BF-Sirius

Manual

Machine Installation1 .................................................III-2

ToolsRequiredintheInstallationProcess1.1 ................................III-2

UnpackingandInstallingtheMachine1.2 .......................................III-2

ItemstobeVerifiedatUnpacking1.2.1 .....................................III-2

InstallationCondition1.2.2 .........................................................III-3

RemovetheFixingPlate1.2.3 ...................................................III-3

DevicesConnection1.2.4 ..........................................................III-4

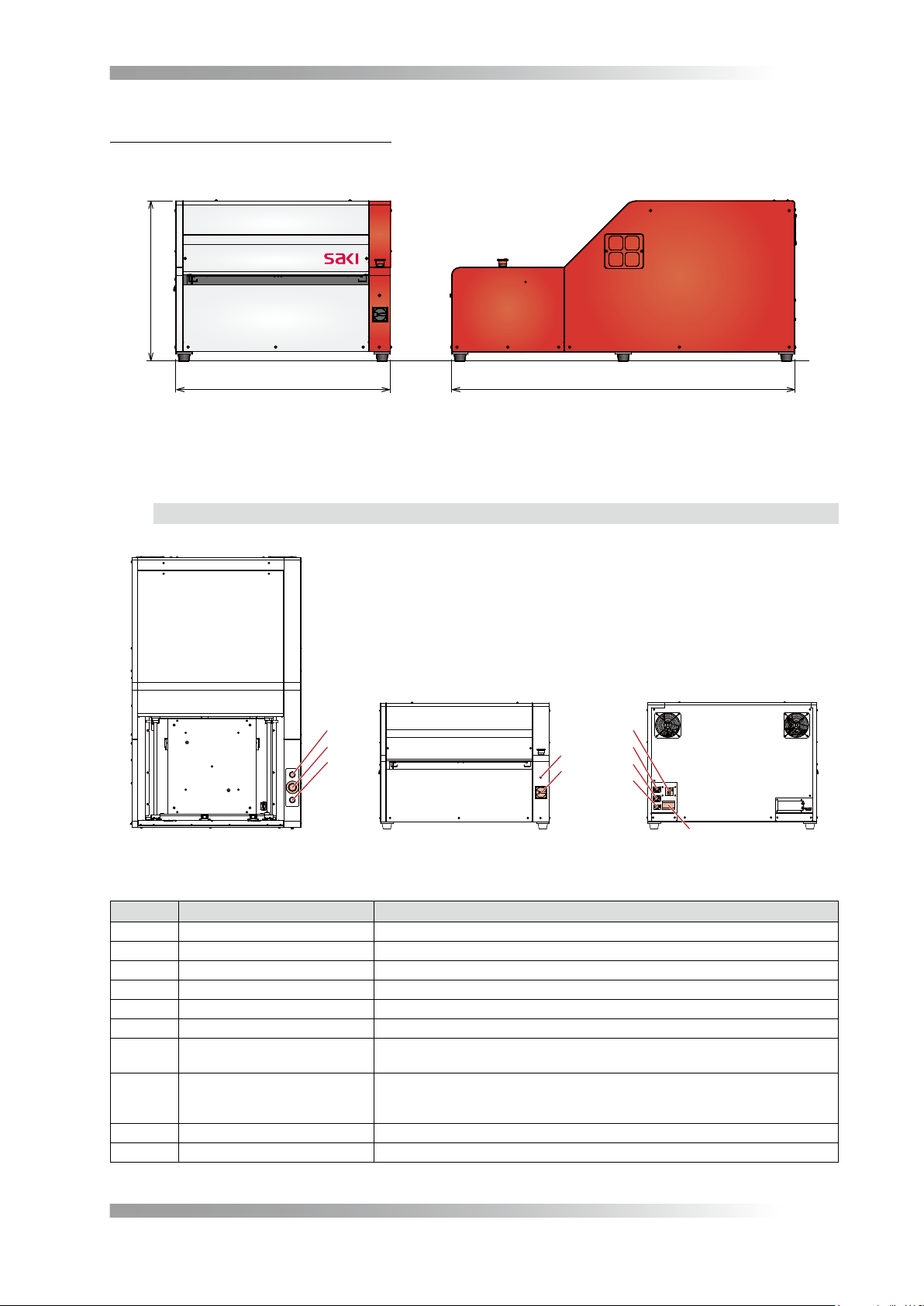

Product Specications1 .............................................IV-2

Maintenance and Service2 .........................................IV-4

MaintenanceandService2.1 ......................................................... IV-4

AfterSalesService2.1.1 .......................................................... IV-4

ProductWarranty2.1.2 ............................................................. IV-4

MaintenanceCheckService2.1.3 ............................................ IV-5

Others2.1.4 .............................................................................. IV-5

CustomerSupportContacts2.2 .................................................... IV-5

