6

6. NOTES:

How it Works

Infrared thermometers measure the surface temperature of an object. The unit’s optics sense emitted, reflected, and

transmitted energy, which is collected and focused onto a detector. The unit’s electronics translate the information into a

temperature reading, which is display on the unit. In units with a laser, the laser is used for aiming purposes only.

Field of View

Make sure that the target is larger than the unit’s spot size. The smaller the target, the closer you should be to it. When

accuracy is critical, make sure the target is at least twice as large as the spot size.

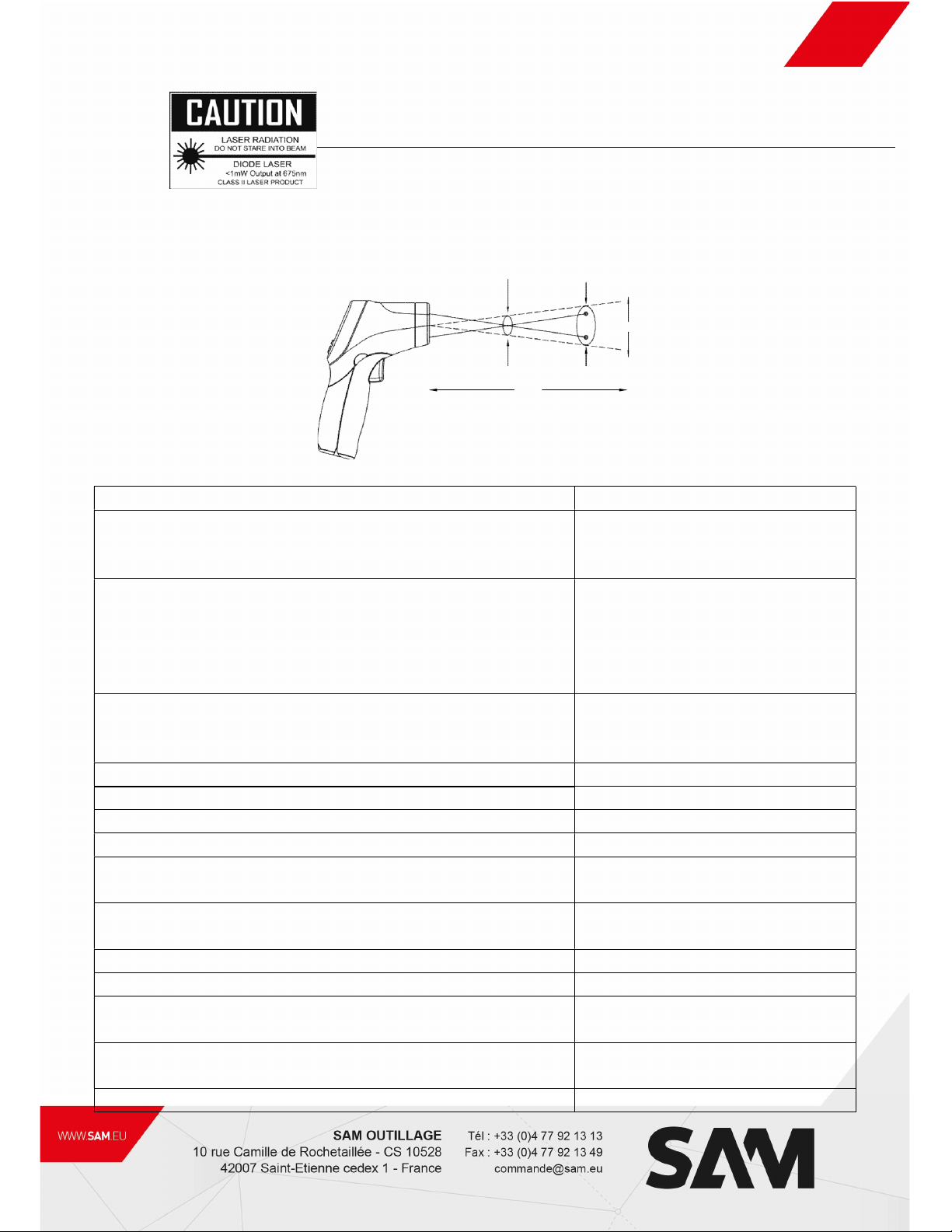

Distance & Spot Size

As the distance (D) from the object increases, the spot size (S) of the area measured by the unit becomes larger.

See: Fig: 1.

