4XL-FW10009UM-en-US Rev F · 2021-06-16 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND,

HOLLAND, SAF, and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

MADE IN XXXXX

SCAN QR CODE FOR PRODUCT INFORMATION

Model No. XXXXXXXXXXXXXXX

Serial No. XXXXXXXXXXXXXXX

U.S. AND FOREIGN PATENTS APPLY Ph: (888) 396-6501 or 52.1.55.5456.8641

CONSULT PRODUCT INFORMATION AT

LITKITS.SAFHOLLAND.COM PRIOR TO USING

THIS PRODUCT. FAILURE TO PROPERLY INSTALL,

MAINTAIN & OPERATE THIS PRODUCT COULD RESULT IN TRACTOR

TRAILER SEPARATION CAUSING SERIOUS INJURY OR DEATH.

QR

CODE

Model Identification

Figure 4

Figure 3

Figure 2

Figure 1

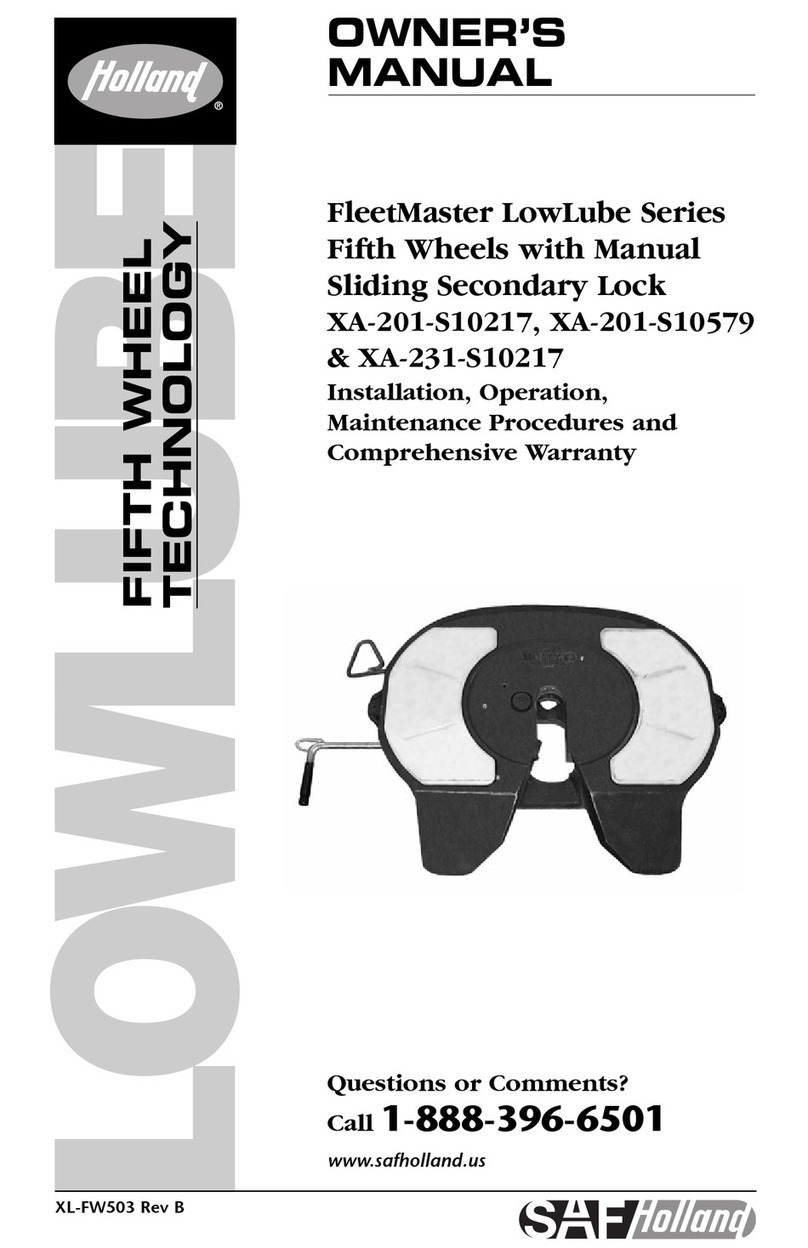

2. Model Identification

The fifth wheel serial tag is located on the

handle side of the fifth wheel top plate

near the pickup ramps (Figure 1).