Information on Terms of Use3 ...................................IV-6

EC Declaration of Conformity4 ...................................IV-8

Installation

TableofContents

Specication/

CustomerSupport

TableofContents

Maintenance1 ..............................................................II-2

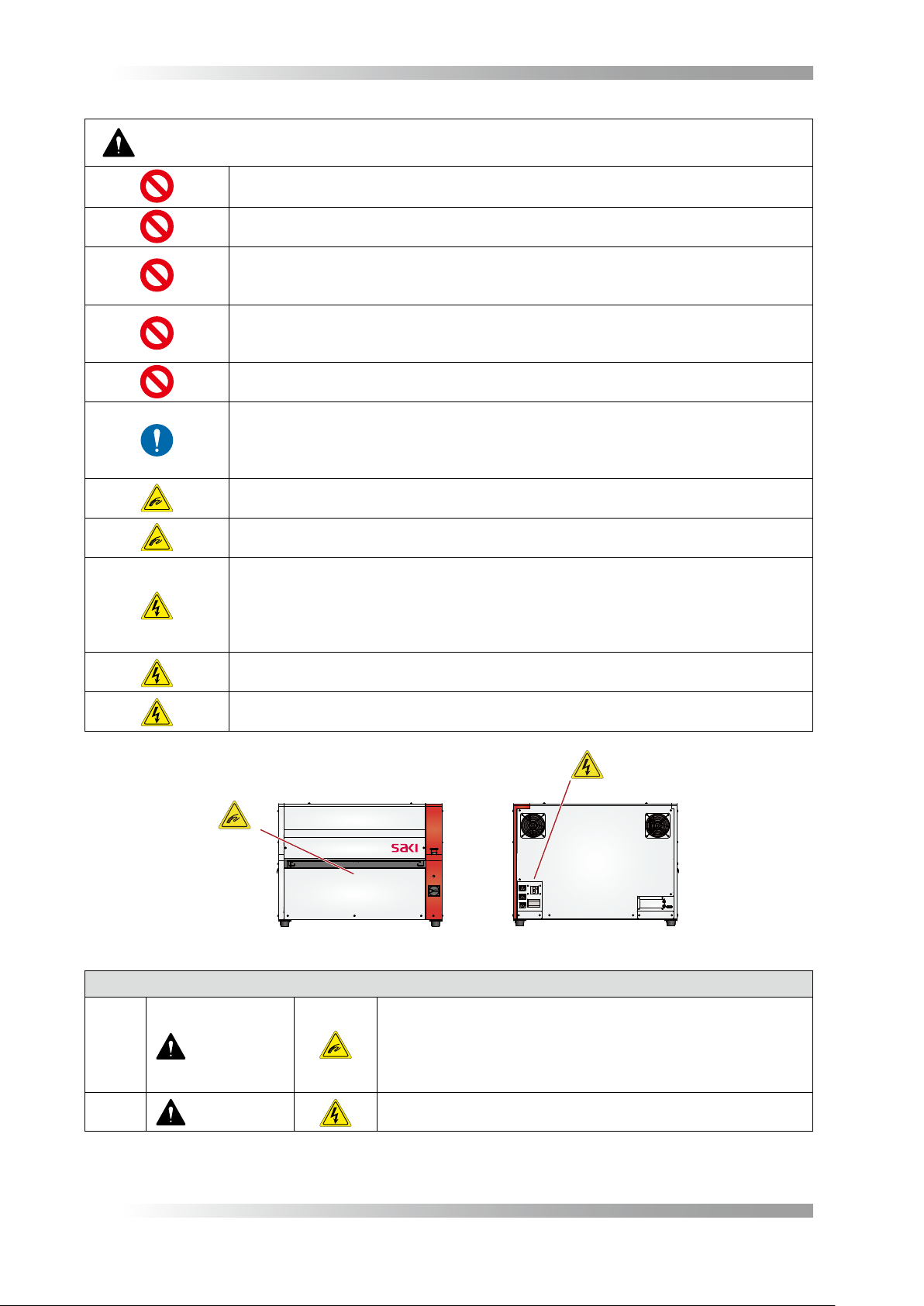

MaintenancePrecautions1.1 ...........................................................II-2

