(2)Next,intheconditionof(1),fullyopenthethrottlevalve,turnbackthemainneedletomaketheair-fuelmixtureveryrichin

therangewheretheenginedoesnotstall(about4,000rpm).Operateinthisconditionwith2(ormore)tanks.(Conductthis

stepcheckingthedensityoftheexhaustandthebreatherʼswasteoil(inky-blackwasteoil)).

(3)Next,afterfillingupthetank,re-starttheengine.Withthethrottlevalvefullyopened,throttlethemainneedleandoperate

theengineforonetankat7500‒8,000rpm.

(4)Next,afterfillingupthetank,re-starttheengine.Withthethrottlevalvefullyopened,turnthemainneedlefromtherichto

thepeaksseveraltimes.Whenthepeakbecomestable,openthethrottlevalvefromlowspeedtohighspeedseveraltimes

tochecktheresponse.Andgraduallyelongatethetimeofhigh-speedoperation.Conductthisoperationforonetank.

(5)Whentherevolutionisstabilizedatpeak,theground-levelbreak-iniscompleted.Afteradjustingthetappetgapinthe

mannerofsection“14”,adjustthecarburetoraccordingtothefollowingsection.Therunning-iniscompletedbyperforming

some20flightsinalittlerichcondition.Subsequently,theflightshouldbeperformedinsucharichconditionasfarasnotto

influencetheflight.

13.Adjustmentofcarburetor

Theprincipalmethodofadjustmentisthesameasthatforourglowengine.

Inprinciple,acarburetorisadjustedbyfirstachievingpeak(thehighestrevolution)withthemainneedleandthensetidling

(lowspeedrevolution)withthethrottlevalveandtheslowneedle.(Unlessthepeakiscertainlyachieved,idlingadjustmentwill

bedifficultandnotstabilized.)

(1)Afterfillingupthefueltank,starttheengineinthemannerofSection“11”andthenfullyopenthethrottlevalvewiththe

throttlestick.

(2)Byturningthemainneedledependingonthetachometerandtheexhaustsound,achievepeakcarefully.

*Asforadjustingthemainneedleinthecaseofactualflight,settingthepeakintheperpendicularattitudewithapropeller

intheupwarddirectionisrecommendedifitʼspossible.Inthatadjusting,itʼllberichenoughinthehorizontalattitudeso

itʼsmoresimilartotheconditionduringtheactualflight.

(3)Next,closethethrottlevalveuntiltheengineoperatesstablywithanidlingrotationofaround2000-2500rpm,adjusting

theslowneedlewiththe(-)screwdriverandthethrottlevalvecarefully.

*Sincetherichnessleveloftheair-fuelmixturevariescorrespondingtothenatureoftheairframe,pleaseadjustitdepending

ontheuserʼsskill.

Generally,inascaleflightinwhichthestabilityofalow-speedzoneisconsideredasimportantandtheengineisoperated

slowly,adjusttheair-fuelmixturetoberelativelylean.Inanacrobaticflightinwhichtheearlystand-upfromalowspeedis

consideredasimportant,adjusttheair-fuelmixturetobeslightlyrich.

(4)Aftertheidlingisset,getthethrottlevalveslowlyfullyopened.Iftherevolutionbecomessloworgoesupsuddenly,adjust

carefullyuntilitchangeslinearlyfromidlingtopeak,byfine-tuningwiththeslowneedle.

(5)Aftertheaboveadjustmentiscompleted,openthethrottlevalvefromidlingtopeakquickly.Iftherevolutiondoesnot

achievepeakimmediatelybutgetdelayedasthethrottlevalveisfullyopened,fine-tunethemainneedleandperformthe

sameprocessfromidlingtopeakquickly.Repeatthiscarefullyuntiltheresponseimproves.

*Thekeytomaketheenginelastforlonglifeisoperatingwiththeslightlyrichconditionasfarasitdoesnʼteffecttotheflight.

