IMPORTANT PRE-INSTALLATION NOTES

Please read the entire Installation Manual carefully before

beginning the installation process. Also refer to the Product

Warranty and Disclaimers on the final page of the manual.

Remove all parts from the carton and, referring to Parts (next

page), ensure that all parts are included prior to installation.

If parts are missing, contact Safety Rail Source at

877.723.3766, 7:30am to 7:30pm EST, Monday – Friday.

The NextGen Lift & Lock Roof Hatch Opener can be installed by

one person, but it is more efficiently installed with two

people. The estimated installation time is 1½ to 2 hours.

Because much of the NextGen Lift & Lock Roof Hatch

Opener is installed at various points on the roof access

ladder, a climbing helmet and climbing harness or fall

protection gear are required for the installer. Hard hats are

also required for any additional installers working under the

ladder.

The NextGen Lift & Lock Roof Hatch Opener is designed for

ladders that meet Occupational Safety and Health

Administration (OSHA) standards, which recommend that the

ladder be 18” wide and that rungs be 12” apart. The system can

be installed on nonstandard ladders, but the installation

process will be somewhat different and installation might take

longer than anticipated for standard ladders.

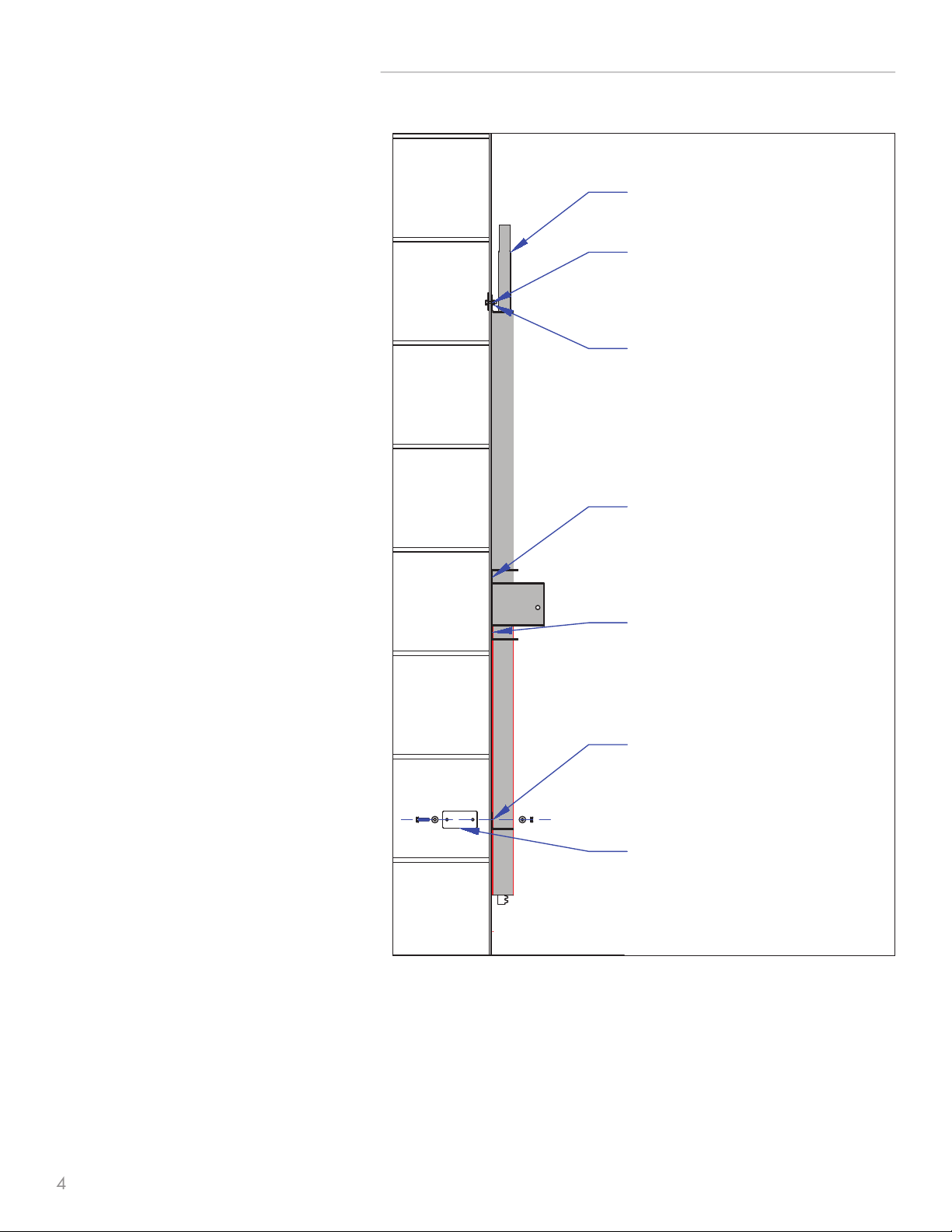

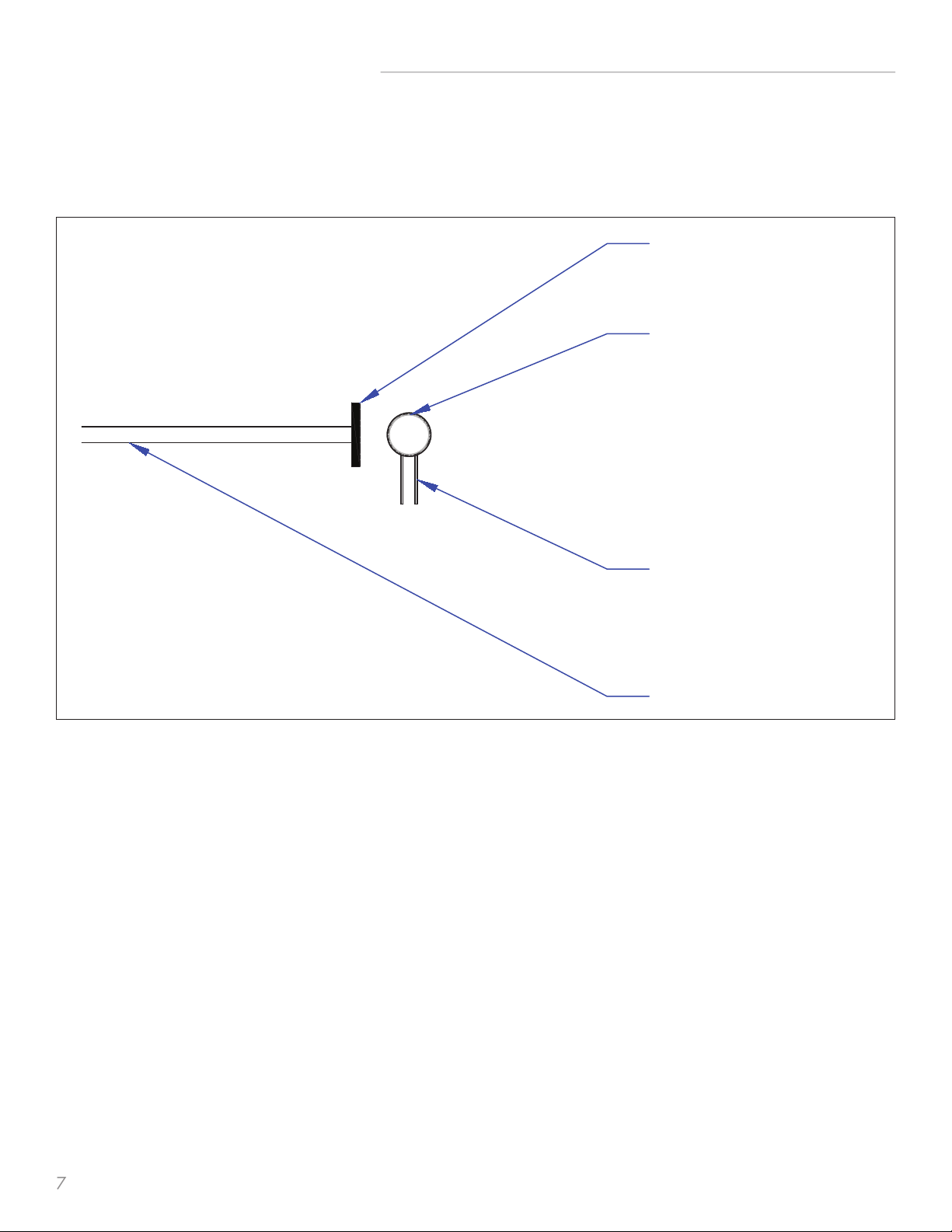

The ideal height for the winch handle that operates the

system is about 42” above the floor. This means that, on a

standard ladder, the winch portion of the Drive Unit should

be placed between the third and fourth ladder rungs. For a

nonstandard ladder, the installer can adjust the Drive Unit

location to the optimum height by moving the unit up or down

as needed to have the top and bottom bracket locations clear

of rungs (the top and bottom brackets are 5’ apart, so if one

bracket is clear of interference by a rung, they both should be).

