Doc.-ID: 181210-PT10BA-ES-RoughCam IPM3016_en_rev.00.docx, page 7 of 24

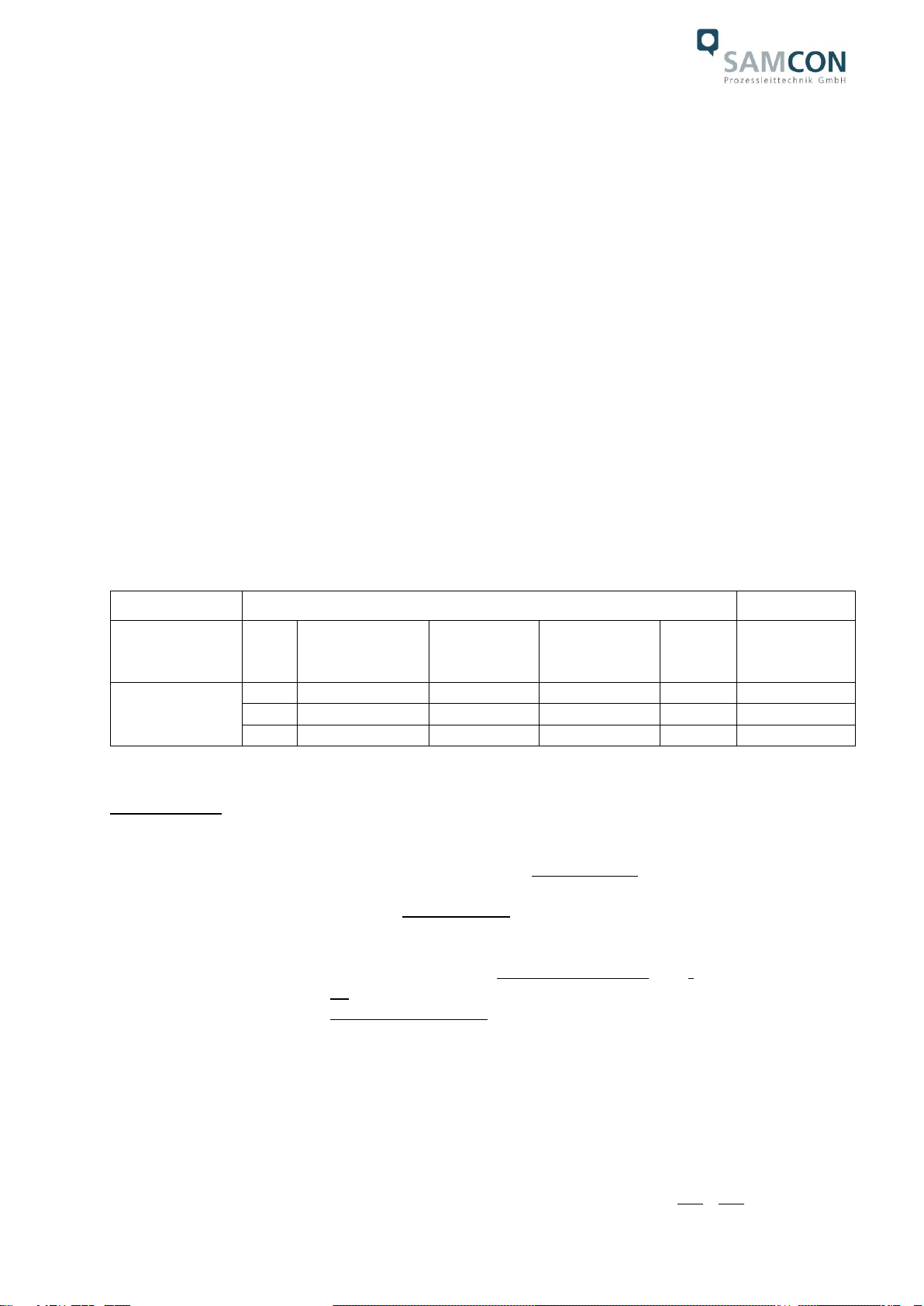

2.5 Other technical data

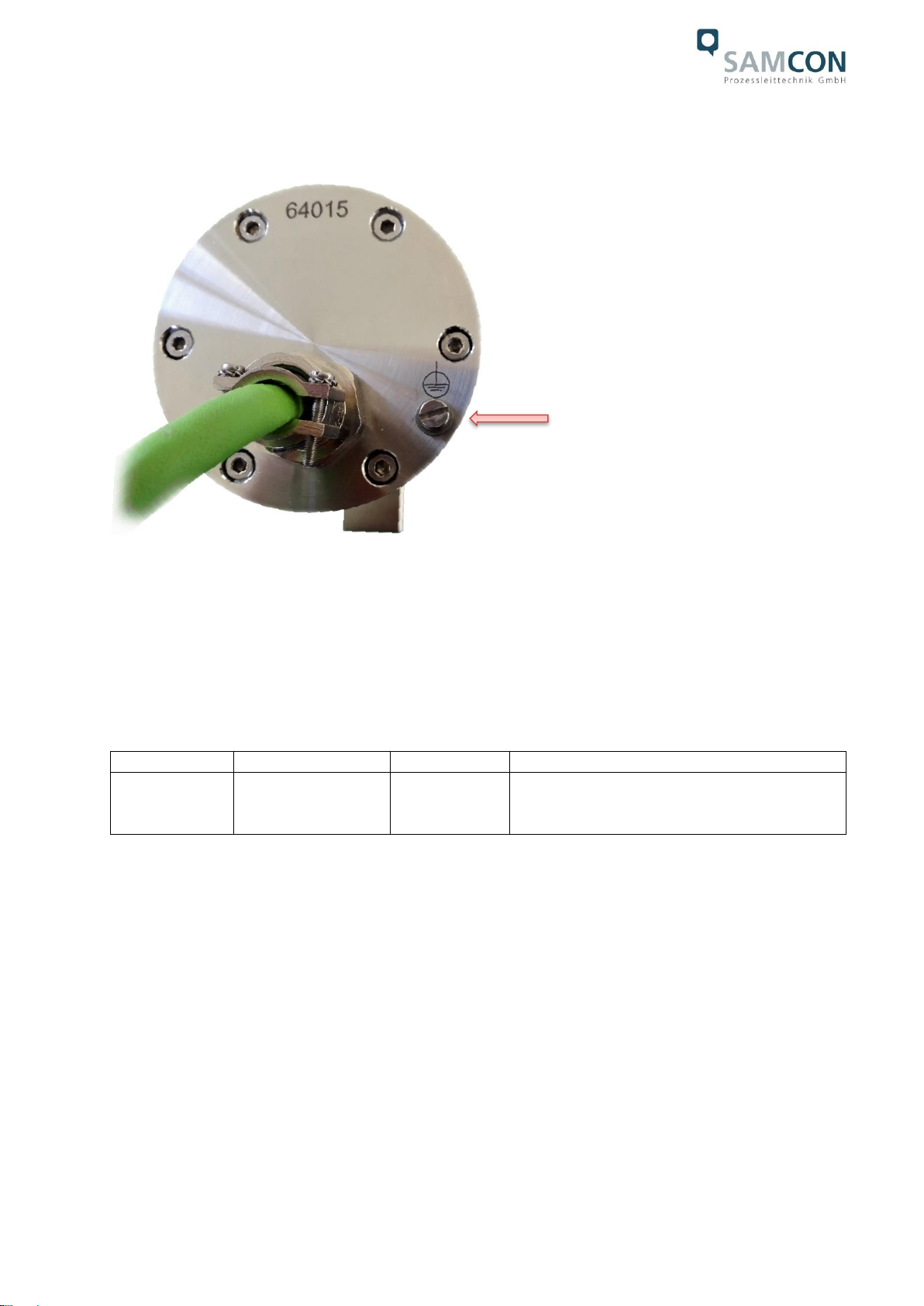

Protection level: IP 68 (IEC/ EN 60529)

Transportation / storage temperature: 5°C … +55°C

Ambient temperature: -60°C … +55°C (Type:…LL.N…)

-5°C … +55°C (Type:…N.N…)

Housing material of the enclosure according to DIN EN 10027-2: 2015-07 (designation

system for steel):

Housing material (standard)MNo.: 1.4404 (X2CrNiMo17-12-2),

AISI 316L / V4A

Additional metallic and non-metallic materials of the T11 VA1.2.x.x

housing: Zinced spring steel MNo.: 1.0330, PTFE with

glass microbeads (GYLON Style 3504 blue),

silicone-coating (Silcoset 105 incl. CureAgent

28), VMQ (silicone), thermos transfer foil made

of polyester (acetone resistant), cable glands

made of brass, nickel-plated (MsNi)

Sight glass material: Borosilicate glass “Ilmadur 10/ I-420”

Internal materials: Optical and electronical components, div. ther-

moplastic plastics: polyamide (PA6.6/ PA2000)

and polyoxymethylene (POM) isolators and

supporting adapters, Aluminum die cast, zinced

(aluminum universal adapter (EN AW-

ALSi1MgMn), PTC-ceramics, PUR, etc.

