Contents

1General Warnings................................................................................................. 4

2Application ............................................................................................................ 5

3Scope of Delivery.................................................................................................. 5

3.1 Standard:................................................................................................................... 5

3.2 Accessories (Optional):............................................................................................. 5

3.3 Spare parts:............................................................................................................... 5

3.4 Software (Optional):................................................................................................... 5

4Connections and user interface........................................................................... 6

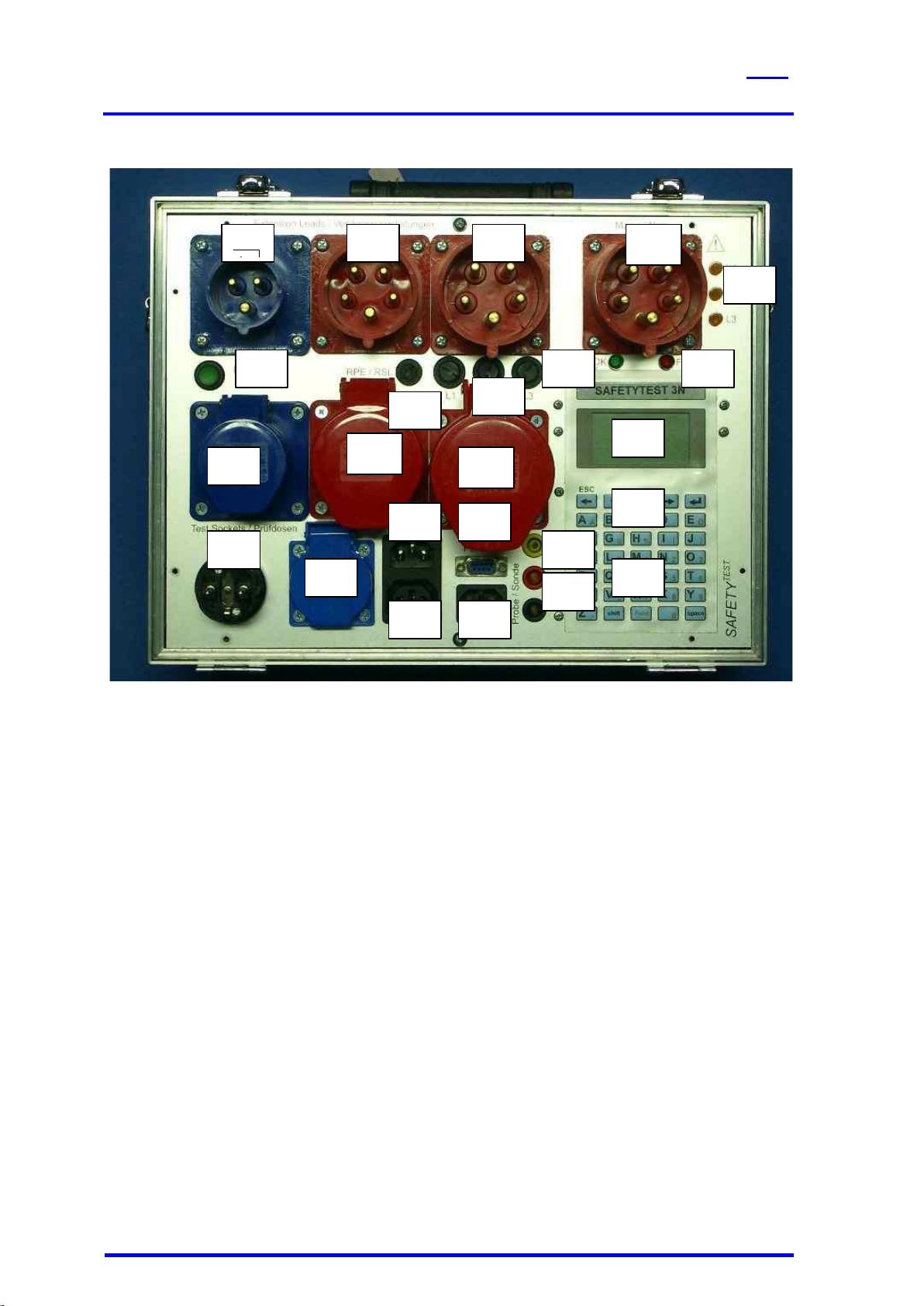

4.1 Connections (Picture 2) ............................................................................................. 7

