S.E.A. Group SE400 User manual

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 1

Fan-supplied Positive-pressure Breath-responsive Respirator

User Instructions

600006 N

July2019

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 2

TABLE OF CONTENTS

ABOUT THESE USER INSTRUCTIONS.................................................................................. 3

DESCRIPTION OF THE SE400................................................................................................ 4

Main components.................................................................................................................. 5

Features ................................................................................................................................ 5

CAUTIONS AND LIMITATIONS............................................................................................... 6

UNPACKING............................................................................................................................. 7

FACEPIECE FITTING............................................................................................................... 8

QNFT Procedure................................................................................................................... 8

PREPARATION FOR USE ..................................................................................................... 10

Assembling the SE400........................................................................................................ 10

Donning the SE400............................................................................................................. 10

WORKING IN A CONTAMINATED AREA............................................................................. 14

Decontamination ................................................................................................................. 14

STORAGE AND TRANSPORT............................................................................................... 15

COMPONENTS OF THE SE400............................................................................................. 16

Fan unit................................................................................................................................ 16

Breathing hose .................................................................................................................... 16

SE-shield breathing hose.................................................................................................... 16

Facepiece............................................................................................................................ 16

Filtration media.................................................................................................................... 17

Batteries .............................................................................................................................. 19

Battery charger (BC3) ......................................................................................................... 22

Battery charger (BC1) ......................................................................................................... 22

Dual battery adapter (DB1) ................................................................................................. 23

SE-talk speaker unit............................................................................................................ 23

Back pack............................................................................................................................ 24

Waist belt............................................................................................................................. 24

SE-SHIELD PROTECTIVE ENSEMBLES.............................................................................. 25

Configurations ..................................................................................................................... 25

The SE-Shield range........................................................................................................... 25

OPERATION ........................................................................................................................... 27

Visible and audible warnings............................................................................................... 27

Warnings label on fan unit................................................................................................... 27

Warnings during start-up..................................................................................................... 28

Warnings during operation.................................................................................................. 29

Stand-by mode.................................................................................................................... 29

Demist mode ....................................................................................................................... 30

Menu mode ......................................................................................................................... 30

Self-Test.............................................................................................................................. 30

DISASSEMBLY AND REASSEMBLY.................................................................................... 32

CLEANING AND MAINTENANCE ......................................................................................... 35

Reconditioning after each use............................................................................................. 35

Cleaning the demand valve................................................................................................. 35

Replacing the visor (full facepiece) ..................................................................................... 38

SPARE PARTS AND ACCESSORIES................................................................................... 39

TROUBLESHOOTING............................................................................................................ 40

OPERATION IN EXTREME CONDITIONS............................................................................. 41

SE-DATA................................................................................................................................. 41

IMPORTANT WARRANTY INFORMATION........................................................................... 41

IN CASE OF HEAVY IMPACT................................................................................................ 41

APPROVAL BODIES.............................................................................................................. 42

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 3

Warning (USA)

Before occupational use of this respirator a written respiratory protection program must be

implemented meeting all the local government requirements. In the United States employers

must comply with OSHA 29 CFR 1910.134 which includes medical evaluation, training, and fit

testing.

ABOUT THESE USER INSTRUCTIONS

These user instructions refer to the following user instructions for components and accessories

of the SE400:

Supplementary manual –SE400 advanced functions (600007)

SE-shield Tychem F©suits (100184-04)

SE-shield Tyvek©and Tychem QC©suits (100325-03)

SE-shield encapsulated suits (100292-02)

Tychem F©Hood (100259-04)

Breathing hose cover HC-TF (100257-03)

Foam insert SEA-FI (100287-03)

GBCO (600010)

Fit test adapter FTA-400 (100288-03)

Back pack BP2 (100267-03)

Exhalation valve shield EVS (201540-03)

Dual battery adapter DB1 (100273-03)

The above user instructions are supplied with the components. They are also available at The

S.E.A. Group website, www.theseagroup.com

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 4

DESCRIPTION OF THE SE400

The SE400 is a powered air-purifying respirator (PAPR) designed to give protection from

breathing hazards. It is a high-performance PAPR known as an FPBR (Fan-supplied Positive-

pressure Breath-responsive Respirator).

The SE400 has a built-in microprocessor that monitors the user’s breathing pattern and

adjusts the airflow to ensure continuous positive pressure in the facepiece even during high

exertion.

Because the SE400 delivers breathing air only when needed, battery power and filtration

media capacity are conserved.

Positive pressure

Positive pressure increases breathing protection.

An airtight “face seal” – between the facepiece and the user’s face – is critical for good respiratory

protection. In practice it is very difficult to maintain a perfectly airtight face seal under all conditions.

Even momentary loss of sealing can greatly reduce the level of protection.

By maintaining a slightly elevated air pressure inside the facepiece at all times, any leakage will flow

outward, thus preventing inward leakage of contaminated air to the breathing zone.

A conventional PAPR delivers an essentially constant flow of breathing air to the facepiece. During high

exertion the user may take very deep breaths that momentarily exceed the delivery rate of the PAPR. At

these times the facepiece pressure becomes negative and inward leakage of contaminants can occur.

Because the SE400 “FPBR” is breath-responsive, continuous positive pressure can be maintained at

peak inhalation airflows up to and exceeding 350 litres per minute.

Positive pressure reduces breathing resistance.

Because the air in the breathing zone is maintained at a very small positive pressure, the user feels little

or no breathing resistance. By reducing the breathing effort and discomfort, he or she has more energy

and awareness to do the job at hand.

The SE400 is currently available in the following models:

SE400AT-2 –Two-filter fan unit for industrial applications

SE400AT-2 Advanced –Two-filter industrial unit with advanced functionality

SE46 –Three-filter fan unit for emergency response applications –includes increased

peak flows, battery duration, gas filter capacity and chemical resistance; Advanced

functionality; Normally fitted with Exhalation Valve Shield (EVS) and single-use

Tychem F®hose cover (HC-TF)

Note: SE400AT-2 Advanced and SE46 users should consult the supplementary manual

“SE400 Advanced Functions” on the CD-ROM provided with those models.

Note (USA): SE400 and SE46 respirators are approved by NIOSH for use in industrial

environments. They are not CBRN-approved.

Note: The SE400AT-2 supersedes the SE400AT. SE-Talk speaker unit and PC data cable are

not interchangeable between these models.

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 5

Main components

A comprehensive list of components is given in section Components of the SE400.

1. Fan unit (SE400AT-2 shown)

2. Filtration media

3. Breathing hose

4. Facepiece

5. Demand valve

6. Battery

7. SE-Talk speaker unit

8. Back pack

9. Prefilters and prefilter holders

Features

1. ON/OFF button

2. Status lights panel

3. Communication socket

4. Threaded connectors for

filtration media

5. Threaded nuts for attachment

to SE-shield protective suits

6. Warning light

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 6

CAUTIONS AND LIMITATIONS

When using this respirator, observe the following cautions and limitations.

Oxygen levels

Not for use in atmospheres containing less than 19.5% oxygen.

This respirator delivers purified ambient air. It does not generate oxygen.

Breathing hazards

Not for use in atmospheres immediately dangerous to life and health (IDLH) or where

hazards have not been fully characterised.

Do not exceed maximum use concentrations established by regulatory standards.

If you sense any of the following danger signals:

osmell or taste of contaminants

oeye, nose or throat irritation

obreathing difficulty

ouncomfortably warm breathing air

odizziness, nausea or vomiting,

immediately leave the contaminated area. Do not remove the respirator until you

have reached clean air and after decontamination as required.

Explosive atmospheres

Contains electrical parts which may cause an ignition in flammable or explosive

atmospheres. Do not use in flammable or explosive atmospheres.

Exposure to flame

Do not use in contact with flame. Do not use for fire fighting.

Dermal (skin) hazards

Use in conjunction with personal protective ensembles that provide appropriate levels

of protection against dermal hazard. Failure to do so may result in personal injury

even when the respirator is properly fitted, used and maintained.

Follow these User Instructions

Failure to properly use and maintain this respirator could result in injury or death.