Weight (without accessories): 3,000 g

Weight of accessories: 800 g (wall mount bracket WMB-S)

400 g (hood WPR-VA1.2)

50 g (hinge attachment SCH-VA1.x)

(further accessories upon request)

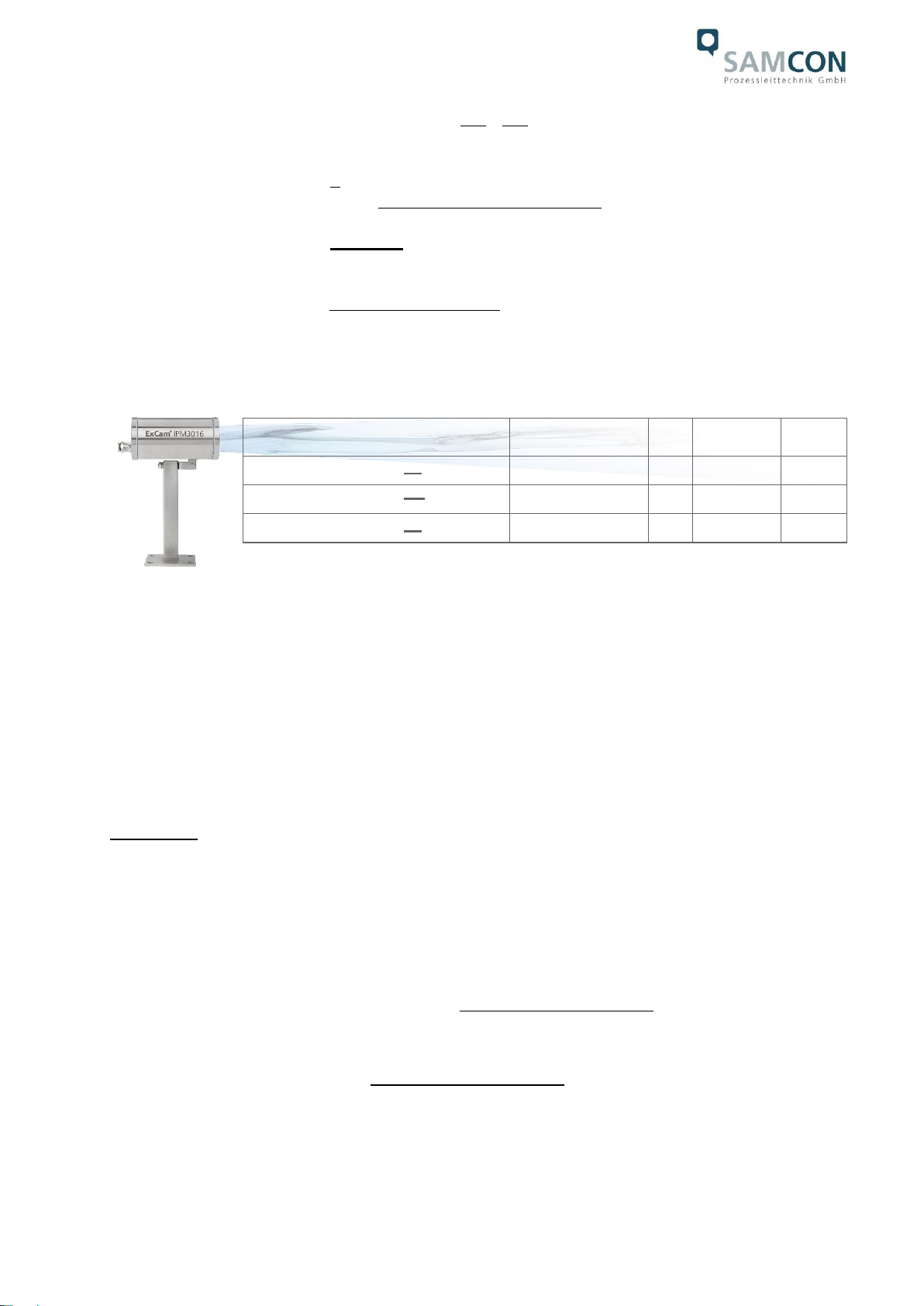

Dimensions housing (wxhxd): 79.0mm x 96.0mm x 158.0mm

Dimensions with accessories (WxHxD): 97.0mm x 193.0mm x 299.5mm

(with wall mount bracket and hood)

Media resistance: Exclusively checked upon request!

Generally: corrosion resistant, as well as chemi-

cal highly resistant against a variety of fluid and

gaseous components of the industriel area and