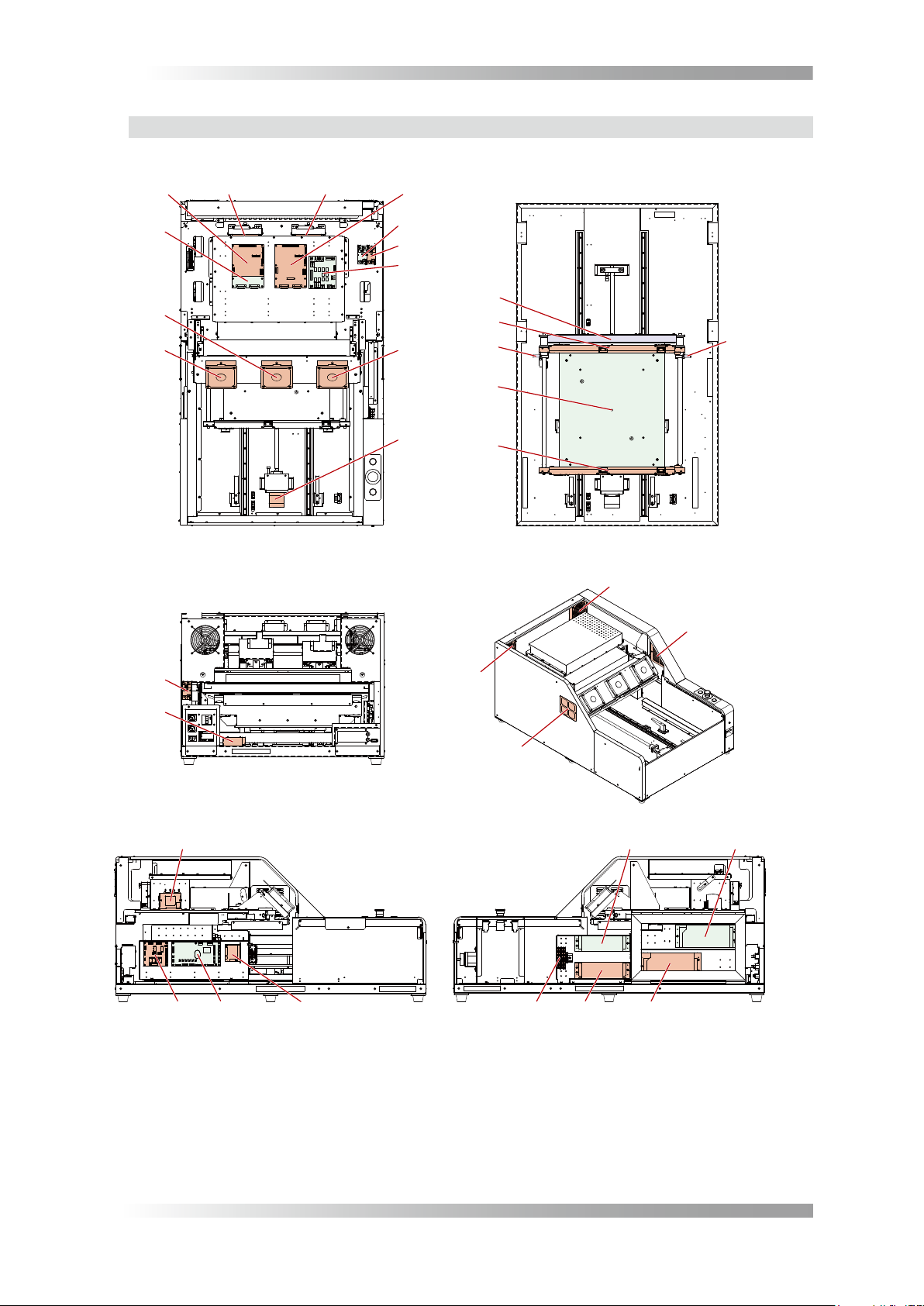

HowtoRemoveExternalCover1.2 .................................................II-2

CleaningOpticalSystem1.3 ............................................................II-3

PreparationsforOpticalPartsCleaning1.3.1 .............................II-4

CleaningShadingSheet1.3.2 ....................................................II-5

CleaningDiffuser1.3.3 ...............................................................II-5

CleaningLightControlFilm1.3.4 ................................................II-7

CleaningTelecentricLens,Mirror,andCameraLens1.3.5 .......II-8

Greasing-up1.4 ..............................................................................II-11

Adjustment, Replacement, and setting of Main Parts2

..II-13

SensorAdjustment2.1 ...................................................................II-13

TypeA:DogSensor2.1.1 .........................................................II-13

TypeB:ReflectiveBoardSensor2.1.2 .....................................II-13

TypeC:FiberopticSensorAmplifier2.1.3 ................................II-14

MaintenanceParts2.2 ...................................................................II-14

ReplacementofLEDLighting2.2.1 ..........................................II-15

BoardSettingsandMotorDriverSettings2.3 ................................II-16

ImageProcessingBoard2.3.1 ..................................................II-16

OptionSignalBoard2.3.2 .........................................................II-16

ScanMotorDriver2.3.3 ............................................................II-17

ElectricalConnectionDiagram2.4 .................................................II-18

SafetyCircuitDiagram2.5 .............................................................II-20

Backup3 .....................................................................II-21

BackingupinE:Drive3.1 ..............................................................II-21

BackingupinC:Drive3.2 ..............................................................II-21

ExternalBackup3.3 .......................................................................II-21

Troubleshooting4 .......................................................II-22

FailuretoOperateNormally4.1 .....................................................II-22

Error/WarningMessage4.2 .........................................................II-24

Maintenance

TableofContents