Follow these user instructions and established canister change-out schedules to ensure

canisters are replaced before breakthrough occurs.

Never substitute, modify, add or omit parts. Use only exact replacement parts in the

configuration as specified by the manufacturer.

Compliance with regulations

(USA) All approved respirators shall be selected, fitted, used and maintained in

accordance with MSHA, OSHA and other applicable regulations.

Use replacement parts in the configuration as specified by the applicable regulations

and guidance. Consult the respirator Approval Label (USA) for approved

configurations.

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 7

S - Special or Critical User's Instructions (USA)

Foam Inserts

If Facepiece Fit Testing fails due to particular facial contours, SEA recommends that the SEA

Full Face Mask Foam Insert (model number SEA-FI) be inserted into the facepiece. Please

refer to the User Instructions for the foam inserts or contact an SEA Group representative for

more information.

Note: NIOSH has classified the foam inserts as a required component. However, foam inserts

shall only be used in cases where a satisfactory facepiece fit cannot be achieved without them.

UNPACKING

The following parts are included with the SE400:

Fan unit

Breathing hose and hose latch retainer

Facepiece with demand valve and head harness

Waist belt

Prefilters and prefilter holders

SE400 user instructions

Cleaning tissues

Up to two (2) batteries (level of charge not assured)

Battery charger with power supply and AC power cable

Speaker unit

CD-ROM containing user instructions and management software (Advanced only)

Data cable for connection to PC (Advanced only)

NIOSH Approval Label (USA)

Single-use breathing hose cover (SE46 only)

Exhalation valves shield (SE46 only)

Check that all components are received as ordered, and undamaged.

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 8

FACEPIECE FITTING

Note: This section applies to full facepiece respirators only.

The SE400 is designed to maintain positive pressure inside the facepiece even under

conditions of high workload and stress. However, a quality face seal is essential for optimum

protection. This is particularly important in the event that the blower unit stops operating and

the SE400 must function as a negative pressure respirator.

A user must pass a Quantitative Fit Test (QNFT) and achieve a fit factor of at least 2000

before being assigned a full facepiece respirator. This is a negative pressure test; i.e.: with the

fan unit disconnected or not operating.

Quantitative Fit Test

A Quantitative Fit Test (QNFT) gives a numerical measure of facepiece fit.

The user wears a respirator in a test atmosphere while an instrument compares the

concentration of the challenge agent in the test atmosphere with that inside the facepiece.

The test atmosphere may be air contaminated with an aerosol, vapour or gas. With some

instruments ambient air can be used.

The QNFT protocol must be in accordance with appropriate government regulations.

Facepiece fit testing has a number of aims:

1. To assess the suitability of the respirator for each person for use in real situations.

Due to natural variations in human facial features, no one size or style of full

facepiece can be guaranteed to fit everyone. A QNFT, properly conducted, can be

used to determine if the respirator is suitable for each user.

2. If the respirator is found to be unsuitable, to determine if the same respirator fitted

with the Full Face Mask Insert (SEA-FI) is suitable.

The Full Face Mask Insert is an adhesive-backed foam strip, inserted behind the

face seal, intended to accommodate unusual facial features or small faces. Once

again, a QNFT must be performed to determine if this configuration is suitable

for each user.

3. To train each user in the correct donning technique that will ensure a good facial fit

during future use.

It is extremely important that the donning technique learned by each user during

the QNFT is employed in all future use, where fit testing will not normally be

available. In particular, the head harness tension used to pass the QNFT should be

appropriate for extended use in real situations; if excessive harness tension is

needed to pass, the respirator should be considered unsuitable, and should not be

used by that person.

QNFT Procedure

The recommended method for performing the QNFT is with the S.E.A. Fit Test Adapter

(FTA-400). Alternatively, a modified test facepiece may be used.

Both methods are described below.

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 9

To prepare for a QNFT using the Fit Test Adapter FTA-400:

1. Detach the breathing hose from the SE400 facepiece

2. Attach the FTA-400 to the facepiece in place of the breathing hose and attach a

HE/P100 particulate filter, following the user instructions provided with the FTA-

400. The SE400 facepiece is now configured as a negative pressure respirator. The

SE400 fan unit is not required for this test

3. Check that the facepiece, demand valve and FTA-400 are complete and correctly

assembled

4. Don the respirator in accordance with section Donning the SE400 step 2, steps 4

through 8 and step 12

To prepare for a QNFT using a test facepiece:

1. Detach the breathing hose from the SE400 facepiece

2. Attach to the breathing hose a modified SE400 test facepiece containing a sampling

port connecting to the breathing zone of the facepiece. The test facepiece should be

leak tested by a suitable method prior to use.

3. Fully assemble the SE400, including filters. The SE400 can now be tested, with the

blower off, as a negative pressure respirator

4. Don the respirator in accordance with section Donning the SE400 steps 1 through 8

and steps 12 and 15

To perform a QNFT:

1. Prepare and don the respirator using one of the methods described above

2. An assistant should inspect the fit of the respirator. Check for significant gaps

between the rim of the facepiece and the user’s face. If significant gaps are visible,

consider fitting the Full Face Mask Insert (SEA-FI). Doff the facepiece, fit the Insert

in accordance with its user instructions, and don the facepiece as before.

3. Enter the test atmosphere (if required) and connect the test instrument’s sampling

tube to the sampling port on the FTA-400 or test facepiece

4. Perform an appropriate QNFT exercise sequence and determine the fit factor

i. If the fit factor is 2000 or greater, the respirator should be considered

suitable for the user. No further testing is required

ii. If the fit factor is less than 2000, an observer should check that the

respirator is correctly assembled, and properly fitted in accordance

with section Donning the SE400 step 12. The user should check head

harness tension and adjust if necessary. Go to step 5 below

iii. If during step ii above the observer detects fitting problems which

cannot be overcome by adjustment –in particular, visible gaps

between sealing rim and the user’s face –the Full Face Mask Insert

(SEA-FI) may provide a solution. Doff the facepiece, fit the Insert in

accordance with its user instructions, and don the facepiece as before.

Go to step 5 below

5. Repeat the QNFT and determine the fit factor

oIf the fit factor is 2000 or greater, the respirator in the configuration tested –

with or without Insert as appropriate –should be considered suitable for the

user. No further testing is required

oIf the fit factor is again less than 2000 the respirator should be considered

unsuitable and should not be used by that person

Note: Some “trial and error” is acceptable when carrying out facepiece fit testing. Sound

judgement by experienced personnel is essential when assessing the suitability or otherwise of

a respirator. Remember that the donning and adjustment method used during testing must be

appropriate for subsequent use in real situations.

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 10

PREPARATION FOR USE

Assembling the SE400

Before use, check that the SE400 is fully assembled. To assemble, consult the relevant section

of the user instructions, as noted below.

Breathing hose connection to fan unit –consult section Disassembly and reassembly

Breathing hose connection to facepiece –consult section Disassembly and reassembly

SE-talk speaker unit –consult section Disassembly and reassembly

Battery –consult section Batteries

Harness:

oStandard waist belt –consult section Waist belt

oBack pack –consult user instructions supplied with the back pack

Dual battery adapter (if required) –consult user instructions supplied with the adapter

Filtration media –consult section Filtration media

Donning the SE400

The user must be familiar with and practise the donning and doffing procedures prior to

respirator use.

Warning

Men should be clean-shaven, and should not have facial hair such as beards or large

sideburns. Facial hair can seriously compromise the face seal and result in reduced

protection.

Note: Before donning a respirator for the first time, perform a facepiece fit test per section

Facepiece Fitting (applies to full facepieces only).SEA recommends that each new (unused)

respirator be tested for facepiece fit even if the user is experienced with the respirator.

Note: Users who have been approved to use the SE400 only with Full Face Mask Insert (SEA-

FI) should check that the insert is correctly fitted and is in good condition prior to donning.

Note: Before first use and after maintenance, perform a respirator “Self-Test”. Refer section

Operation.

Note: Users should be well hydrated before donning and using the respirator.

Note: When donning the SE400 with an SE-shield protective suit, consult the SE-shield user

instructions.

