●Unlessthepeakiscertainlyachieved,idleadjustmentwillbedifficultandnotstabilized.

●Startuptheengineandrunfor1minuteinrichcondition.Thenfullyopenthethrottle.

●ByturningthemainneedleCW,observingtachometerandexhaustsound,achievepeakcarefully.

●Operatethethrottletolowuntiltheenginerunsstablywithanidlespeedaround1,500rpmbyadjustingtheslow

needlewitha⊖screwdrivercarefully.

●Onceidlespeedisset,openthethrottletofullgradually.Ifthespeedbecomessloworgoesupsuddenly,adjustthe

slowneedlecarefullyuntilthespeedriseslinearlyfromidlingtopeakbyfine-tuning.

●Afterthatperformtheprocessfromidlingtopeakquickly.Ifthespeedrisesnon-linearly,finetunethemainneedle.

●Ifthespeedaroundslow-midrangegetscoughorhesitating,finetunetheslowneedleandchecktheresponseas

well.Repeatthisfine-tuningandresponsecheckcarefullyuntiltheresponseimproves.

●Carbadjustmentisaffectedbymanyfactorssuchasprop,flightstyle,humidity,temperature,atmosphere,oil,plug,

fuel,andsoon.Pleasekeeptryingtofindthebestconditiontomatchyourplane.

●Thebestrichnessoftheair-fuelmixtureatslowspeeddependsontheflightstyle.Generally,Scaleflightrequires

stabilityinlowspeedsoslightlyleanconditionispreferable.Acrobaticflightrequiresquickresponsefromlowthrough

high,soslightlyrichconditionispreferable.

●Tipforadjustmentoftheslowneedleistomakeitasleanastheenginedoesnʼtgetstolewhenopenthethrottlequickly.

●Tokeeptheenginelifelonger,adjustthemainneedleasrichaspossibleintherangeitdoesnʼtaffecttotherunning.

●Sinceoverthrottlingofthemainneedleleadstoknockingoroverheatandhasanadverseeffectontheconnecting

rodandcamgear,adjustalittlericherthanpeak.

●Onceyounoticeabnormalvibrationorsoundduringthrottlingthemainneedle,justreturntoopentheneedle

immediately.

●Wheretheplaneachievespeakcompletelyattheattitudeofascentshouldbeaproperpeakoftheengineduring

flight.

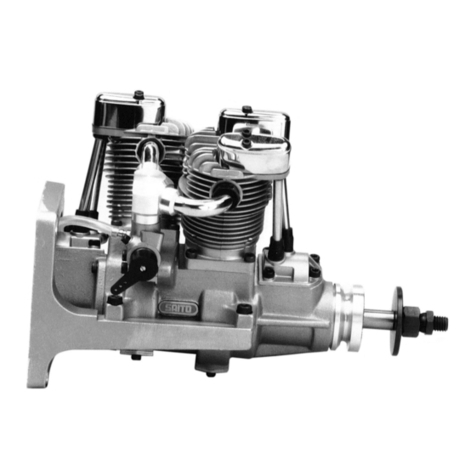

10.Tappetadjustment

●Aftercompletinggroundbreak-inoroperatingtheenginefor1hour,adjust

tappetgaps(valveclearances)byfollowingproceduretocompensateinitial

wearing,whiletheengineiscold.

●#1cylindershouldbeadjustedfirst,next#3,finally#2cylindershouldfollow

inorderbythesameprocedure.

●Removethesparkplugandrockercoversfromthe#1cylinder.

●Iftheattachedgauge(limitgauge,t=0.1mm)comestobeinserted,gaphas

beenenlargedbeyondtheallowablelimit.

●Turnthepropslowlyforwardbyhanduntiltherockerarmofintakestops.Furtherturntheproptobringthepistonto

theTDC(TopDeadCenter)ofcompressionstroke.

●Usetheattachedwrenchandhexagonalwrenchtoadjustthegapsindefinitelyclosetozero.

●Afteradjustment,putonthesparkplugandturnthepropforwardtocheckifthecompressionisenough.

●Ifthegapislowerthan0,thevalveisopenedallthetimesothecompressionisnotgenerated(then,loosenthescrew

toreset).

●Ifthegapiscorrectandcompressionisenough,securelytighten(butnotexcessively)thelocknut.

●Dothesameadjustmentforthe#3-#2cylindersinorder.

●ForSAITOengines,thetappetgapisenlargedduringoperationduetothermalexpansionofthecylinder(madeof

aluminum).Thereforesetthegapindefinitelyclosetozerowhentheengineiscold.

●Astappetgapisoneofthemostimportantfactorsinthemaintenanceof4-strokeengines,occasionallycheckit.

11.Other

●Duringoperation,thescrewsallovertheenginecanbeloosenbyheatexpansionofmetal.Sopleasetightenupthem

occasionally.

●Justafterstartuptheengine,performwarmuprunninginrichconditionforabout1minute,andjustbeforestoprun

itatidlingfor1minutetocooldownaswell.

●Whenstoptheengineafterthefinalflightoftheday,besuretostopbycuttingfueltoremovefuelfromthecarbure-

tor.Andremovethefuelfromthetankandreserveitwithspecialcare.

●Whentheexhaustvalvegetsdullbycarbonorsludgeespeciallyincoldatmosphere,removetherockercoverand

applysomeanti-rustspraytotheexhaustvalvetohelpthevalvetomovesmoothly.

●Neveruseanti-rustspraythatcontainsorganicsolventwhichdegradesrubbersealsinsidetheengine.

●Sometimestheoiloozesfromeachjointorcommissurehoweveritʼsnoproblemonperformance.

●Notesforpurchasingparts:Pleasegiveorderstotheshopyoupurchasedfromwith“Enginemodel”,“PartNo.orpart

name”,and“Quantity”.

Optionalparts

・Filterwithweight[G36-154] ・Rubbertubeforgasoline(1m)[G36-155]

・SparkplugSP-2[G60R3-120] ・Aluminumspinnernut[57T-30]

・Tappetadjustingkit[30-161] ・Digitaltachometer[G17-167]

Tappetadjustment

Fig.10

Mustnotbeinserted

(overgap)

Limitgauge

(0.1mm)

Closeto"0"withnolimit

-5-