The winch housing, which is part of the Drive Unit, has two

available mounting positions, at least one of which should be

clear of a rung and which should be used to attach the unit to

the ladder. It is not necessary to use both of these winch

housing mounting points.

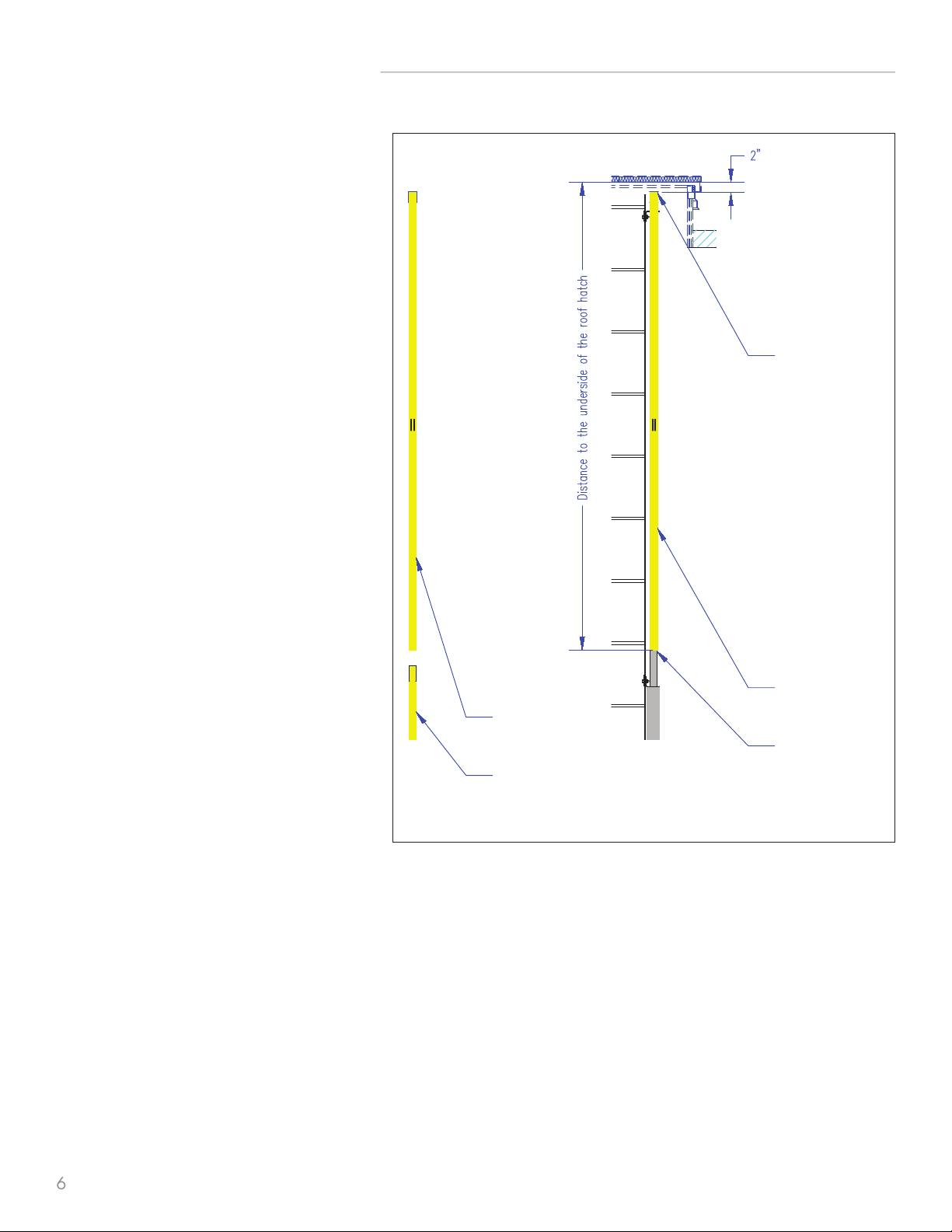

Each NextGen unit is manufactured using dimensions

provided by the buyer; therefore, the unit should fit with only

minor adjustments. The standard NextGen unit, which includes

the Drive Unit and the Lifting Tube, has a fully assembled height

of 13’-6” (162”). In the event that the hatch is more than 15’

from the floor, the necessary Lifting Tube Extension (or

Extensions) is included.