Procedure:

1. Visually inspect the respirator for completeness, correct assembly and lack of

damage

2. Put the facepiece neck strap over your neck

3. Put on the fan unit (with back pack or waist belt) and adjust the straps

4. Fully loosen the head harness straps

5. Clear all hair away from your face. A thin elasticised head band may be used,

provided it is kept clear of the face seal

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 11

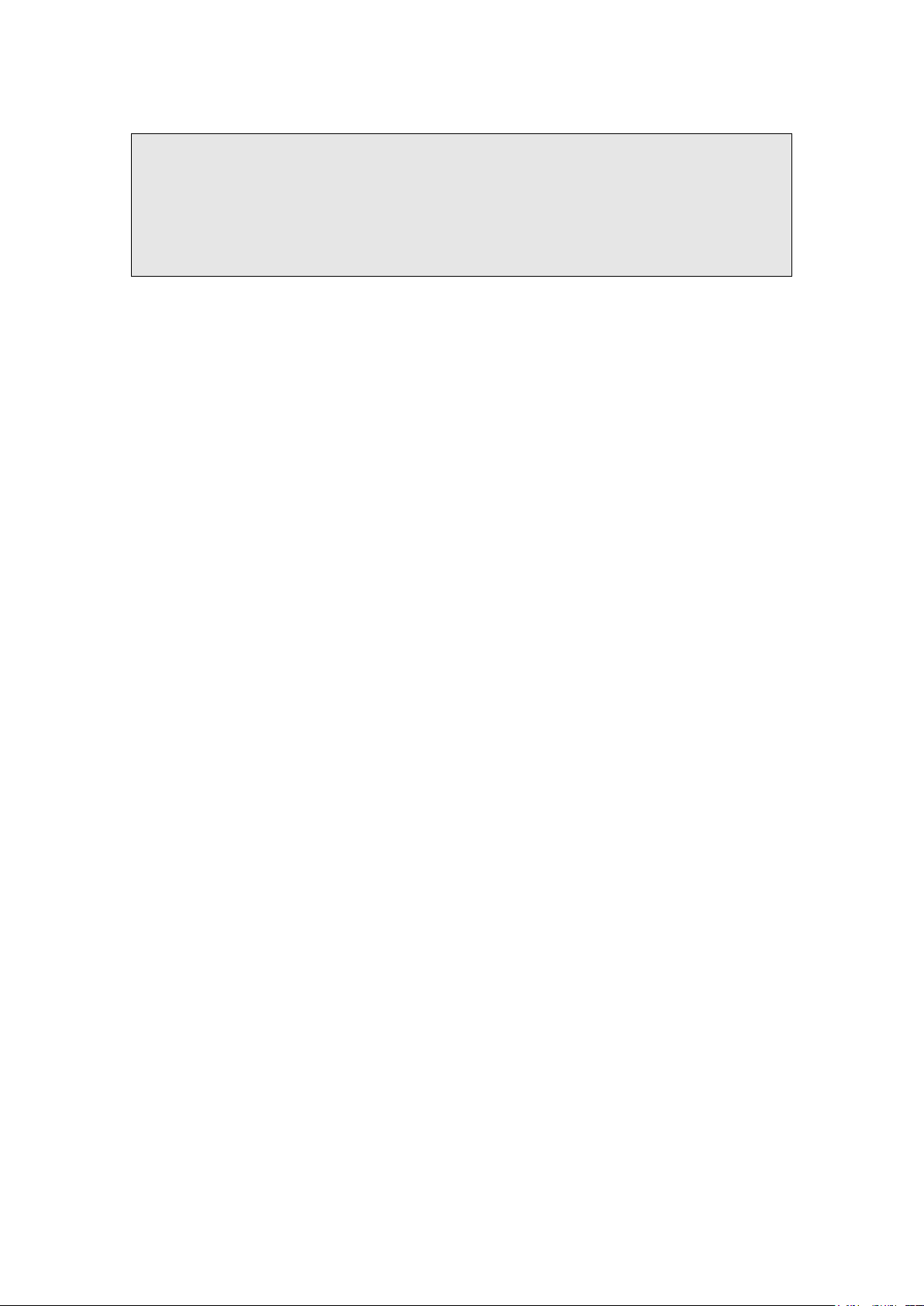

For full facepiece only:

