Contents

EB 5757 EN 3

1 Safety instructions and measures ...................................................................5

1.1 Notes on possible severe personal injury .........................................................8

1.2 Notes on possible property damage................................................................9

2 Markings on the device ...............................................................................10

2.1 Actuator nameplate......................................................................................10

2.2 Valve nameplate ..........................................................................................10

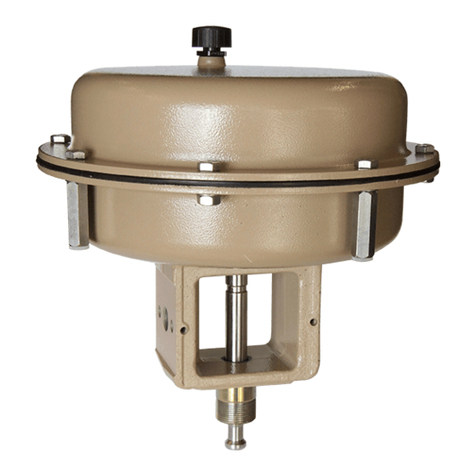

3 Design and principle of operation ................................................................11

3.1 Operating controls .......................................................................................12

3.1.1 LEDs ...........................................................................................................12

3.1.2 Handwheel..................................................................................................14

3.1.3 Travel indicator............................................................................................14

3.2 Accessories .................................................................................................14

3.3 Technical data .............................................................................................15

3.4 Dimensions in mm........................................................................................16

4 Preparation.................................................................................................18

4.1 Unpacking ..................................................................................................18

4.2 Transporting and lifting ................................................................................18

4.2.1 Transporting ................................................................................................18

4.2.2 Lifting..........................................................................................................18

4.3 Storage.......................................................................................................18

5 Mounting and start-up.................................................................................19

5.1 Mounting the actuator onto the valve.............................................................19

5.2 Installing the control valve into the pipeline ....................................................19

5.3 Electrical connections ...................................................................................19

5.4 Conguringtheelectricactuator....................................................................20

6 Operation...................................................................................................20

6.1 Manually changing the stem position.............................................................20

7 Servicing.....................................................................................................24

7.1 Preparation for return shipment.....................................................................24

8 Malfunctions ...............................................................................................24

8.1 Emergency action ........................................................................................24