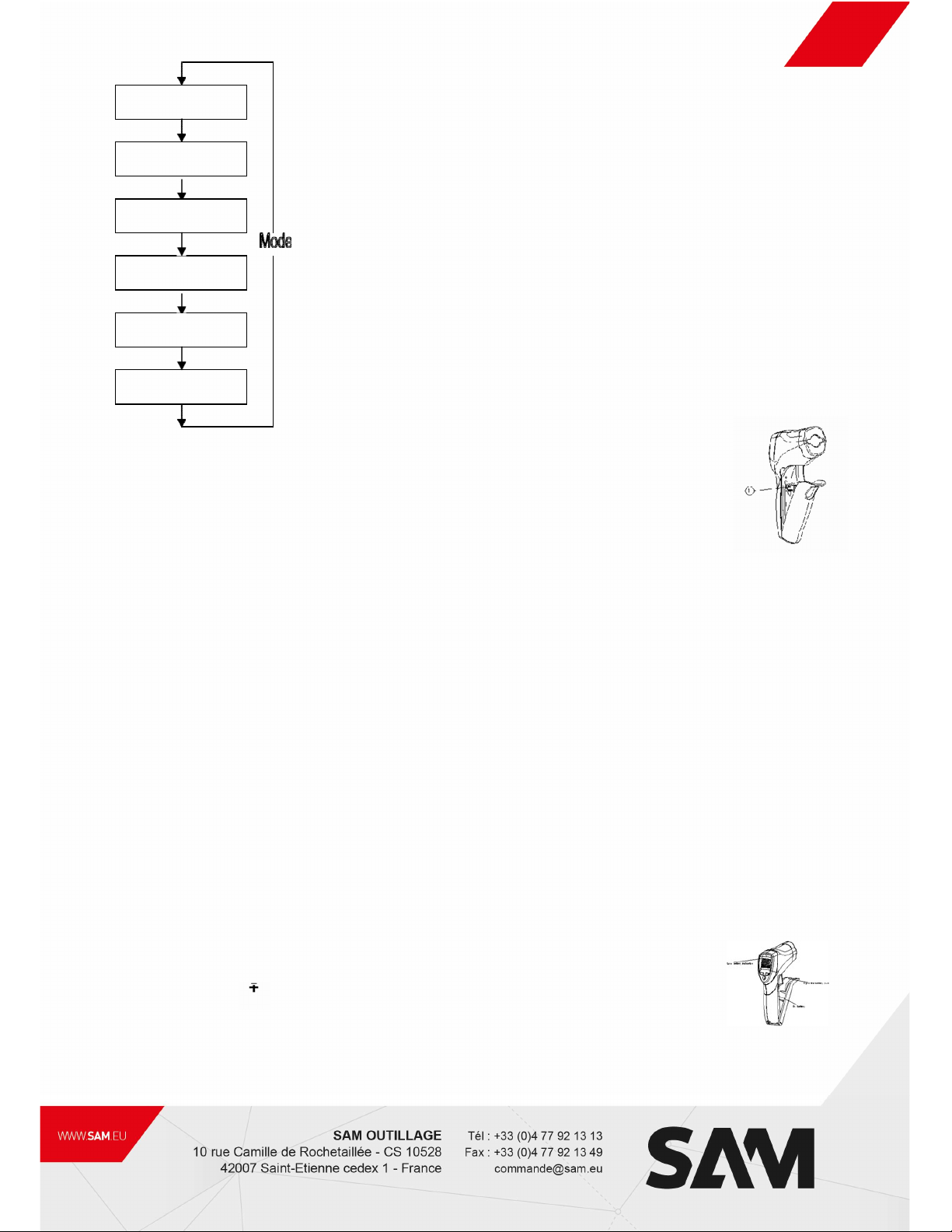

Locating a hot Spot

To find a hot spot aim the thermometer outside the area of interest, then scan across with an up and down motion until you

locate hot spot.

Reminders

① Not recommended for use in measuring shiny or polished metal surfaces ( stainless steel, aluminum, etc.).See

Emissivity

② The unit cannot measure through transparent surfaces such as glass. It will measure the surface temperature of the

glass instead.

③ Steam, dust, smoke, etc., Can prevent accurate measurement by obstructing the unit’s optics.

Emissivity

Emissivity is a term used to describe the energy-emitting characteristics of materials.

Most (90% of typical applications) organic materials and painted or oxidized surfaces have an emissivity of 0.95 (pre-set in

the unit). Inaccurate readings will result from measuring shiny or polished metal surfaces. To compensate, cove the surface

to be measured with masking tape or flat black paint. Allow time for the tape to reach the same temperature as the material

underneath it. Measure the temperature of the tape or painted surface.