6. Holding the facepiece in one hand and the

head harness in the other, place your chin in

the cup of the facepiece

7. Pull the head harness over and down the

back of your head and stroke it down. Clear

any hair away from the face seal

8. Tighten the head harness straps in pairs by

pulling the free ends backwards. Start with the

neck straps, followed by the temple straps

and finally the forehead strap

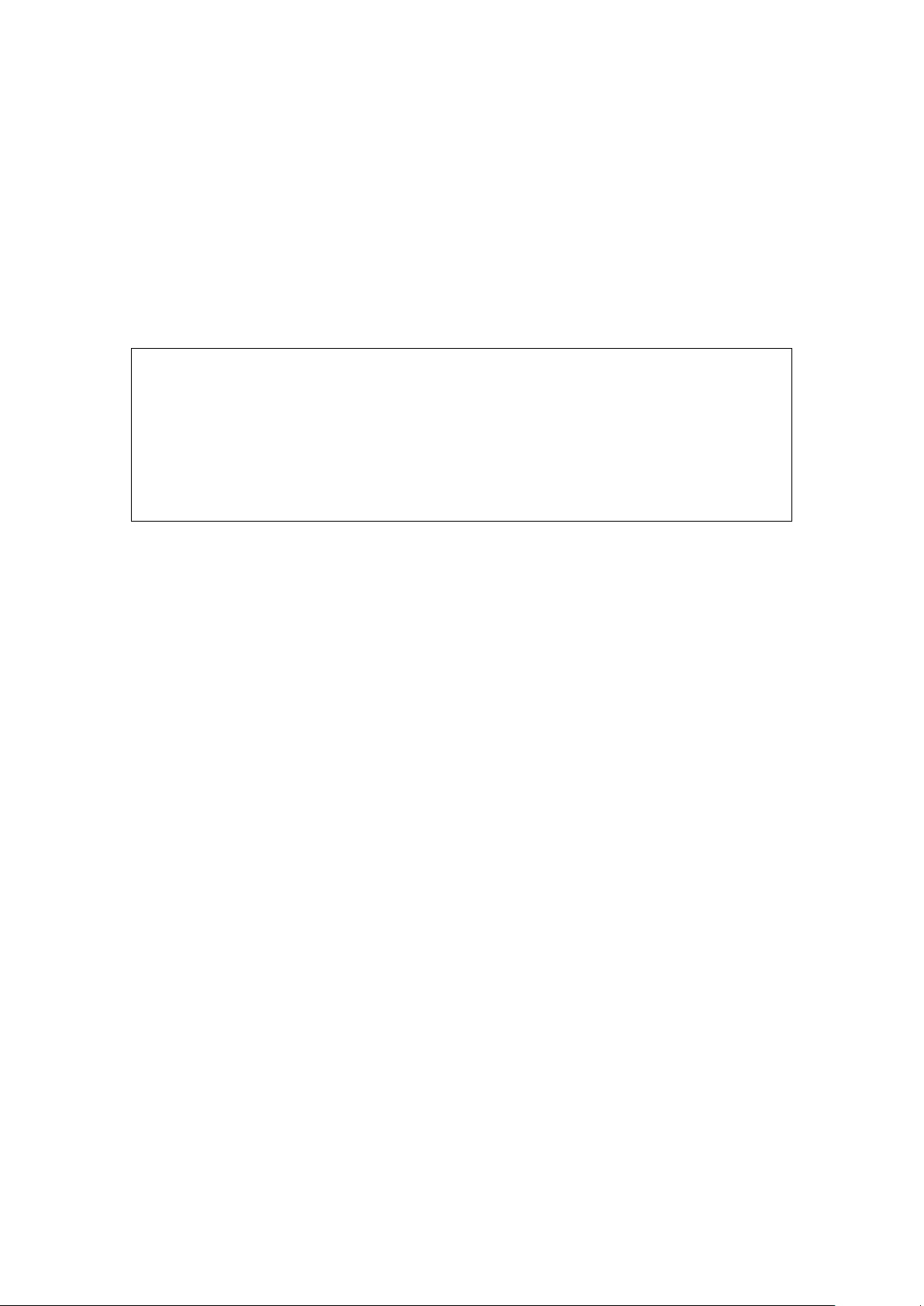

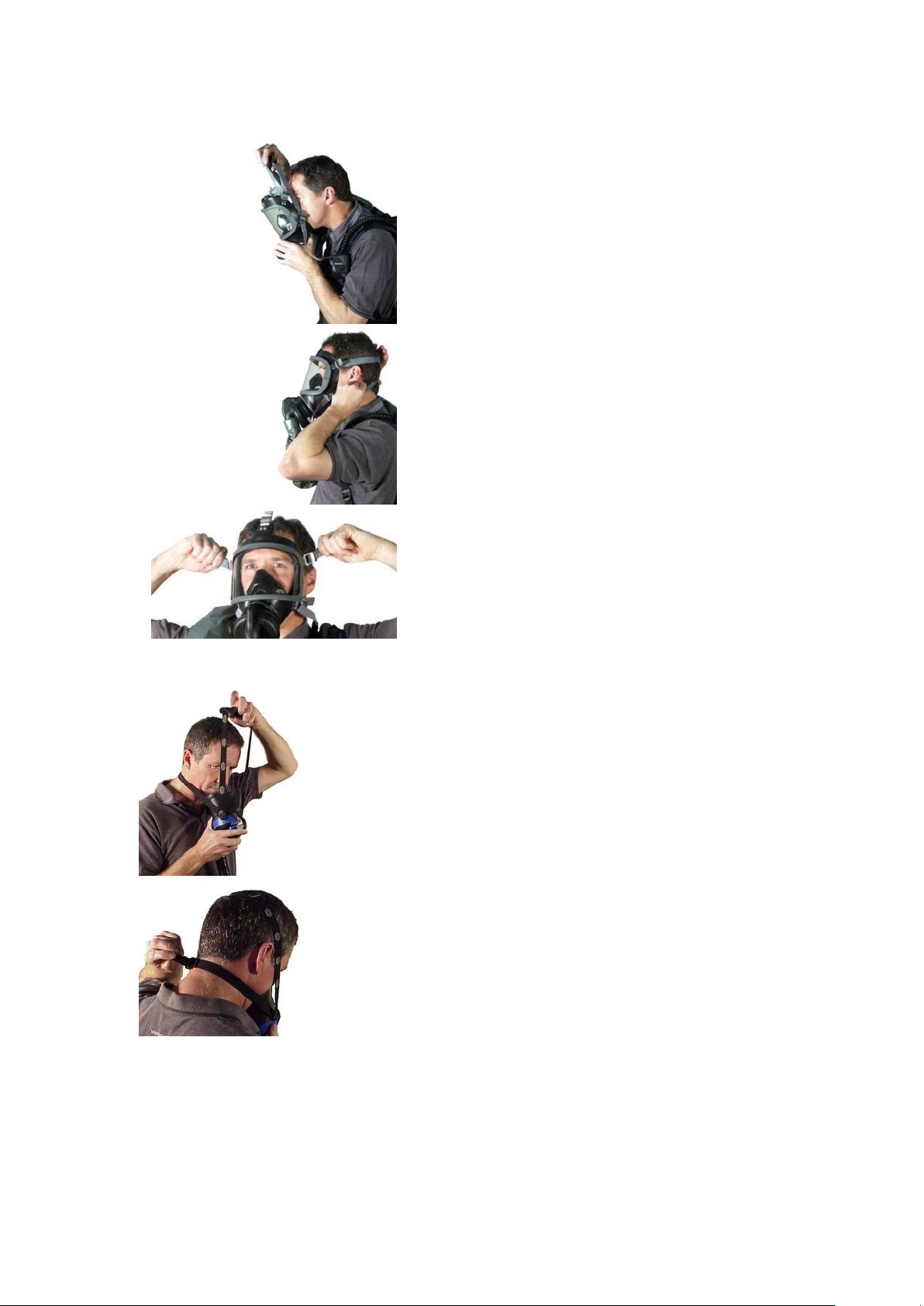

For half facepiece only:

