2XL-AS20015BM-en-US Rev B · 2019-09-05 · Amendments and Errors Reserved · © SAF-HOLLAND, Inc., SAF-HOLLAND, HOLLAND, SAF,

and logos are trademarks of SAF-HOLLAND S.A., SAF-HOLLAND GmbH, and SAF-HOLLAND, Inc.

Contents

Introduction

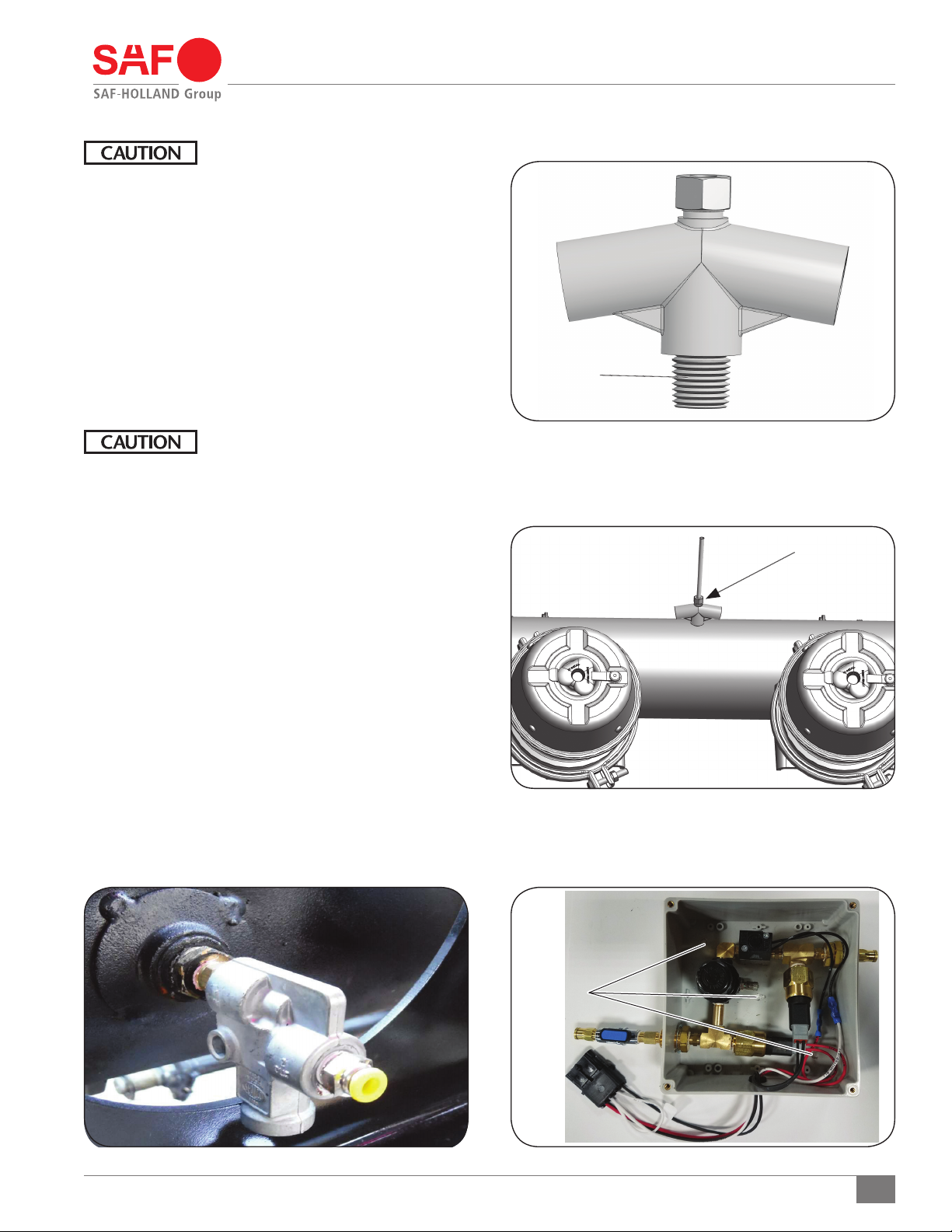

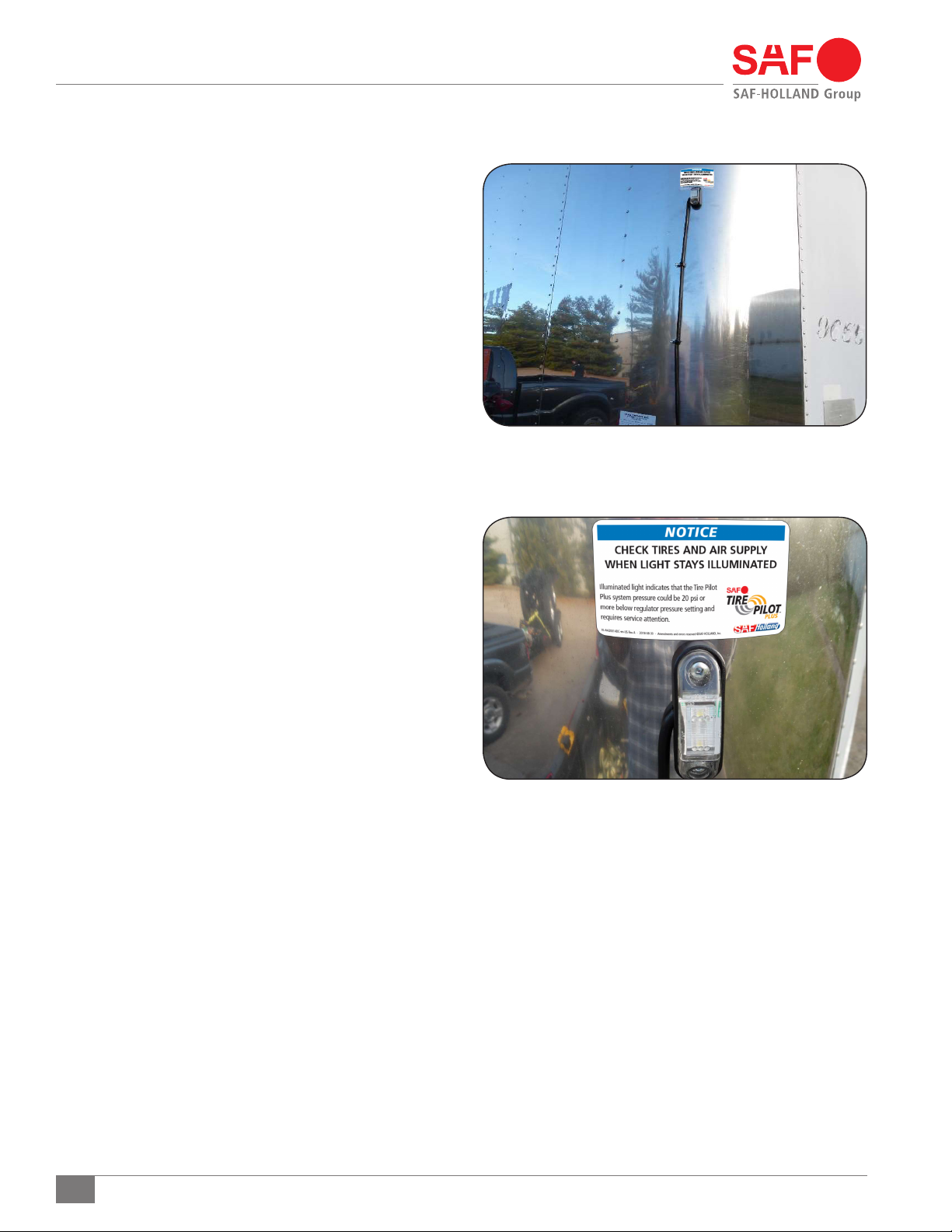

This manual provides information necessary for the installation

of the SAF-HOLLAND Tire Pilot Plus tire inflation system.

The Tire Pilot Plus uses air drawn from the tractor to pressurize

the system.

Read this manual in its entirety before installing this product.

Updates to this manual, which are published as necessary, are

available on the internet at www.safholland.us.

When replacement parts are required, SAF-HOLLAND highly

recommends the use of only SAF-HOLLAND Original Parts. A

list of technical support locations that supply SAF-HOLLAND

Original Parts and an Aftermarket Parts Catalog are available

on the internet at www.safholland.us or contact Customer

Service at 888-396-6501.

Warranty

Refer to the complete warranty for the country in which the product

will be used. A copy of the written warranty is included with the

product or available on the internet at www.safholland.com.

Notes, Cautions, and Warnings

Before starting any work on the unit, read and understand all

the safety procedures presented in this manual. This manual

contains the terms “NOTE”, “IMPORTANT”, “CAUTION”, and

“WARNING” followed by important product information. These

terms are defined as follows:

NOTE: Includes additional information to enable accurate

and easy performance of procedures.

IMPORTANT: Includes additional information that

if not followed could lead to hindered

product performance.

Used without the safety alert symbol,

indicates a potentially hazardous

situation which, if not avoided, could

result in property damage.

Indicates a potentially hazardous

situation which, if not avoided, could

result in minor or moderate injury.

Indicates a potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Contents Page

Introduction......................................................................... 2

Warranty.............................................................................. 2

Notes, Cautions, and Warnings ............................................. 2

Section 1 – General Safety Instructions ................................ 3

Section 2 – Tire Pilot Plus Identification................................ 4

Contents Page

Section 3 – Installation Instructions ..................................... 9

Section 4 – Multi-Axle Trailer Installation........................... 11

Section 5 – Performance Testing......................................... 11

Section 6 – Troubleshooting ............................................... 12