Page # 3

877 1st Ave. N.W. | Sioux Center, IA 51250 | Toll Free: 1.866.722.1488 | siouxautomation.com

OPERATION

REPLACEMENT PARTS

READ complete manual CAREFULLY

BEFORE attempting operation.

877 1st Ave. N.W. | Sioux Center, IA 51250 | Toll Free: 1.866.722.1488 | siouxautomation.com

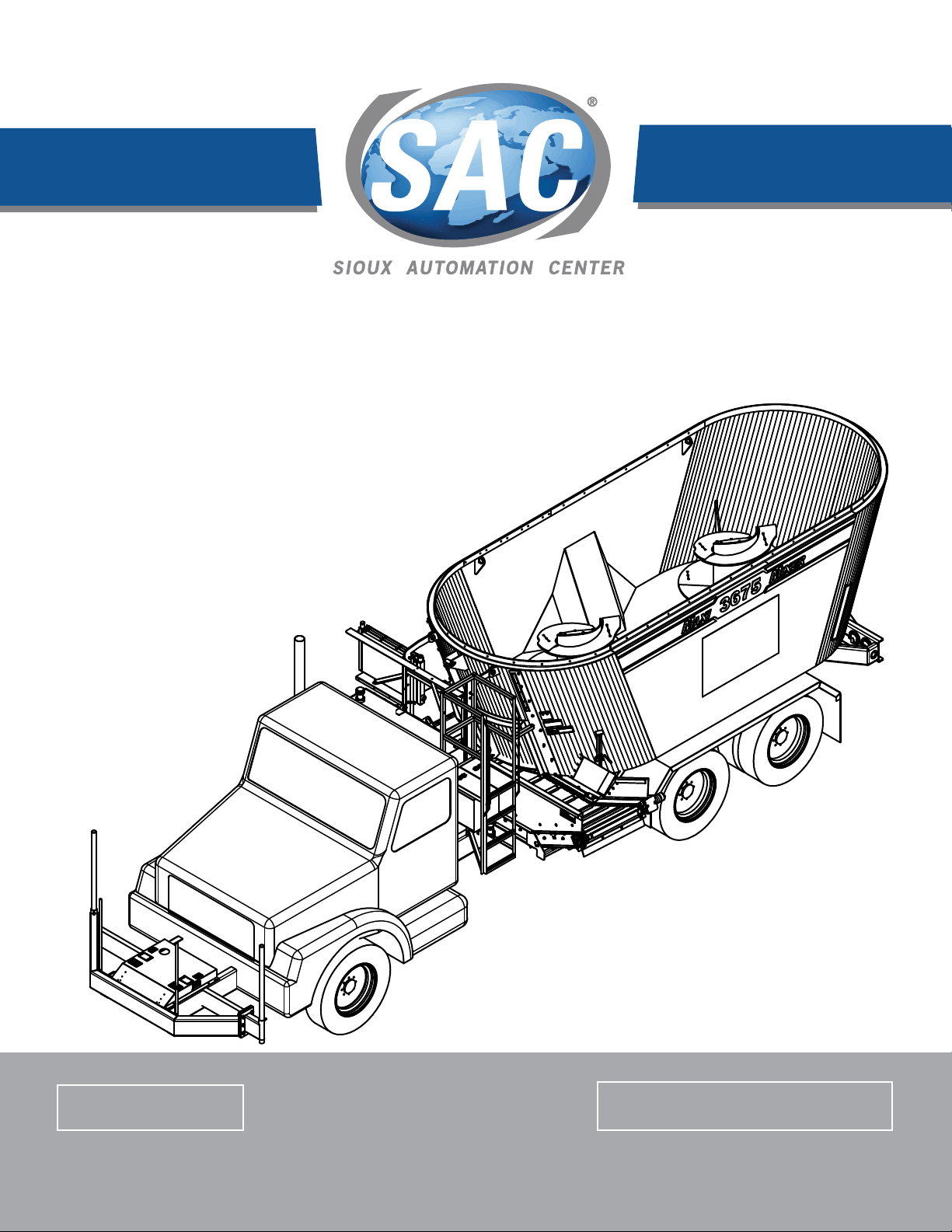

OPERATION

REPLACEMENT PARTS

READ complete manual CAREFULLY

BEFORE attempting operation.

Introduction, General and Contact Information,..........................................................................................................................................4

Customer Reference Information.......................................................................................................................................................................5

Safety Symbols and Signal Words ......................................................................................................................................................................6

Guidelines, Lighting and Marking......................................................................................................................................................................7

Safety Sign Care, Sign Locations......................................................................................................................................................................8-12

Hydraulic, Maintenance .......................................................................................................................................................................................13

Tire Safety, Before Operation ............................................................................................................................................................................14

During Operation ..................................................................................................................................................................................................15

Following Operation, Transport Operations..................................................................................................................................................16

Following a Maintenance Schedule ...............................................................................................................................................................17

Performing Maintenance......................................................................................................................................................................................17

Bolt Torque Data ......... ...........................................................................................................................................................................................18

Pre-Operation Checklist, Hydraulic Pump System ......................................................................................................................................19

Control Console & Display................................................................................................................................................................................ 20-46

Electrical Kits .........................................................................................................................................................................................48-53

Hydraulic Reservior ...............................................................................................................................................................................................54

Front Door Discharge ...........................................................................................................................................................................................55

Troubleshooting .......... .......................................................................................................................................................................................56-57

Mixer Set-up ............................................................................................................................................................................................................58

Mixer Operation ...................................................................................................................................................................................................59-63

Inspection and Adjustments...............................................................................................................................................................................64

Fluids and Lubricants ...........................................................................................................................................................................................65

Conveyor Lubrication and Maintenance .....................................................................................................................................................66-67

Auger Maintenance ............................................................................................................................................................................................68

Hydraulic Filtration ........... ..................................................................................................................................................................................69-72

Hydraulic Cooling System....................................................................................................................................................................................73

Hydro and Auxiliary Hydraulic Assemblies ................................................................................................................................................74-98

Final Assembly .....................................................................................................................................................................................................99-101

Machine Mounts ....................................................................................................................................................................................................102

Discharge Door Assembly...................................................................................................................................................................................103

Restrictor Blade, Viewing Window ...................................................................................................................................................................104

Auger Assemblies ..................................................................................................................................................................................... 105-106

Replacement Auger Installation ......................................................................................................................................................................107

Knife Assemblies ...........................................................................................................................................................................................108

Rear Discharge Door Assembly ........................................................................................................................................................................109

Discharge Assemblies .....................................................................................................................................................................................111-116

Magnetic Deector ................................................................................................................................................................................................117

Rear Bumper and Light Assembly....................................................................................................................................................................119

Front Bumper Assemblies ..............................................................................................................................................................................121-121

Driveline Assemblies .............................................................................................................................................................................................122

Scale Kits ...................................................................................................................................................................................................................123

Remote Control Kit ...........................................................................................................................................................................................124

Remote Camera Kit ...........................................................................................................................................................................................125

Extension Kits ...........................................................................................................................................................................................126

Maxi-Mixer Specication Chart ........................................................................................................................................................................127

Maintenence Record .......................................................................................................................................................................................129-131

Warranty ................................. .................................................................................................................................................................................132

Scale Warranty ........................................................................................................................................................................................................133

TABLE OF CONTENTS