9. Don the half mask so that the harness pad

rests on the crown of the head

10. Release the snap-catch at the back of the

head, adjust the harness tension, and lock the

snap-catch

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 12

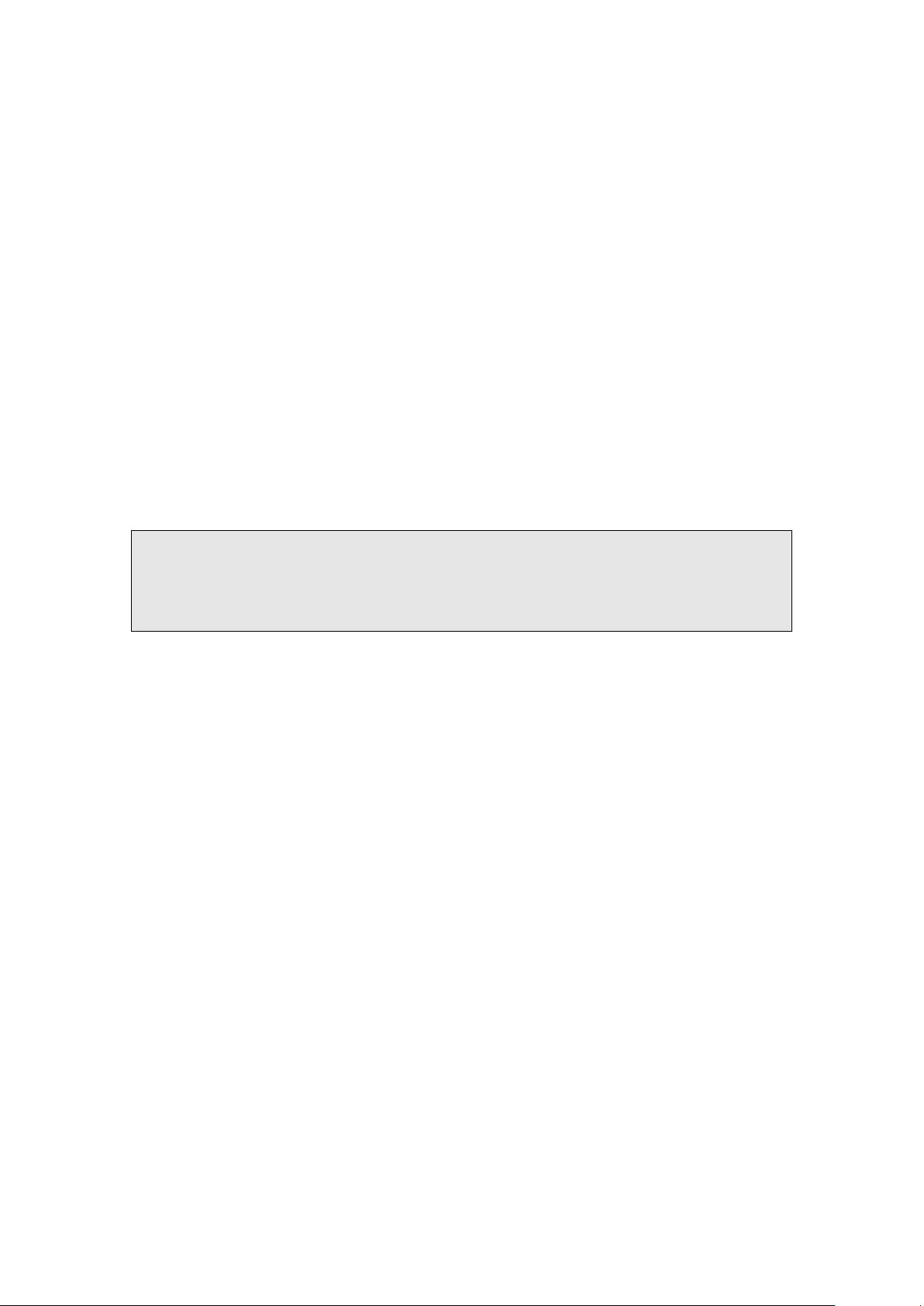

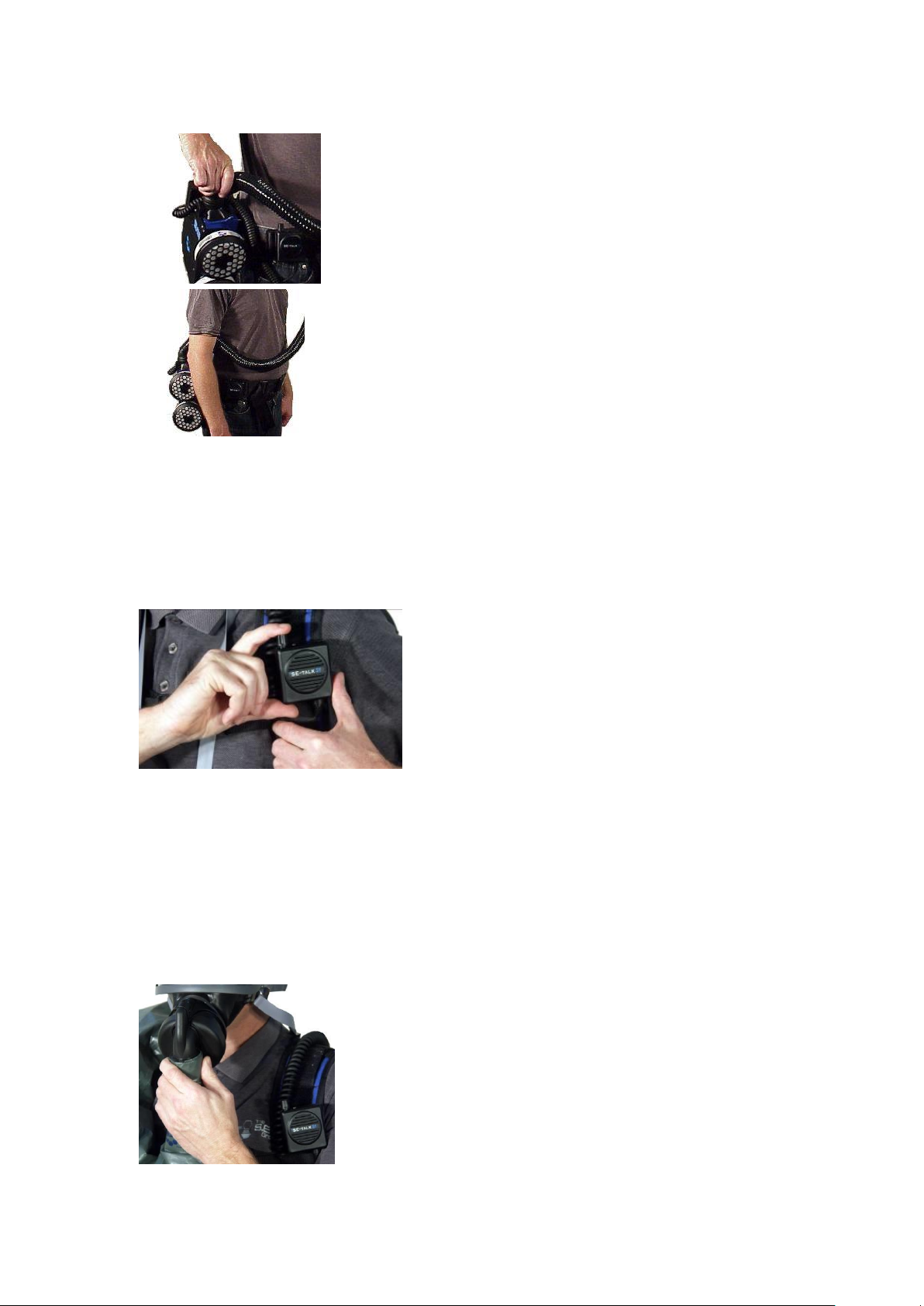

For standard waist belt only:

11. Position the fan unit on the either side of the

body as desired. Adjust the breathing hose

swivel to position the hose. Mount the SE-Talk

on the breast pocket, or on the belt (shown)

using the SE-Talk belt attachment HSE

CAUTION: The fan unit should always be worn

with the filtration media facing downwards or to

one side, but never facing upwards.

For all configurations:

12. Check that the face seal touches the skin all around, especially under the chin cup

and at the temples. Try moving the mask to verify that there is no slippage. The straps

should be tightened firmly enough to prevent movement on the face during use, but

should not be overly tight. Excessive tightness may lead to increasing discomfort

during use. Check once again that there is no hair under the face seal

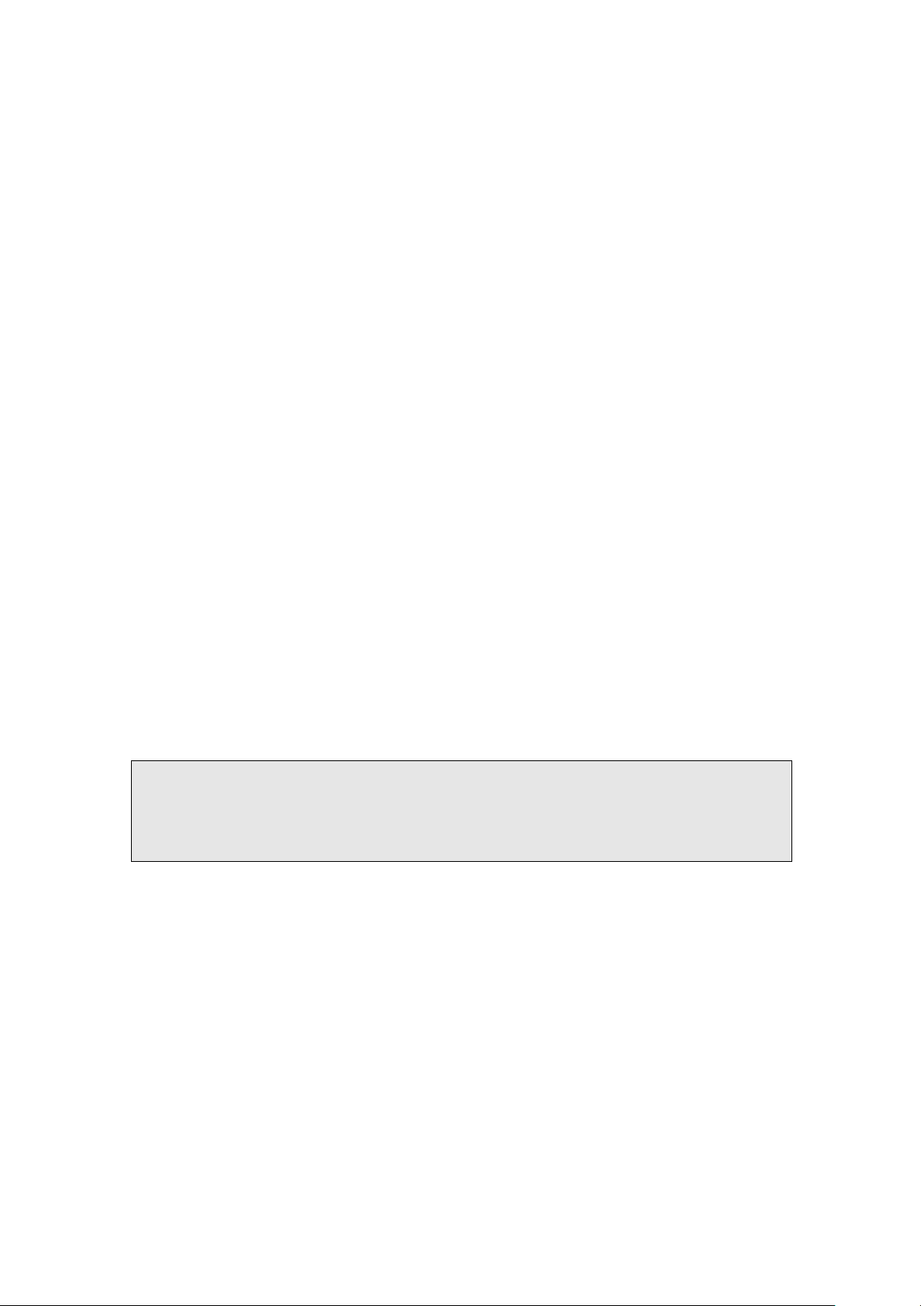

13. Turn on the fan unit by pressing and

releasing the button on the speaker unit.

