6 KH 8390-5 EN

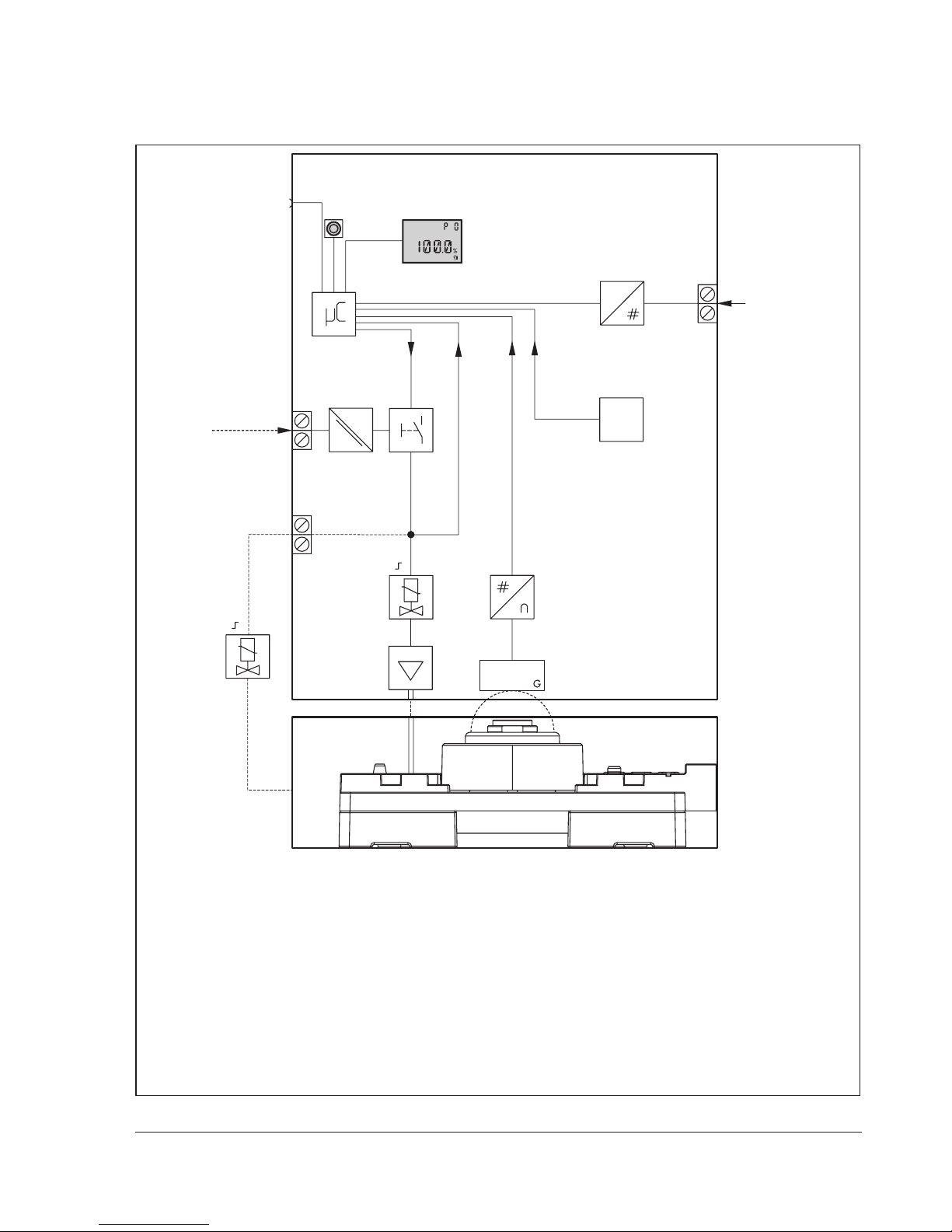

Principle of operation

2 Principle of operation

The electronic limit switch is designed for attachment to pneumatic actuators. The current

valvepositionismeasuredwithoutcontactusingamagnet(onascrew)positionedcentrically

ontheactuatorshaft.Thescrewwithmagnetdoesnotneedtobeadjusted.TheAMR(aniso-

tropicmagnetoresistive)sensorlocatedinthedevicetogetherwiththemeasuringelectronics

(1)candetectthedirectionalchangeoftheappliedmagneticeldand,asaresult,sensethe

movement of the actuator.

Thepneumaticactuatorisoperatedbyasolenoidvalve(6,8)whichconvertsthesignalis-

sued by the control system into a binary pressure signal.

2.1 Versions

Versionwithintegratedsolenoidvalve(Type3738-50-xxx4x00x1x00x0)

The solenoid valve is integrated into the housing of the electronic limit switch. The electronic

limit switch and the solenoid valve are powered by the connected FOUNDATION™eldbus

two-wirecableaccordingtoIEC61158-2.

Versionforexternalsolenoidvalve(Type3738-50-xxx0x00x1x00x0)

The electronic limit switch and the external solenoid valve are powered by the connected

FOUNDATION™eldbustwo-wirecableaccordingtoIEC61158-2.

2.1.1 Forcedventing

Theelectroniclimitswitchcanoptionallybettedwithaforcedventing function. This func-

tionisactivatedwhenthesolenoidvalveisde-energizedafterthepowersupplyisinterrupt-

ed,causingtheactuatortomovethecontrolvalvetoitsfail-safeposition.

2.2 Operating/congurationmode

Theelectroniclimitswitchhastwomodes:theoperatingmode(RUN)andtheconguration

mode(SET).SwitchoverbetweenthetwomodesisperformedintheOperatingmodeparam-

eterupage 40.

−RUN:Operatingmode:congurationforstart-upandpartialstroketesting(PST)not pos-

sible

−SET: Congurationmode:(nooperation),congurationforstart-upandpartialstroke

testing(PST)