SG360-ISM-004 | REV F

1

Table of Contents

General Warnings …………….……………………….……..………………………………………………………………………………..2

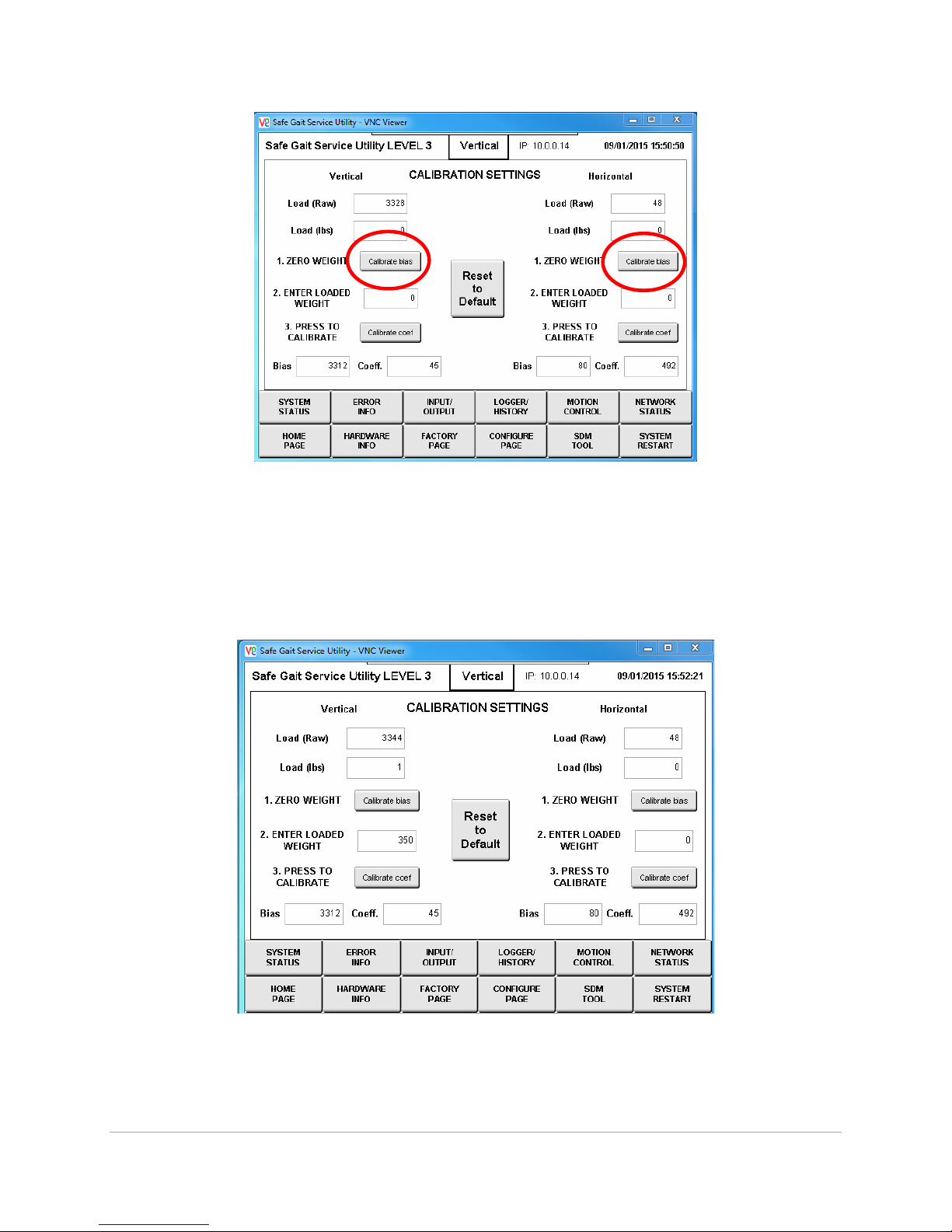

Load Cell Recalibration................................................................................................................................. 3

Logging out of the SafeGait application kiosk .......................................................................................... 3

VNC service interface .............................................................................................................................. 4