Alternatively, press and release the ON/OFF

button on the fan unit

14. Perform a User Seal Check * by pressing and holding the SE-Talk button for more

than three seconds, causing the SE400 to run at full fan speed (“Demist mode”). You

should not feel any air leakage around the face seal. After 20 seconds the SE400

automatically returns to normal operating mode. If any leakage is evident, correct

immediately by re-stroking the head harness to the back and retighten neck, temple

and forehead straps. The straps should be tightened firmly enough to prevent

movement on the face during use, but should not be overly tight. Excessive tightness

may lead to increasing discomfort during use. Check once again that there is no hair

under the face seal

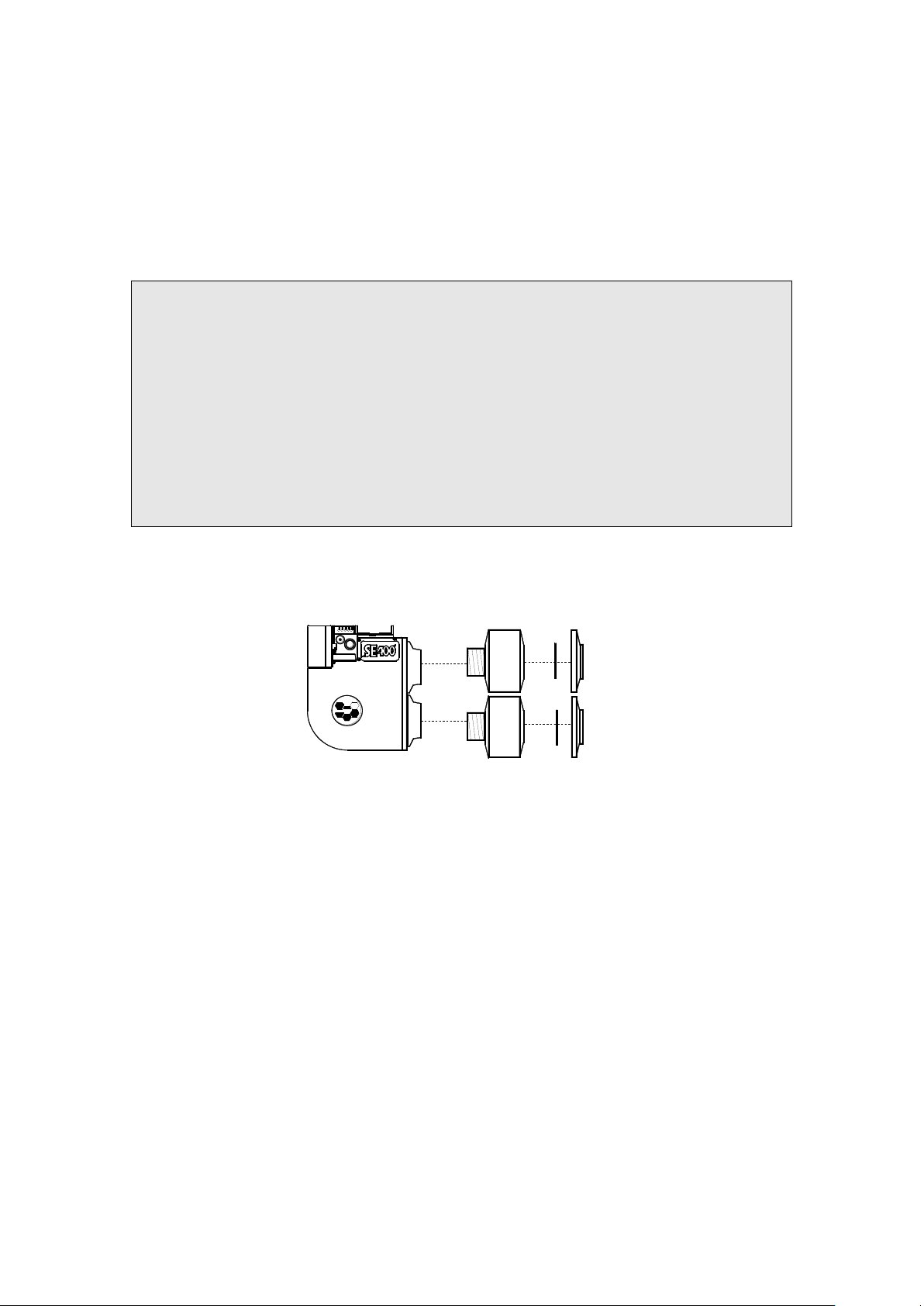

15. Rotate your head and check for comfortable,

free movement. Adjust hose swivel at mask

end as required.

16. Adjust the level of the speaker unit whilst

speaking

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 13

17. Check the warning light in front of the mask. It

should not be lit. The audible alarm should be

silent. If not, investigate. Do not enter a

contaminated area until it is resolved

18. Don any outer protective clothing as required.

You are now ready to enter a contaminated

area.

* Note: The User Seal Check is a simple check for gross leakage prior to use. It is not a

substitute for a quantitative fit test (QNFT).

Buddy Check

When entering a contaminated area in groups of two or more, it is good practice to perform a

“buddy check”. Pairs of users should visually inspect –but should not adjust –each other’s

respirators, checking for things like correct mask positioning, strap tightness, absence of hair

in the face seal, correct fitment of battery, hose and hose cover, filters and accessories, etc.

Check that the fan unit is operating correctly by observing the status lights panel on the fan

unit (refer to section Operation for further details).

Warning

If the facepiece has been properly donned and adjusted, detection of contaminant odour

or taste, or irritation of eye, nose or throat during use may indicate exhaustion of the

filtration media. Return to fresh air immediately without removing the respirator, check

facepiece fit and replace filtration media. Used filtration media should be disposed of

properly in accordance with state and/or local guidelines for disposal of contaminated

material.

(attach CD-ROM here)

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 14

WORKING IN A CONTAMINATED AREA

Before entering a contaminated environment, ensure that the SE400 is suitable for use in that

environment. Consult section Cautions and Limitations.

For information on the operation of the SE400, see section Operation.

Try to remain relaxed at all times. Breathe normally.

Do not over-exert yourself if you don’t have to. Reducing effort prolongs battery and

filtration media life.

Be aware of the SE400 warnings (facepiece warning light, audible alarm)

In the event of a malfunction of the SE400, do not panic. Leave the contaminated area

quickly but safely. Do not remove the facepiece from your face until you have

reached clean air and have been decontaminated. Remember that even without the

blower operating the SE400 continues to function as a negative-pressure APR and

gives considerable protection.

If you sense any of the following danger signals:

osmell or taste of contaminants

oeye, nose or throat irritation

obreathing difficulty

ouncomfortably warm breathing air

odizziness, nausea or vomiting

immediately leave the contaminated area. Do not remove the respirator until you

have reached clean air and have been decontaminated.

Be aware of the position of the breathing hose –take care to avoid catching on any

objects or obstructions in the work environment

Decontamination

After exposure in a contaminated environment, the respirator and the user may require

decontamination in order to prevent contamination of clean areas, and to prevent

contamination of and injury to the user and other personnel.

Decontamination procedures should be developed as part of the organisation’s respirator

program and should be appropriate to the hazards involved.

When developing a decontamination procedure, consider the following guidelines:

The SE400 is water-resistant. It is NOT waterproof! Never submerge the SE400 in

water.

Leave the speaker unit connected to the fan unit. This will protect the connector

terminals.

Do not remove the facepiece or turn off the blower until after initial decontamination.

After removing the facepiece, do not allow direct water streams inside the facepiece.