4.2 Mains connection “Input“, Type CEE-32A 230/400V AC (Picture 2/1)........................ 7

4.3 Measuring socket “GND“ (Picture 2/16) .................................................................... 7

4.4 Measuring sockets “Probe“ (Picture 2/17) .................................................................. 7

4.5 Interface PC-COM (Picture 2/18)............................................................................... 7

4.6 Test sockets (Picture 2/2,3,4) ................................................................................... 7

4.7 Testing plugs (picture 2/5,6,7).................................................................................... 7

4.8 Fuses F1, F2 and F3 for all 16A testing sockets (picture 2/23)................................... 8

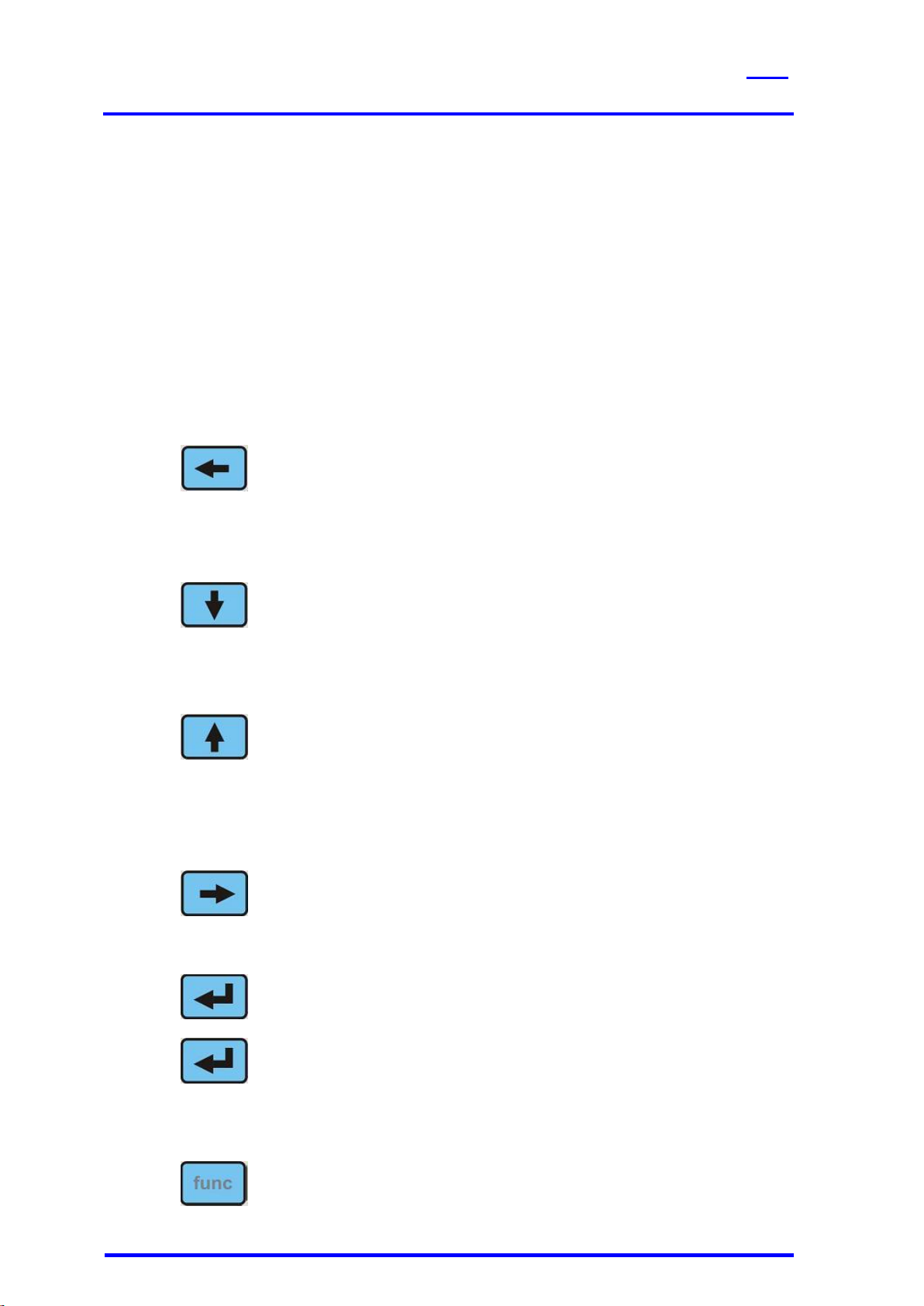

4.9 Keyboard................................................................................................................... 8

4.10 Display (Picture 2/14)................................................................................................. 8

4.11 Keyboard (Picture 2/15)............................................................................................. 8

5Functional Description......................................................................................... 9