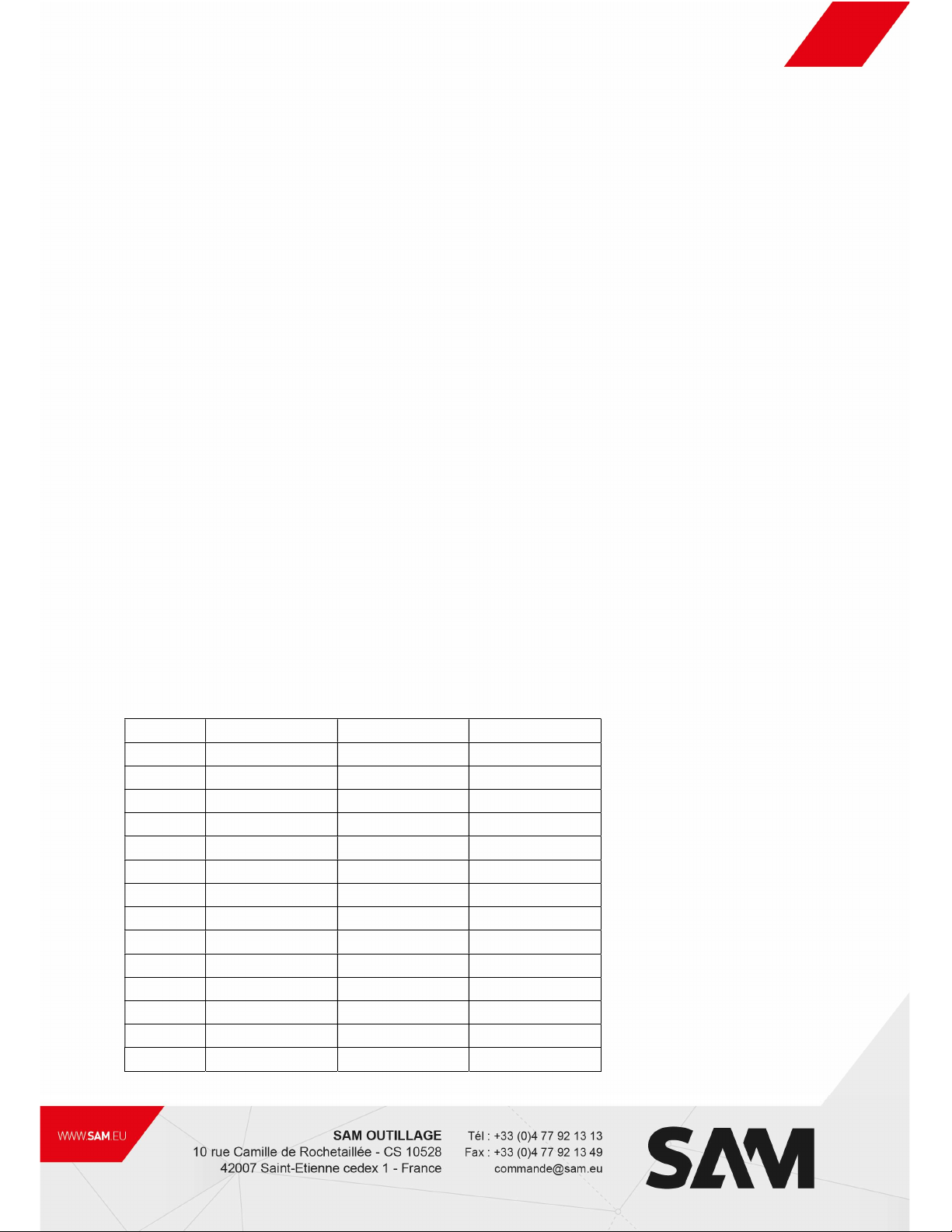

Emissivity Values

Substance Thermal emissivity Substance Thermal emissivity

Asphalt 0.90 to 0.98 Cloth (black) 0.98

Concrete 0.94 Human skin 0.98

Cement 0.96 Lather 0.75 to 0.80

Sand 0.90 Charcoal (powder) 0.96

Earth 0.92 to 0.96 Lacquer 0.80 to 0.95

Water 0.92 to 0.96 Lacquer (matt) 0.97

Ice 0.96 to 0.98 Rubber (black) 0.94

Snow 0.83 Plastic 0.85 to 0.95

Glass 0.90 to 0.95 Timber 0.90

Ceramic 0.90 to 0.94 Paper 0.70 to 0.94

Marble 0.94 Chromium oxides 0.81

Plaster 0.80 to 0.90 Copper oxides 0.78

Mortar 0.89 to 0.91 Iron oxides 0.78 to 0.82

Brick 0.93 to 0.96 Textiles 0.90