M2050 Recovery System

User Instruction Manual

INSTRUCTION # IM-0017 REVB

ISSUE DATE 10/28/10

EXPIRATION DATE 10/28/20

4451 Raceway Dr • Concord, NC 28027 • Customer Service Phone (800) 560-1094 • Fax (800) 560-1275

Page 4 of 7

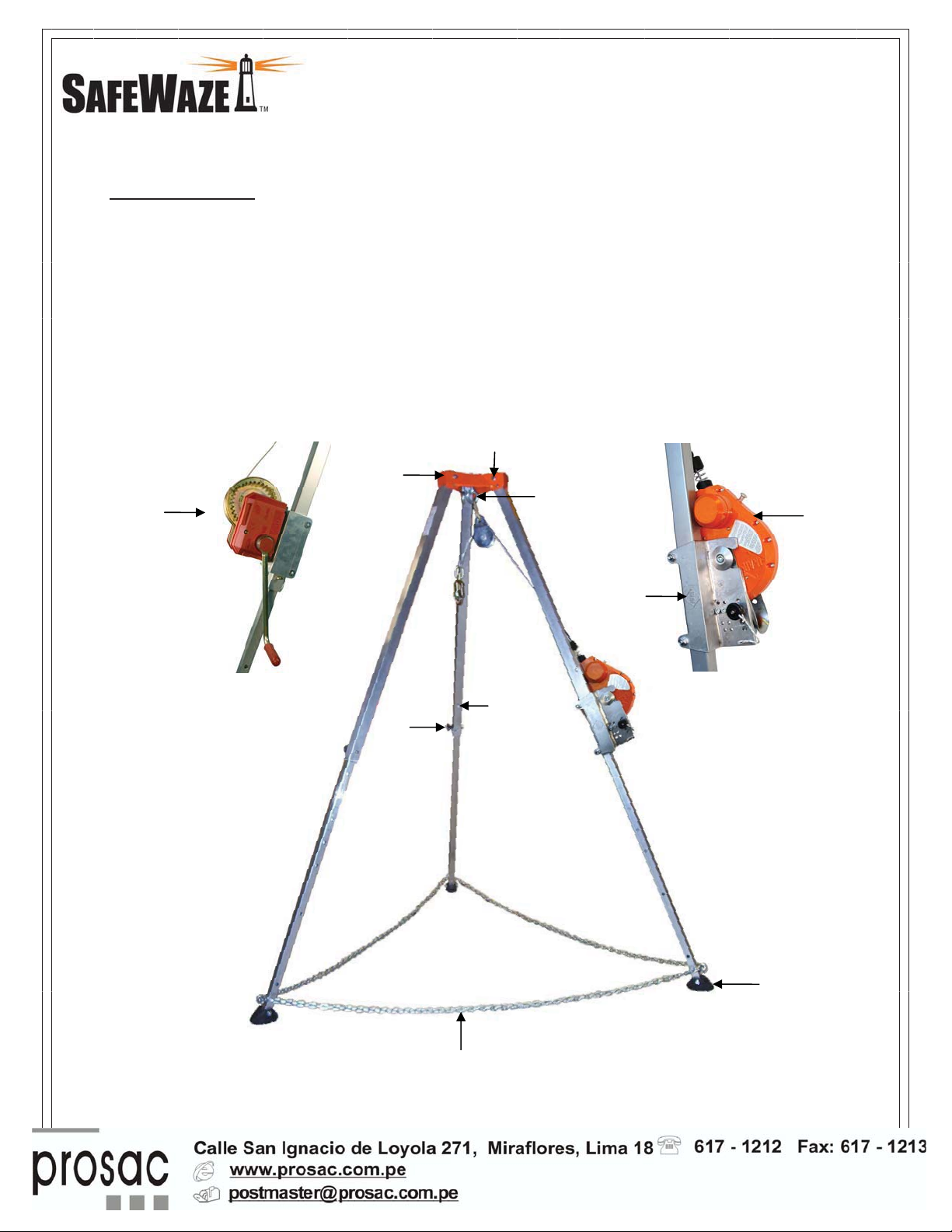

M10 Installation Instructions

All individuals who may use, or be required to use, the M10 Tripod must be instructed on how to use it correctly. They must read, understand,

and follow all instructions and warnings stated on, contained in, or attached to the Tripod. A review of the proper procedure should be made

before each use.

M10 Assembly

Before using, make sure that the type of Tripod meets the application requirements as described in the technical specification, that is:

x The center of the opening corresponds to the center of the Tripod.

x The diameter of the opening is within the range specified in the technical specification.

x The interior height of the Tripod is chosen correctly.

Before assembling, inspect the vicinity around the work area for debris and other material that could cause injuries or interfere with the

operation of the system. Be sure that the Tripod is positioned on a hard, stable surface before use, and that the chain (6) is in place and

secured. In addition, before descent, caution should be taken to ensure that all equipment is clear of any electrical hazard and that proper

ventilation has been provided in the work area. There is more than one way to assemble the Tripod. Outlined below is the recommended

procedure for assembly.

1. Lay the contracted Tripod on the floor at a safe distance from the opening.

2. Extend all three legs to full length, being sure latch (10) is engaged to latch the leg in extended position and then

secure each with the attached lock pin (4).

3. Lift the Tripod to the vertical position and pull all three legs away from the Tripod center point, making sure that the

lock (3) where each leg is hinged to the head (1) is fully engaged.

4. Check to make sure that:

x All extended legs are secured with lock pins (4) and are latched. Look for latch button (10) in hole in inside of

leg to be present.

x Each leg is set at the furthest point from the center and locked by the hinge lock (3).

x The chain (6) is in place and adjusted to the right length.

5. Place the Tripod over the confined space opening after loading with equipment.

6. Make sure that the Tripod is in a stable position with each foot (6) flat on the floor.

7. The Tripod is now ready for installation of SafeWaze® Fall Protection equipment.

M10 Tripod Disassembly

1. Remove all SafeWaze® Fall Protection equipment from the Tripod.

2. Remove the Tripod from the confined space opening.

3. Unlock leg hinges (3) in the Tripod head (1) and release leg latch button (10). Gradually push each leg to the Tripod

center point and embrace all three legs. Lower the Tripod to the ground.

4. Pull the leg lock pins (4), release the leg latch button (10), and push the lower leg sections into the upper leg sections.

5. Lock the contracted legs in the storing position with the lock pins.

Part Numbers for Ordering

M2050 M10 Tripod, 205G-50 3-Way Recovery System

M2075 M10 Tripod, 205G-75 3-Way Recovery System

142G 65' Winch

M10-142G M10 Tripod, 142G Winch

M10 7' Tripod

205G-50 50' 3-Way Unit

205G-75 75' 3-Way Unit

205G-100 100' 3-Way Unit