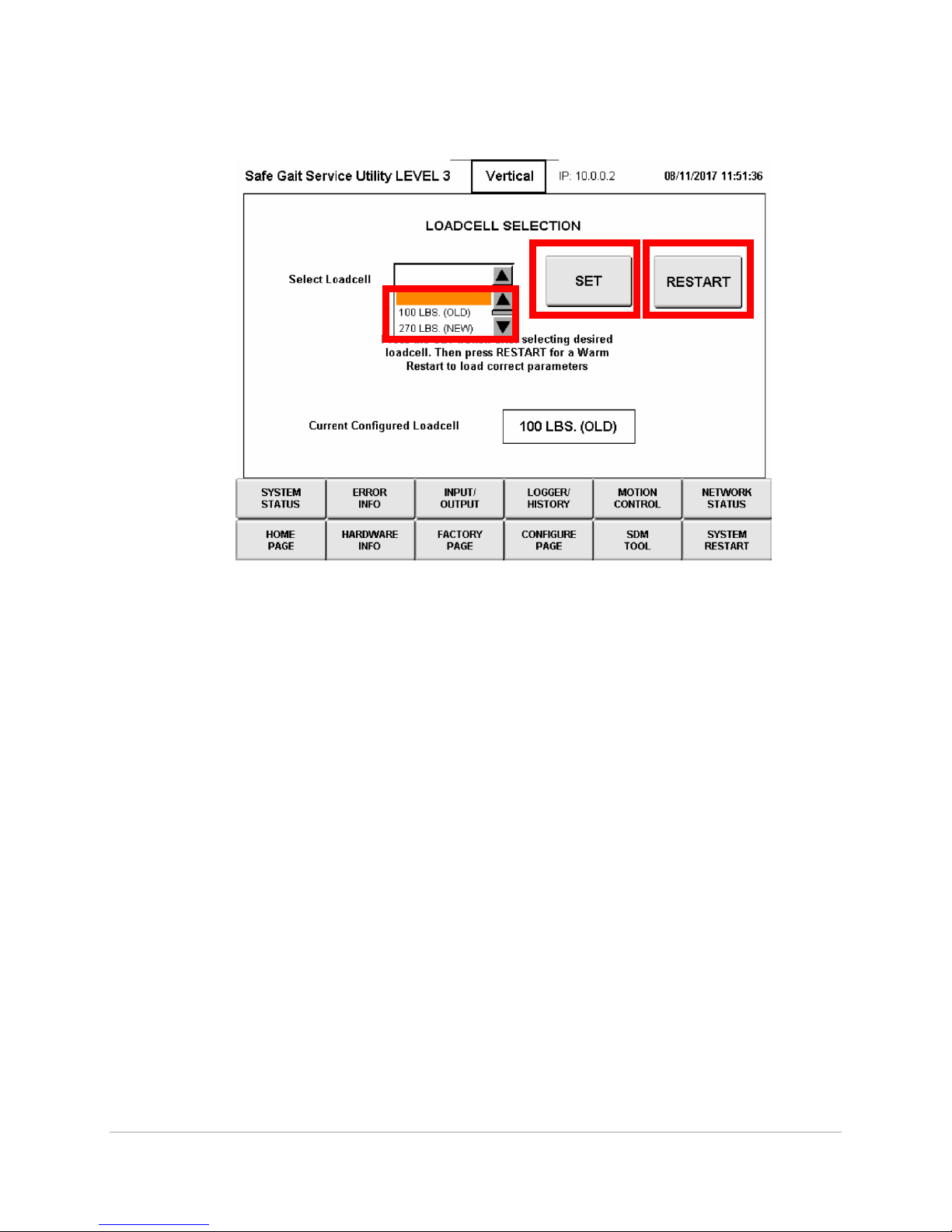

Selecting load cell .................................................................................................................................... 8

HMI battery change procedure ................................................................................................................. 10

Opening the SafeGait covers................................................................................................................. 11

Procedure for battery change .............................................................................................................. 13

Replace Trolley Wheel Block Assembly .................................................................................................... 14

Replace Strap Assembly ............................................................................................................................ 15

Setting Rotary limit switch ..................................................................................................................... 24

Actuator Check out Test ............................................................................................................................ 26

SafeGait Wiring Diagrams ......................................................................................................................... 27

Facility Panel Wiring Diagrams ................................................................................................................. 42

WIFI Ping Test ............................................................................................................................................ 47

Power Panel Green LED Replacement ...................................................................................................... 49

Version 4.0.1 Software install ................................................................................................................... 51

Data backup ............................................................................................................................................ 52

CF Card update to Version 3.1.1 ............................................................................................................. 53

Kiosk Laptop/Tablet (V4.0.1) Windows 10.............................................................................................. 56

Kiosk Laptop/Tablet (V4.0.1) Windows 8................................................................................................ 62

Remote/Handheld Android 5.1............................................................................................................... 68

Remote/Handheld Android 6.1............................................................................................................... 69

Router upgrade ....................................................................................................................................... 70

WIFI adaptor upgrade ............................................................................................................................. 73

NAS upgrade ........................................................................................................................................... 75

Linear Bearing Replacement ..................................................................................................................... 78

4 Pole hanger replacement ...................................................................................................................... 82

Conductor shoe replacement .................................................................................................................. 83