2

English (Original Instructions)

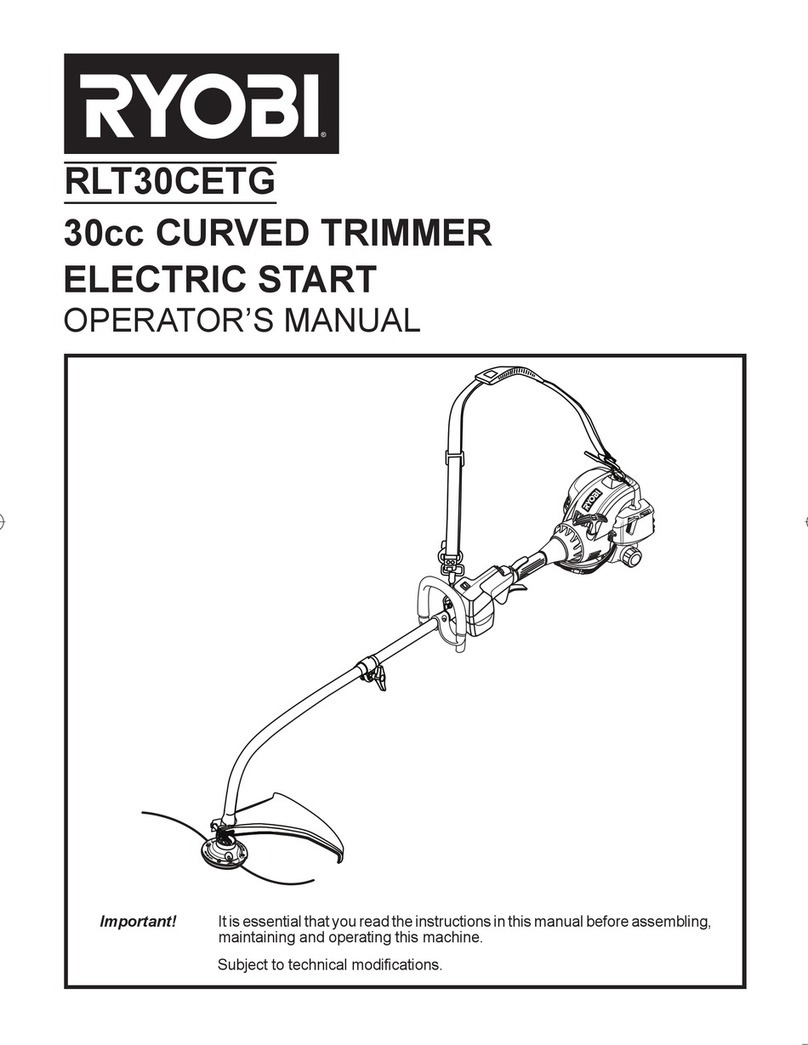

Your new trimmer has been engineered and manu-

factured to Ryobi’s high standard for dependability, ease

of operation, and operator safety. Properly cared for, it

will give you years of rugged, trouble-free performance.

INTENDED USE

This product is only intended for use outdoors in a well

ventilated area.

The product is intended for cutting long grass, pulpy

weed, brush and similar vegetation at or about ground

level. The product should not be used to cut or trim

hedges, bushes or other vegetation where the cutting

plane is not parallel to the ground surface.

WARNING

To reduce the risk of injury, the user must read

and understand the operator’s manual.

WARNING

Do not attempt to operate this trimmer until you

have read thoroughly and understood completely

all instructions, safety rules etc contained in

this manual. Failure to comply may result in

accidents involving fire, electric shock or serious

personal injury. Save operator’s manual and

review frequently for continuing safe operation,

and instructing others who may use this tool.

READ ALL INSTRUCTIONS.

GENERAL SAFETY RULES

nFor safe operation, read and understand all

instructions before using the trimmer. Follow all safety

instructions. Failure to follow all safety instructions

listed below, can result in serious personal injury.

nDo not allow children or untrained individuals to use

this unit.

nNever start or run the engine in a closed or poorly

ventilated area; breathing exhaust fumes can kill.

nClear the work area before each use. Remove all

objects such as rocks, broken glass, nails, wire,

or string which can be thrown or become entangled in

the bump head.

nWear full eye and hearing protection while operating

this unit.

nWear heavy long pants, boots, and gloves. Do not

wear loose fitting clothing, short pants, jewellery of

any kind, or use with bare feet.

nSecure long hair so it is above shoulder level to

prevent entanglement in any moving parts.

nKeep all bystanders, children, and pets at least 15 m

away.

nDo not operate this unit when you are tired, ill, or

under the influence of alcohol, drugs, or medication.

nDo not operate in poor lighting.

nKeep firm footing and balance. Do not overreach.

Overreaching can result in loss of balance or

exposure to hot surfaces.

nKeep all parts of your body away from any moving part.

nDo not touch area around the muffler or cylinder of

the trimmer, these parts get hot from operation.

nAlways stop the engine and remove the spark plug

wire before making any adjustments or repairs except

for carburetor adjustments.

nInspect the unit before each use for loose fasteners,

fuel leaks, etc. Replace any damaged parts before use.

nKeep the tool well maintained, fasteners tightened

and worn parts replaced.

nMix and store fuel in a container approved for fuel.

nMix fuel outdoors where there are no sparks or flames.

Wipe up any fuel spillage. Move 9 m away from

refueling site before starting engine.

nStop the engine and allow to cool before refueling or

storing the unit.

nAllow the engine to cool; empty the fuel tank and

secure the unit from moving before transporting in a

vehicle.

nDebris, when hit by the line, can travel significant

distances. Remove debris from the working area

before operating.

nOperating similar tools nearby increases risk of injury.

nUse of hearing protection reduces the ability to hear

warnings (shouts or alarms). The operator must pay

extra attention to what is going on in the working

area.

nIf working in an area where there is a risk of falling

objects, head protection must be worn.

SPECIFIC SAFETY RULES FOR TRIMMER USE

nReplace bump head if cracked, chipped, or damaged

in anyway. Be sure the bump head is properly

installed and securely fastened. Failure to do so can

cause serious injury.

nMake sure all guards, straps, deflectors and handles

Guaranteed sound power level is 113 dB.