Water may enter the fan unit through the breathing hose and cause serious damage.

Do not use compressed air when cleaning. The SE400 contains sensors for measuring

facepiece pressure and ambient pressure that may be damaged.

Filtration media should always be discarded after decontamination in a shower.

Batteries can be decontaminated in a water shower. After doing so, shake off the

water and place it on a dry surface with the contacts downwards. Batteries should be

thoroughly dry before recharging.

The breathing hose may be fitted with a single-use chemically resistant cover. This

cover should be removed and discarded during decontamination. The breathing hose

should be decontaminated after the cover has been removed. A replacement cover

should be fitted ready for next use. Consult user instructions supplied with the hose

cover.

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 15

Do not disconnect the breathing hose from the facepiece or fan unit during

decontamination. If disconnected, water may enter and damage the respirator.

Note: Before decontaminating with a high pressure shower, it is advisable to remove the

prefilters, which may become waterlogged and block the airflow.

Note: All disposable contaminated material –such as filtration media, prefilters and

breathing hose covers –should be disposed of in accordance with state and local guidelines

for hazardous waste materials.

After decontamination, the SE400 should be prepared for reuse. This normally involves:

thorough cleaning of external surfaces. Do not use solvents on the SE400

visual inspection for condition and completeness

replacement or repair of components as required

recharging of battery(s)

performing a Self-Test

ensuring all parts are dry before storage

STORAGE AND TRANSPORT

The SE400 is designed to withstand harsh working conditions and inhospitable environments.

However, proper storage and transport methods will prolong the life of the respirator and

ensure it is always capable of optimum performance.

When storing or transporting the SE400, keep in mind the following points:

Store in clean and dry area

Store in ambient conditions between –20 and +55°C (–4 and +131°F) and less than

70% relative humidity. Battery may be stored at +55°C no longer than one month.

For longer term storage, consult section Battery care and maintenance.

Protect the respirator and components from potential hazards such as sharp edges,

heavy weights, abrasives, chemicals and moisture

Avoid sources of vibration

Do not store in direct sunlight

Gas filters should be stored in airtight containers at all times when not in use

Warning

Batteries in storage do not retain full charge indefinitely. Periodic recharging is necessary to

maintain full charge. Consult section Batteries for more information on charging and

maintaining batteries.

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 16

COMPONENTS OF THE SE400

Fan unit

The fan unit contains a centrifugal blower for drawing purified air from the canisters and

delivering it under pressure to the facepiece via the breathing hose. It is constructed from

rugged ABS plastic.

The fan unit has threaded connectors for attachment of filtration media.

The fan unit contains electronics that control the air delivery rate. It also has many advanced

functions such as warnings for filter end-of-life and filter missing, logging of important

operating data and real-time monitoring of facepiece pressure. It can be connected to a PC for

configuring the fan unit parameters and downloading operating data. Consult supplementary

manual, SE400 advanced functions.

The fan unit model number is located on the identification label on its underside.

Each filter position is fitted with an external thread, gasket and nut for connection to SE-

shield suits. Consult the SE-shield user instructions for use.

Note: The SE-shield suit-sealing nuts should remain fitted to the fan unit at all times, even

when not used with a suit, in order to protect the threads from damage.

Breathing hose

The breathing hose conveys purified air from the fan unit to the facepiece. It also links the

facepiece pressure detection, speech microphone and warning light to the fan unit. The

flexible hose is made from tough polyurethane.

The breathing hose should remain connected to the fan unit at all times.

The breathing hose model number is located on the attachment to the fan unit, and is not

visible when the hose is fitted to the fan unit.

SE-shield breathing hose

The SE-shield breathing hose is used in place of the standard breathing hose when the SE400

is used with SE-shield protective suits. The SE-shield breathing hose directs a small amount

of filtered air from the SE400 into the suit, maintaining positive pressure inside the suit. For

more information consult section SE-shield protective ensembles.

Facepiece

Full facepiece

The full facepiece is available in a single size to fit all faces. It is available in the following

materials:

Silicone rubber (RF3-FS) for maximum comfort in normal industrial use

Halo-butyl rubber (RF3-FP or RF3-FP-C) and chloroprene rubber (RF3-FC) for

applications where high chemical resistance is required

The full facepiece visor is available in the following materials:

High-clarity polycarbonate (standard)

Polycarbonate with hard coating for chemical and scratch resistance (standard on

RF3-FP-C, optional on others)

“Triplex” laminated glass for maximum chemical resistance (optional on all but RF3-

FP-C)

The demand valve regulates the air flow to the facepiece in response to the user’s breathing

requirements. It is made to S.E.A.’s patented design.

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 17

The full facepiece can be identified by the

markings:

“RF3” on demand valve attachment inside inner

mask

“FS”, “FP” or “FC” on mask body above visor.

“C” on corner of visor (RF3-FP-C only)

Note: If a good face fit cannot be achieved for a particular user, the S.E.A. Full Face Mask

Insert (SEA-FI) may be fitted to the mask to improve the fit. This should be done in

conjunction with a face fit testing program. See section Facepiece Fitting.

Half facepiece

The SE400 half facepiece is intended for use in general industrial environments. It consists of

a one-piece silicone facepiece attached to the demand valve.

The half facepiece is available in three sizes: Small (RH1-S), Medium/Large (RH1-M/L) and

Large (RH1-L).

Demand Valve

The demand valve is attached to the front of the facepiece. It should remain fitted to the

facepiece at all times other than for periodic thorough cleaning or if necessary for

maintenance.

The demand valve model number is located on the outer surface of the housing.

Filtration media

HE filters (particle filters)

High Efficiency (HE) filters (in USA) and particle filters Class P3 (including P1 and P2) (in

other countries) protect against all types of airborne particles such as dust, oil mist, smoke,

aerosols, bacteria, viruses and mould, with a separation level of more than 99.97%.

Particle filters Class P4 (including P1, P2 and P3) (in countries other than USA) provide

protection as per P3 filters but with a separation level of more than 99.997%.

Chemical cartridges (gas filters)

Chemical cartridges (in USA) and gas filters (in other countries) provide protection against

gases in concentrations up to 0.5 per cent by volume or 5,000 ppm. Refer to regulatory

guidelines.

Prefilters

Pre-filters are coarse particulate filters which prevent clogging or other contamination of the

main filtration media. Pre-filters should always be fitted to clip-in filtration media, and should

be replaced frequently.

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 18

The SEA prefilter (221) may be used with any SEA filter. Use prefilter holder PFH-T with

threaded filtration media, and prefilter holder 20062 with clip-in filtration media.

Approval of filtration media

Use only filtration media approved for use with the respirator. (USA) Consult the NIOSH

approval label supplied with the respirator and filtration media. (Europe and Australasia)

Consult the user instructions provided with the filtration media.

Note (USA): SE400 respirators with half facepieces do not provide CN/CS protection.

Warning

Only original SEA filtration media, approved for use with the SE400, may be used.

Chemical cartridges (gas filters) must never be used without HE filters (particle filters)

fitted.

Follow established canister change-out schedules to ensure canisters are replaced

before breakthrough occurs.

Incorrect fitment of filtration media may result in lost or reduced protection of the

SE400

The SE400 should be fitted only with matching filtration media –each filter should have the

same part number and age.

To fit threaded filtration media:

Note: Method for SE400AT-2 is shown. For SE46 use the same method but with three

filtration media.

