Kee Klamp, Kee Lite, Kee Stainless, KeeGuard, Kee Dome, Kee Hatch, Kee Mark, Kee Access, KwikKit, Kee Anchor, Weightanka, Wireanka, KeeLine, Kee Walk and Kee Projects are all registered trademarks of Kee

Safety Ltd, Beam Clamp, and Box Bolt are all registered trademarks of Access Technologies Ltd, a subsidiary of Kee Safety International Ltd. While every effort has been made to ensure the accuracy of the

information contained in this brochure, Kee Safety, Inc cannot be held responsible for any errors or omissions. Kee Safety, Inc reserves the right to alter or withdraw products without prior notice.

Kee Safety, Inc does not accept responsibility for any loss or damage arising from improper use of its products.

Copyright 2011 Kee Safety, Inc. All Rights Reserved.

SPECIFIC LIMITATIONS.

PLEASE NOTE. The ‘wobble’ evident in an individ-

ual upright assembly is necessary for manufac-

ture and installation, and disappears when the

installation is complete.

The standard system model KDH is designed as a

complete unit, and should not be used with gates

or openings. Specic versions are available if ac-

cess points are required.

Do not use Kee Dome for attaching safety lines /

wires, lanyards or use as fall protection anchoring

point.

Components that are, or appear to be, modied

or damaged / defective must not be used.

Components should be positioned to minimize

any collection & retention of rainwater around set

screws

Do not mix Kee Klamp® components with any

other brands.

MAINTENANCE REQUIREMENTS.

In the event of impact or apparent damage, the Kee Dome system must be checked and any damaged items

replaced with Kee Safety original parts. Without such an occurrence the system must be checked annually

to ensure no damage has been sustained, and that set screws are to the correct torque.

TRANSPORTATION AND STORAGE.

There are no particular limitations as to transportation and storage of components other than they should

be kept in a dry and ventilated environment.

ALWAYS REFER TO AUTHORIZED KEE SAFETY, INC. PRODUCT LITERATURE OR TO THE WEB-

SITE (www.keesafety.com) FOR FURTHER INFORMATION ON THE USE OF COMPONENTS

AND THEIR ASSEMBLY AND INSTALLATION. IF YOU HAVE ANY QUESTIONS, ASK KEE SAFETY

OR YOUR LOCAL AUTHORIZED DISTRIBUTOR.

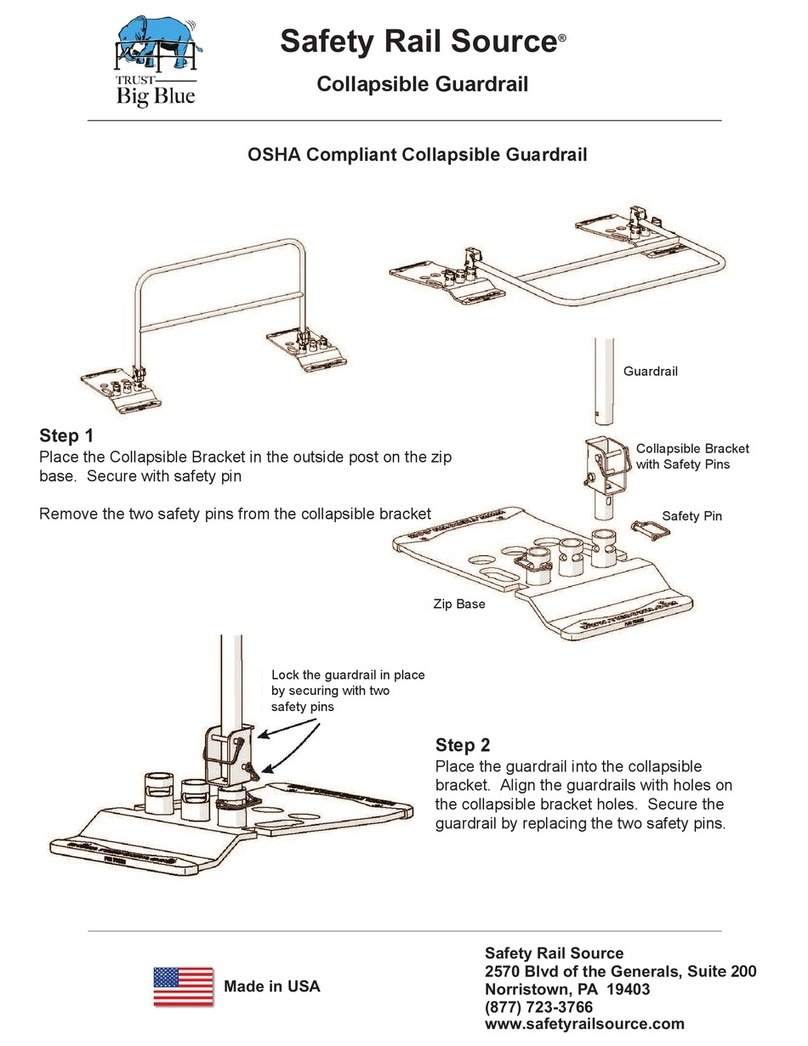

Fig. 2

A clamping ring is inserted

into the base unit to lock

the upright

75-8

250-8

Fig. 1

Kee Dome is 8’ x8’

model shown