5.1 Power supply............................................................................................................. 9

5.2 Internal memory......................................................................................................... 9

5.3 Interface RS232......................................................................................................... 9

5.4 Display and Keyboard................................................................................................ 9

5.5 Fuses......................................................................................................................... 9

6Testing the Mains Connection ............................................................................10

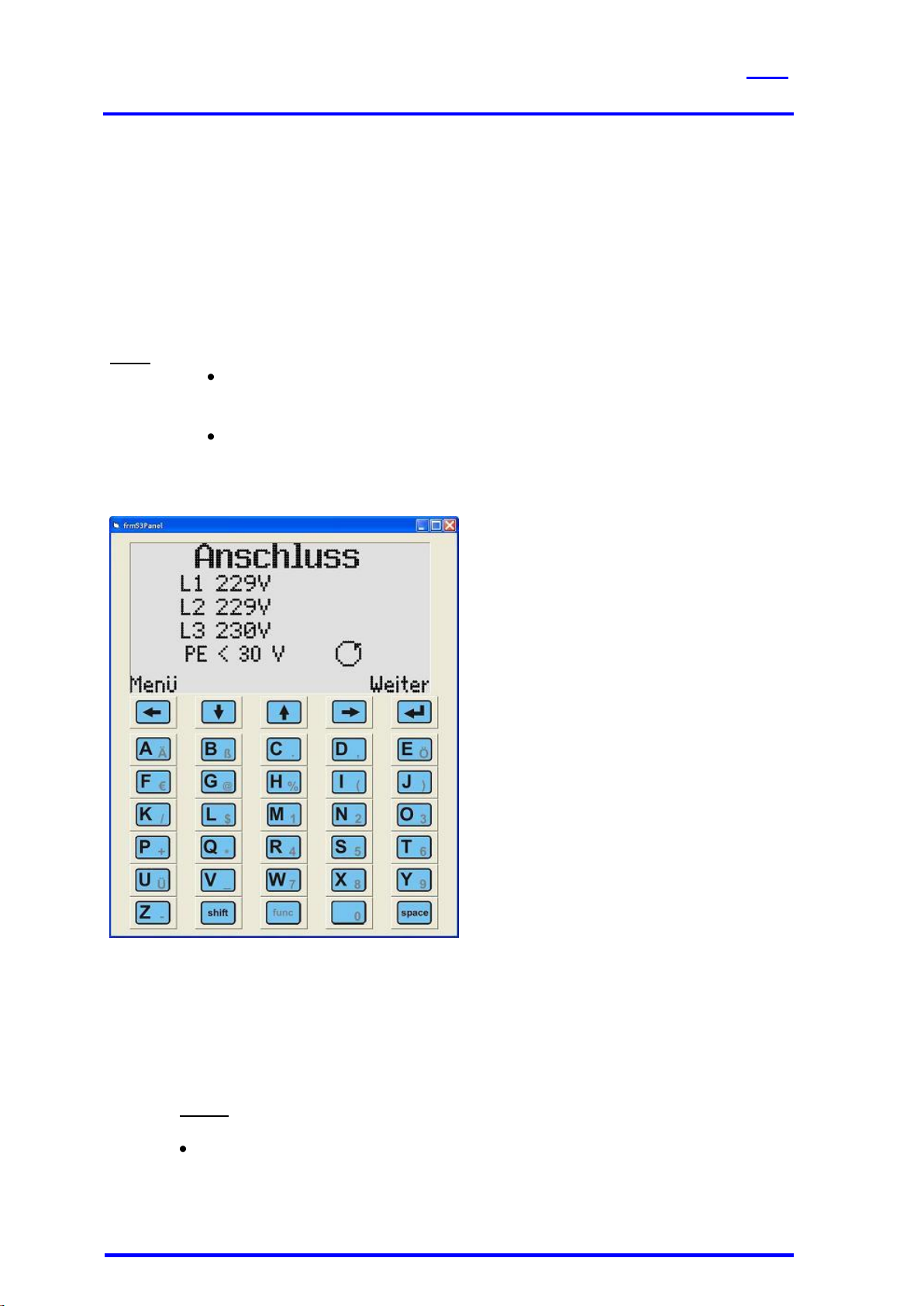

7Connection test....................................................................................................10

7.1 AC Supply.................................................................................................................10

7.2 Three phase connection ...........................................................................................11

8Display and Menu Structure................................................................................11

9Taking the Tester into Operation........................................................................11

9.1 Visual check .............................................................................................................11

9.2 Connecting the tester to the mains system ...............................................................11

9.3 Starting the test.........................................................................................................11