1. Check that the filtration media are of the correct type and class (if unsure, check with

supervisor)

2. Check that the model number on the filtration media is correct and that the use-by

date has not expired

3. When using new filtration media, check that the sealed packaging is intact and

airtight

4. Remove the filtration media from the packaging

5. Check the filtration media for damage. Filtration media with visible physical damage

should be discarded immediately

6. Check that the threads on the filtration media and fan unit are clean and the gaskets in

the fan unit are clean, undamaged and properly seated

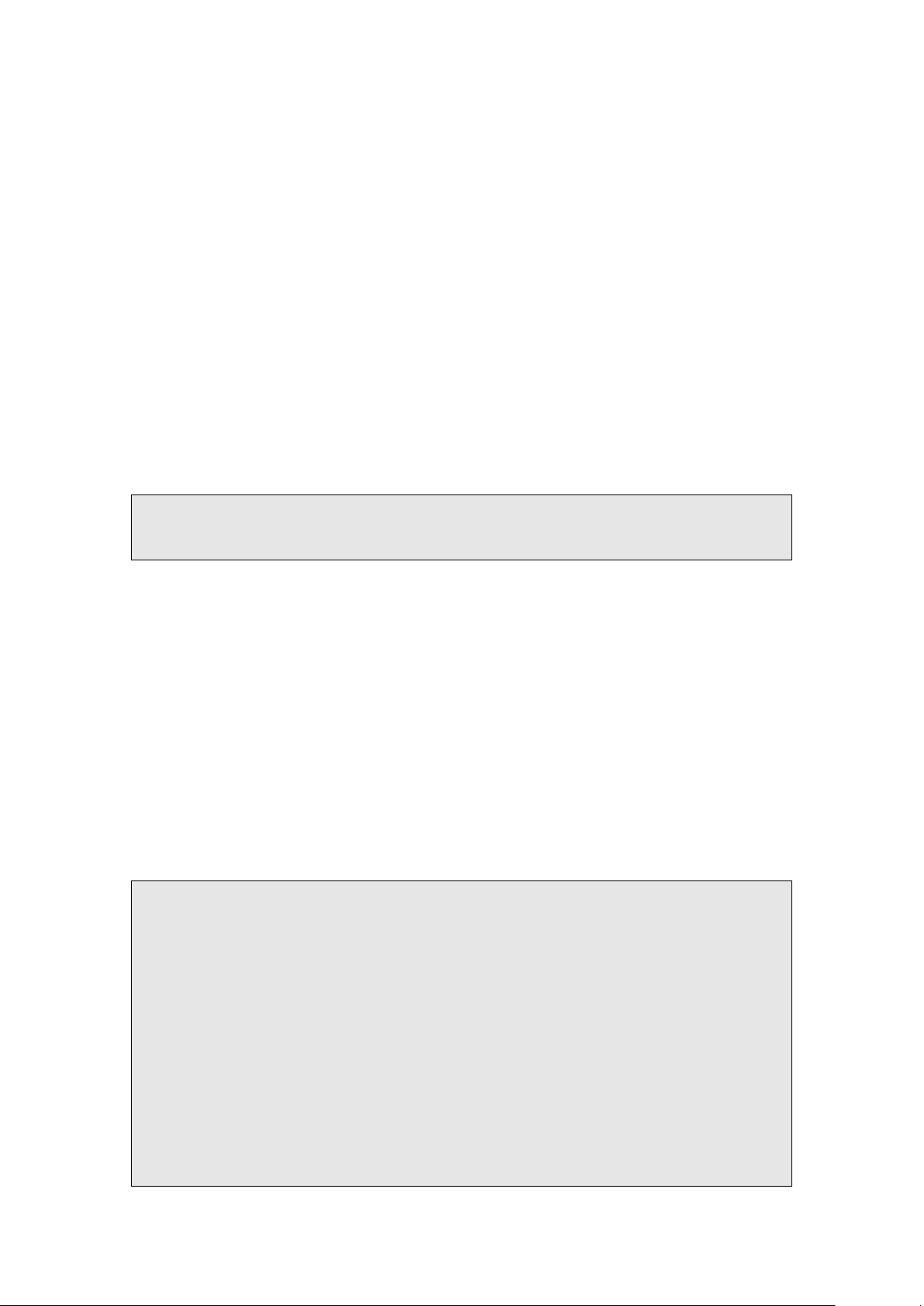

7. Screw each of the filtration media (1) into the fan unit and tighten firmly. Spin the

filter until it begins to tighten, then turn another 120º or so (slightly more than a

quarter turn). Take care not to overtighten. Note that the fan unit gasket has a self-

locking design, so the turning resistance will increase steadily as it is tightened

8. Fit prefilters (2) into prefilter holders (3) and snap them on to inlet of filtration media.

1

2

3

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 19

To fit clip-in filtration media using threaded filter adapters:

1. Fit threaded filter adapters TA1 or NR280-3 (4) to the fan unit as per steps 6 and 7

above

2. Attach the clip-in filtration media (1) to the adapters. Ensure that the arrows on the

labels point towards the fan unit. Make sure that the flanges of the filtration media sit

snugly into the rubber grooves in the adapters

3. Fit prefilters (2) into prefilter holders (3) and snap them on to the filtration media.

To remove the filtration media:

1. Simply unscrew and remove.

Batteries

The SE400 is powered by one or two rechargeable Nickel Metal Hydride (NiMH) batteries.

Batteries can be easily interchanged. If used and maintained correctly a battery will give a

service life of up to 500 charge/discharge cycles.

Single battery configuration

When used in single battery configuration, the battery is fitted directly to the SE400 fan unit.

Dual battery configuration

The Dual Battery Adapter is used to provide dual battery configuration for the SE400, giving

it extended operating time. See section Dual Battery Adapter.

Battery operating time

The operating time of the SE400 when fitted with fully charged battery or batteries greatly

depends on the workload of the user, in the same way that a motor vehicle’s fuel consumption

depends on the load, terrain and manner of driving.

Prolonged periods of high exertion and/or stress will significantly reduce the operating time.

In these situations the user can expect a shorter available working time in a contaminated

area.

NIOSH has certified the operating time of the SE400 at 4 hours minimum, in both single and

dual battery configurations, under standard test conditions (38 litres per minute) when tested

on a breathing machine (USA).

Warning

The above operating times are not guaranteed in real situations. Actual operating times may

be significantly longer or shorter, depending on working conditions.

SE400 user instructions —600006 N

Copyright © 2019 by The S.E.A. Group 20

Note: Operating time is affected by the following:

Conditions of use. High breathing rates will result in reduced operating time.

Level of charge of battery(s). Only fully charged batteries should be fitted to the

SE400 before use.

Battery condition. Batteries degrade over their working lives. A battery nearing the

end of its life will have a reduced capacity. A battery should be replaced when the

operating time has reduced significantly.

Battery temperature. Towards the upper end of the operating temperature range of

the SE400 battery performance diminishes only slightly. At battery temperatures

below 5°C (41°F) , capacity diminishes sharply. Allow batteries to cool after

charging and before use.

Low battery warning

The SE400 gives a series of audible and visible warnings as the end of operating time

approaches. The first low-battery warning occurs approximately 5 minutes before the SE400

shuts down. The warning time is independent of the operating conditions.

Note: The SE400 provides full breathing performance at all times until the fan unit shuts

down due to low battery level.

Warning

Old batteries in poor condition may cause the low battery warning time to be reduced.

Battery care and maintenance

Batteries in storage do not retain full charge indefinitely. Periodic recharging is recommended

to maintain full charge.

Never allow a battery to become fully flat whilst in storage. A fully discharged battery may

suffer permanent degradation over time.

Ideally, batteries should be stored in the temperature range 10 to 25°C (50 to 77°F) to

minimise degradation during long-term storage.

Batteries in long-term storage should be recharged at least once per year, and preferably every

six months, to minimise degradation.

Optimum battery condition is maintained by storing batteries in the Gang Battery Conditioner

(GBCO) (not supplied with the SE400 respirator). When stored in the GBCO, batteries

receive regular conditioning cycles and are maintained in ready-to-use condition, with close

to full charge. Consult the user instructions provided with the GBCO.

Warning

If handled incorrectly, NiMH batteries can leak toxic electrolyte, and in some circumstances

explosion may occur. Be sure to observe the following safety precautions:

Never disassemble a battery

Never short-circuit the terminals of a battery. Do not carry or store a battery with other

metal objects as short-circuiting may result

Never heat a battery or dispose of it by fire. Leakage and explosion may result

Never leave a battery exposed to direct sunlight, or close to a source of heat, for

extended periods whilst not in use

Never immerse a battery in water or other liquid

The battery is designed specifically for the SE400 range of respirators. Do not

attempt to use it to power any other equipment.

Table of contents

Other S.E.A. Group Respiratory Product manuals