1

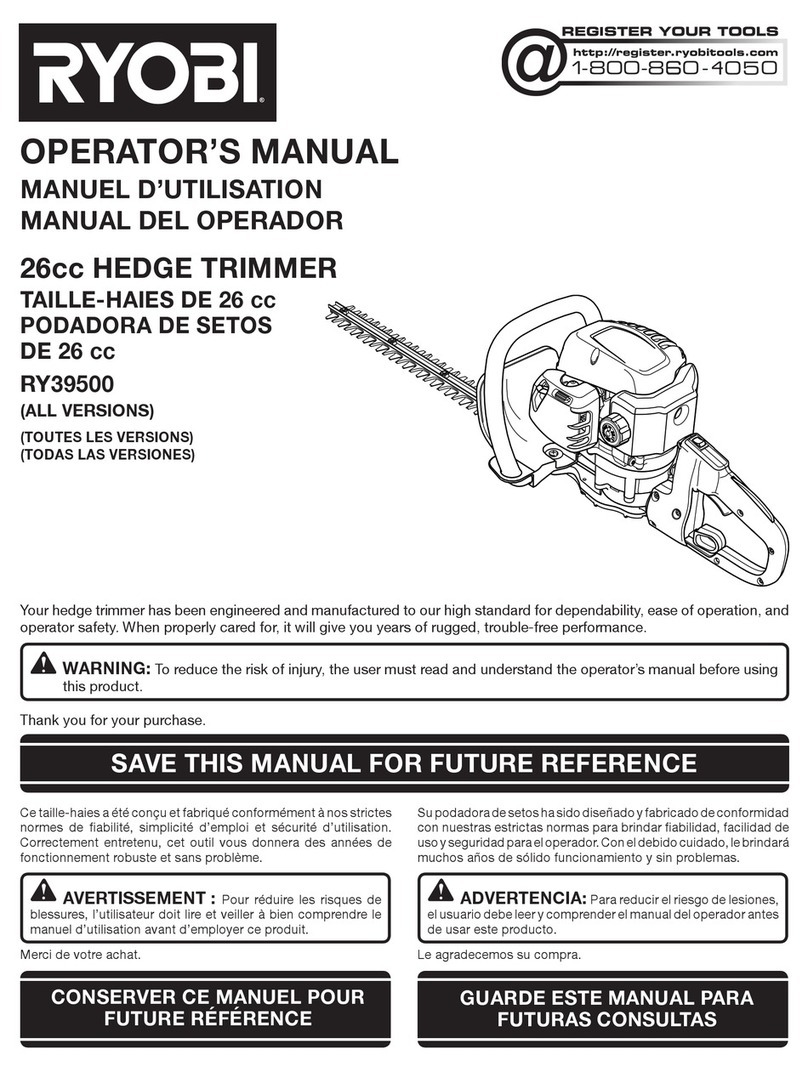

Your product has been engineered and manufactured to

Ryobi’s high standard for dependability, ease of operation,

and operator safety. Properly cared for, it will give you

years of rugged, trouble-free performance.

WARNING

To avoid serious personal injury, do not attempt to use

this product until you read thoroughly and understand

completely the operator’s manual. Failure to comply

may result in accidents involving electric shock, re,

and/or serious personal injury. Save this operator’s

manual and review frequently for continuing safe

operation and instructing others who may use this

product.

WARNING

The product is not designed for use with any other

Expand-It or similar type attachment. Only use the Pro

Cut attachment supplied with this engine. Using other

attachments will void your warranty.

READ ALL INSTRUCTIONS

GENERAL SAFETY RULES

■Do not allow children or untrained individuals to use

this product.

■Never start or run the engine inside a closed or poorly

ventilated area; breathing exhaust fumes can kill.

■Clear the work area before each use. Remove all

objects, such as rocks, broken glass, nails, wire that

can lead to accidents.

■Always wear eye protection with side shields marked to

comply with standards, along with hearing protection.

Failure to do so could result in objects being thrown

into your eyes and other possible serious injuries.

■Wear head and eye protection to prevent injury from

falling debris.

■Wear heavy, long trousers, boots and gloves. Do not

wear loose fitting clothing, shorts, jewelry of any kind,

or go barefoot.

■Secure long hair so it is above shoulder level to

prevent entanglement in any moving parts.

■Keep all bystanders, children, and pets at least 15 m

away.

■Do not operate this unit when you are tired, ill, or

under the influence of alcohol, drugs, or medication.

■Do not operate in poor lighting.

■Keep firm footing and balance. Do not overreach.

Overreaching can result in loss of balance or exposure

to hot surfaces.

■Keep all parts of your body away from any moving

part.

■Do not touch area around the exhaust, silencer or

engine of the unit; these parts get hot during operation.

■Always stop the engine and remove the spark plug

wire before refuelling, cleaning, maintenance or

storage.

■Inspect the unit before each use for loose fasteners,

fuel leaks, etc.

■Replace any damaged parts before use.

■Check for and tighten any loose parts.

