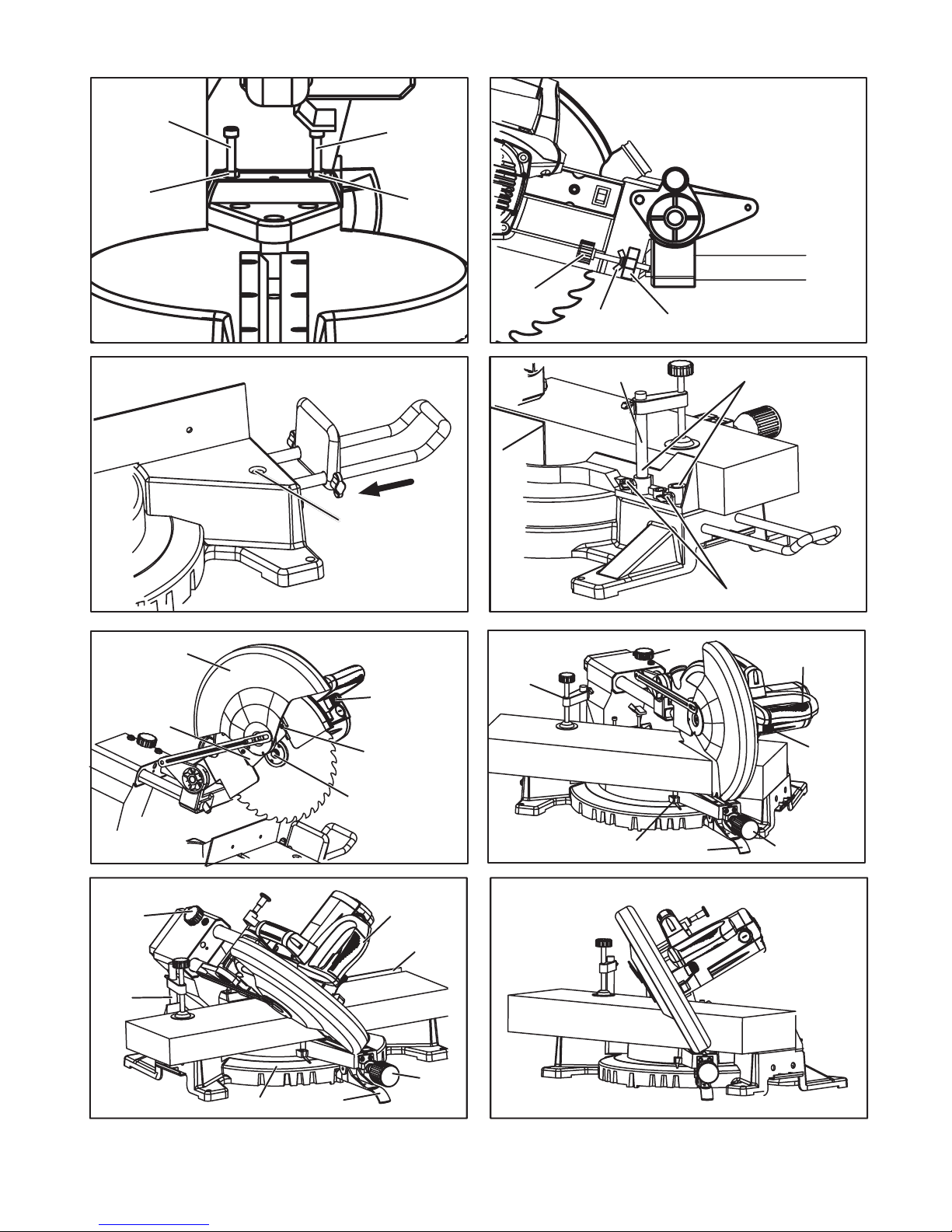

Due to continued product

refinement policy, product features

and specifications can and will

change without notice. Check

current features and specifications

with your retailer.

the,