The fifth wheel model number and serial

number are listed on the tag (Figure 2).

3. Decal Requirements

Decal XL-FW350 (Figure 3) enclosed in

the plastic bag with the Owner’s Manual,

MUST be installed near the fifth wheel and

easily viewed by the operator. Place the

decal on a flat surface such as the frame

rail or on the back of the cab (Figure 4).

NOTE: Ensure that the surface is clean

(free of oil and grease) before

applying the decal.

It is the responsibility of the end user to

periodically inspect the decal and ensure

that it is clean and completely legible.

If the label is missing, loose, damaged or

difficult to read, contact SAF-HOLLAND

Customer Service at 888-396-6501 to

order replacements immediately.

2.Nogap

Sinseparación

Pasd’espacement

WARNING/ ADVERTENCIA / AVERTISSEMENT

ALWAYSinspectfifth wheel

aftercouplingtractor to trailer.

Failuretoproperly couple the

tractorandtrailer could result in

tractor-trailerseparationwhile in

usewhich,if not avoided, could

resultindeath or serious injury.

CORRECTCOUPLING / ACOPLAMIENTO CORRECTO / ACCOUPLEMENT CORRECT

1.Nutandwasher snug against fifth wheel.

Tuercayarandelaajustadas contra la

quintarueda.

Écrouetrondelle

serréscontre

lasellette.

3.Lockscompletelyclosed around kingpin.

Seguroscompletamentecerradosalrededor

delpernorey.

Mâchoires

complètement

ferméessur

lepivot.

SIEMPREinspeccionela quinta

ruedadespuésde acoplar el

tractocamiónalremolque.

Sinoacopla adecuadamente el

tractocamiónyelremolque, podría

ocasionarlaseparación del

tractocamiónyelremolque durante

eluso,locual, si no se evita, podría

causarmuerteso lesiones graves.

TOUJOURScontrôlerla sellette

d’attelageaprèsavoir accouplé

letracteurà la remorque.

Unmauvaisaccouplement de la

remorquesurletracteur peut résulter

enuneséparationdu tracteur et de la

remorquesusceptiblede provoquer

lamortou des blessures graves.

Copyright©2012•SAF-HOLLAND, Inc.

www.safholland.us

2. No gap

Sin separación

Pas d’espacement

WARNING / ADVERTENCIA / AVERTISSEMENT

ALWAYS inspect fifth wheel

after coupling tractor to trailer.

Failure to properly couple the

tractor and trailer could result in

tractor-trailer separation while in

use which, if not avoided, could

result in death or serious injury.

CORRECT COUPLING / ACOPLAMIENTO CORRECTO / ACCOUPLEMENT CORRECT

1. Nut and washer snug against fifth wheel.

Tuerca y arandela ajustadas contra la

quinta rueda.

Écrou et rondelle

serrés contre

la sellette.

3. Locks completely closed around kingpin.

Seguros completamente cerrados alrededor

del perno rey.

Mâchoires

complètement

fermées sur

le pivot.

SIEMPRE inspeccione la quinta

rueda después de acoplar el

tractocamión al remolque.

Si no acopla adecuadamente el

tractocamión y el remolque, podría

ocasionar la separación del

tractocamión y el remolque durante

el uso, lo cual, si no se evita, podría

causar muertes o lesiones graves.

TOUJOURS contrôler la sellette

d’attelage après avoir accouplé

le tracteur à la remorque.

Un mauvais accouplement de la

remorque sur le tracteur peut résulter

en une séparation du tracteur et de la

remorque susceptible de provoquer

la mort ou des blessures graves.

Copyright © 2012 • SAF-HOLLAND, Inc.

www.safholland.us