NextGen Lift & Lock Installation Manual 01.2021

TOOLS AND MATERIALS REQUIRED FOR INSTALLATION*

•Climbing helmet

•Climbing harness or fall protection harness

•Hard hat

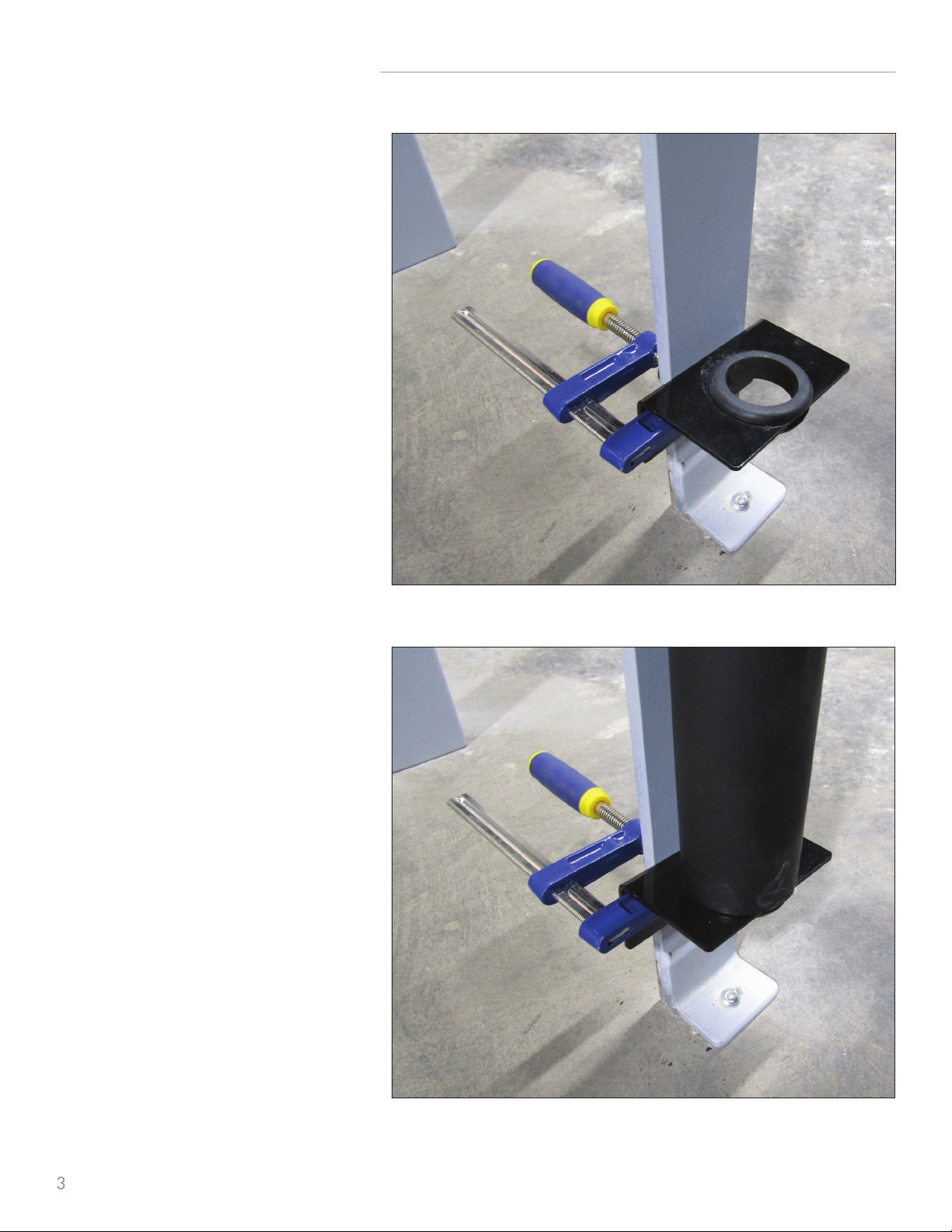

•Two 6” or approximate clamps

•Two 7/16” box wrenches or sockets

•Drill with 1/8” bit

•3/4” wrench or adjustable wrench

•Two 9/16” box wrenches or sockets

•5/16” nut driver

•Blind rivet tool (optional)

•Tape measure

•Felt tip or other marker

•A-frame ladder (optional, if space allows and if

installer would prefer to work beside rather than on

the roof access ladder)

*Not included

2570 Blvd. of t

he Generals, Suite 200, Norristown, PA 19403 | [email protected] | 877.723.3766 | www.SafetyRailSource.com