Adjustmentisneededdependingontheengineattachmentdirection,thepropeller,thefuel,theplug,theclimatecondition,

etc.Duringflights,pleasefine-tunesothatlowspeed,mediumspeed,andhighspeedmatchbestwiththeairframe.

14.Normaloperation,maintenance,andadditionalinformation

(1)Justafterstartuptheengine,performwarmuprunninginrichconditionforabout1minute,andjustbeforestoprunitat

idlingfor1minutetocooldownaswell.

(2)Whenstoptheengineafterthefinalflightoftheday,besuretostopbycuttingthefueltoremovefuelfromthecarburetor.

Andremovethefuelfromthetankandreserveitwithspecialcare.

(3)Sincethefuelcontainsmorethan5%ofoil,sometimestheexhaustvalvegetsdullbycarbonorsludgeespeciallyincold

atmosphere.Thenturnofftheignitionswitchandrotatethepropbyelectricstarter.Afterdilutetheoilcontentbythisway,

removethefuelfrominsidethecarbandtheengine.Ithelpsthevalvetomovesmoothly.

Or,removetherockercoverandapplyingsomeanti-rustspraytotheexhaustvalveiseffectiveaswell.

(4)Lubricationforpiston,connectingrod,bearingorcamgearisablow-bylubricationinwhichtheoilinthefuelgoesintothe

crankcasefromtheclearancebetweenthecylinderandpiston.Thereforetheenginelifeisaffectedbythepropertyofthe

fueloil.Pleaseusehighqualityoil.

(5)ChargethebatteryfortheignitionsystemandRCdevicefully.(Sincetheignitionsystemgenerateshightension,becareful

ofelectricalshock.)

(6)Sinceoverclosingthemainneedlecausesoverheating,adjustalittlemorerichthanpeak.Overclosingleadstoknockingor

overheatandhasanadverseeffectontheconnectingrodandcamgear.Wheretheairplaneachievespeakcompletelyat

thetimeofascentshouldbeaproperpeakoftheengineduringflight.

(7)Whenconnectingtheexhaustpipetothecylinderorattachingthepropnut,applythincoatofsiliconrubber(notexces-

sively)oradhesiveonthethreadsectionbeforetightening.Thispreventsleakageorloosening.

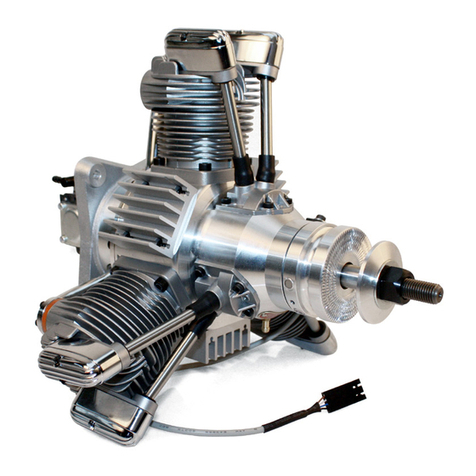

(8)BecauseallofSAITOgas-enginesuseoil-fuelmixture,theretendtobecarbonbuildupinside

themufflerasshowninthepicture.Itcausessomeproblemsontheexhaustoutletand

consequentlyreducesthepower.Thereforecleaning/removingcarboneveryabout50flights

isrecommended.Usingapartscleaningsprayiseffectiveway.Actually,itdependsonthe

qualityoftheoilsowhenyoufeelthepowerloss,pleasecheckinsidethemuffler.

Inthecaseofthepicturewhichhadbeendonemorethan70flights,byremovingthecarbon

buildup,thesmoothnessoftheengineimproveddramatically.

-5-

Note:Duringearlystageofflights,taketheheighthighenoughtolandsafelyincasetheenginestopintheairsuddenly.It

willreducetheriskofcrashorlandingaccident.

Caution:Overclosingthemainneedleisverydangerousbecauseitmaycauseknockingandpropellernutloosening.Then,

turnthemainneedleCCWimmediatelytomakeitrichalittle.