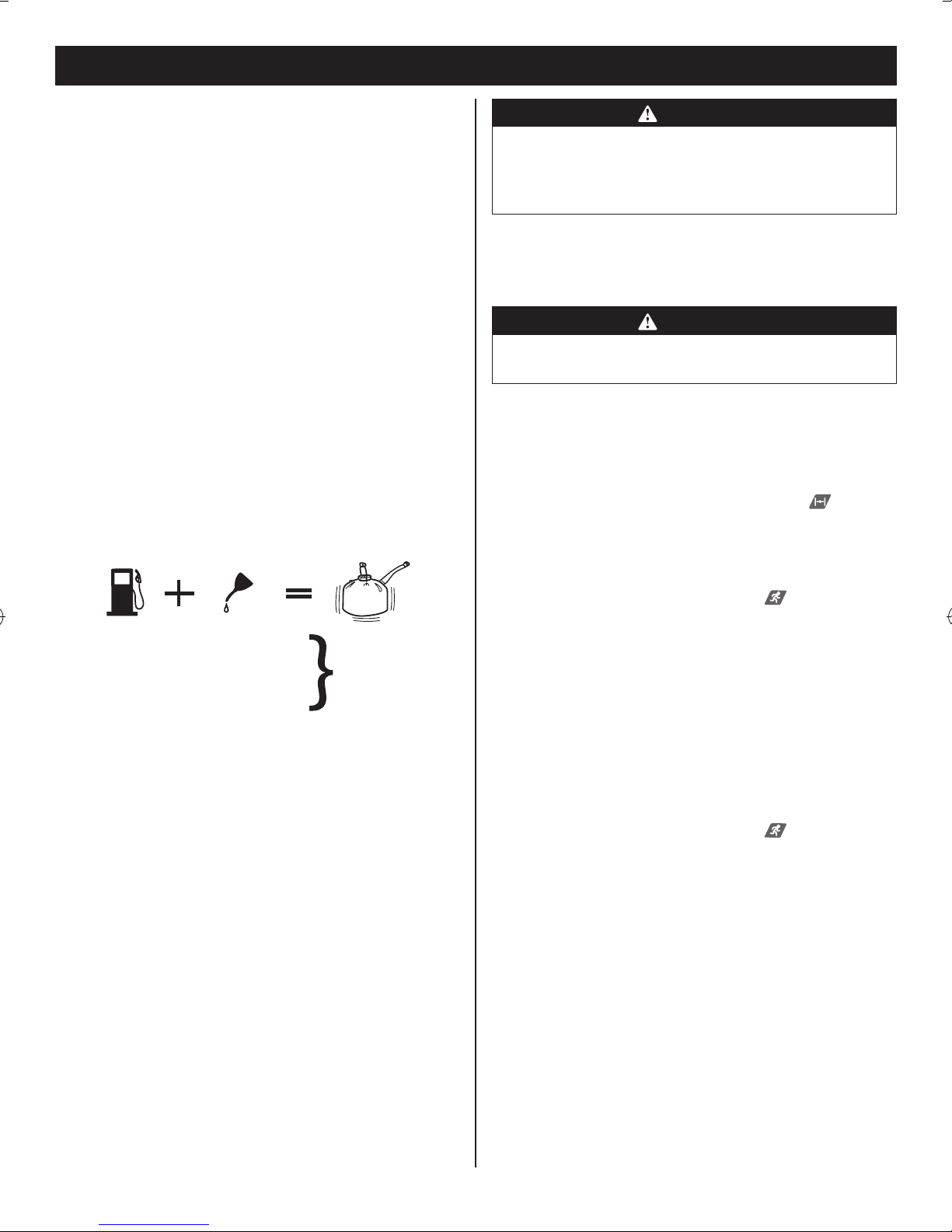

■Mix and store fuel in a container approved for fuel.

■Mix fuel outdoors where there are no sparks or flames.

Wipe up any fuel spillage. Move 9 m away from

refuelling site before starting engine.

■Stop the engine and allow to cool before refuelling or

storing the unit.

■Remove all debris from the work area before

operating.

■Keep bystanders (especially children) away from the

working area by 15 m.

■Allow the engine to cool; empty the fuel tank and

secure the unit from moving before transporting in a

vehicle.

■Wear your protective equipment and observe all

safety instructions. For units equipped with a clutch,

be sure the cutting attachment stops turning when the

engine idles. When the unit is turned off make sure

the cutting attachment has stopped before the unit is

set down.

■Heavy protective clothing may increase operator

fatigue, which could lead to heat stroke. During

weather that is hot and humid, heavy work should be

scheduled for early morning or late afternoon hours

when temperatures are cooler.

WARNING

Inspection after dropping or other impacts:

Thoroughly inspect the product and identify any

affections or damage with it. Any part that is damaged

should be properly repaired or replaced by an

authorised service centre.

SPECIAL SAFETY RULES

TRIMMER

■Replace string head if cracked, chipped, or damaged

in any way. Make sure the trimmer head is properly

installed and securely fastened. Failure to do so can

cause serious injury.

■Make sure all guards, deflectors and handles are